Mitsubishi Lancer (4A9 engine). Manual - part 119

HEADLAMP

CHASSIS ELECTRICAL

54A-138

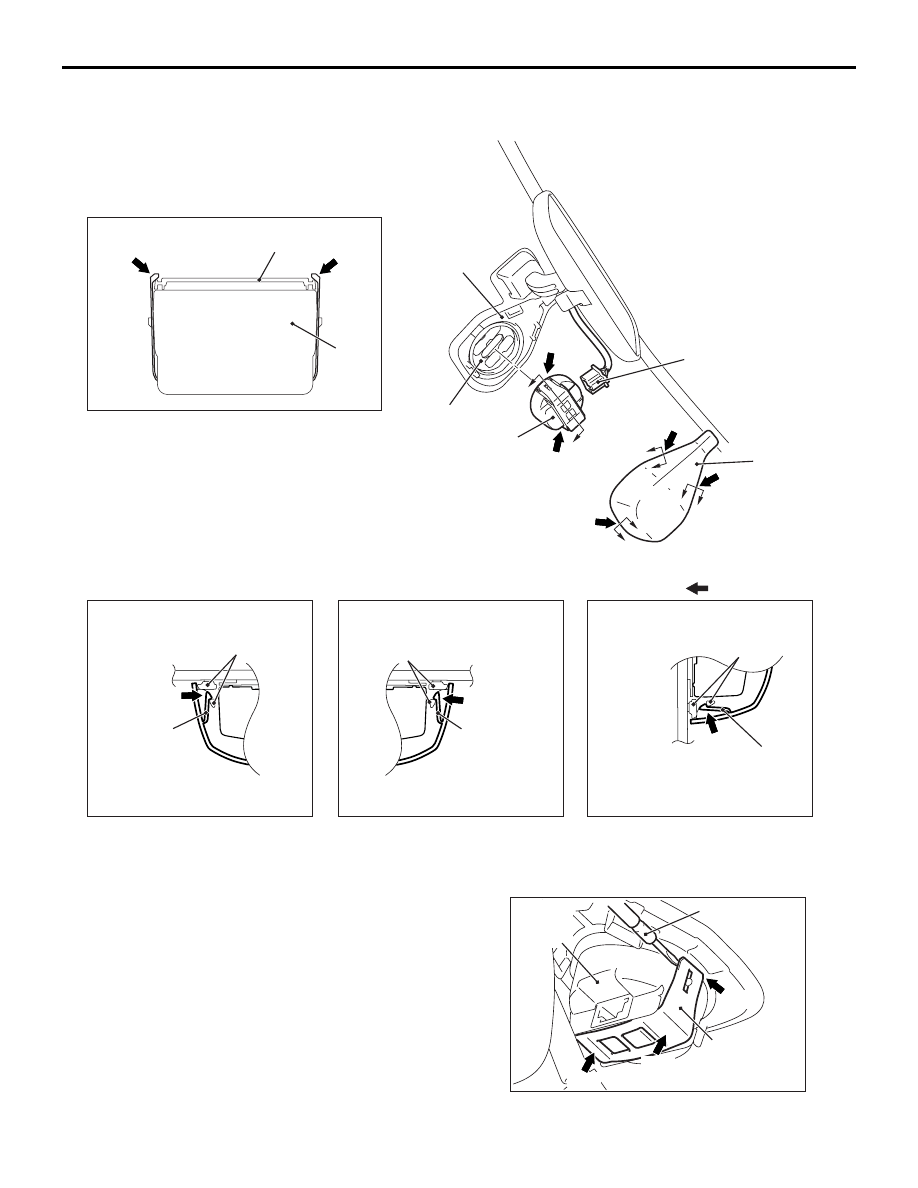

LIGHTING CONTROL SENSOR REMOVAL AND INSTALLATION

M1540108500148

REMOVAL SERVICE POINT

<<A>> LIGHTING CONTROL SENSOR REMOVAL

While pushing the clamp to the windshield side, pry

up the clamp to disengage the right and left claws

using the screwdriver (

−), and then remove the light-

ing control sensor.

AC709856AB

1

Note

: Claw positions

Section A - A

Section B - B

Section C - C

Section D - D

Optical coupler

3

D

C

B

D

C

1

1

1

Claw

Claw

Lighting control

sensor bracket

Lighting control

sensor bracket

Lighting control

sensor bracket

Lighting control

sensor bracket

Claw

Claw

Claw

Optical coupler

2

3

A

A

B

Removal Steps

1.

Lighting control sensor cover

2.

Connector

<<

A

>>

>>

A

<<

3.

Lighting control sensor

AC700066

Screwdriver (-)

AD

Claw

Lighting

control

sensor

Clamp

Push

Push