Mitsubishi Lancer (4A9 engine). Manual - part 66

AC612705

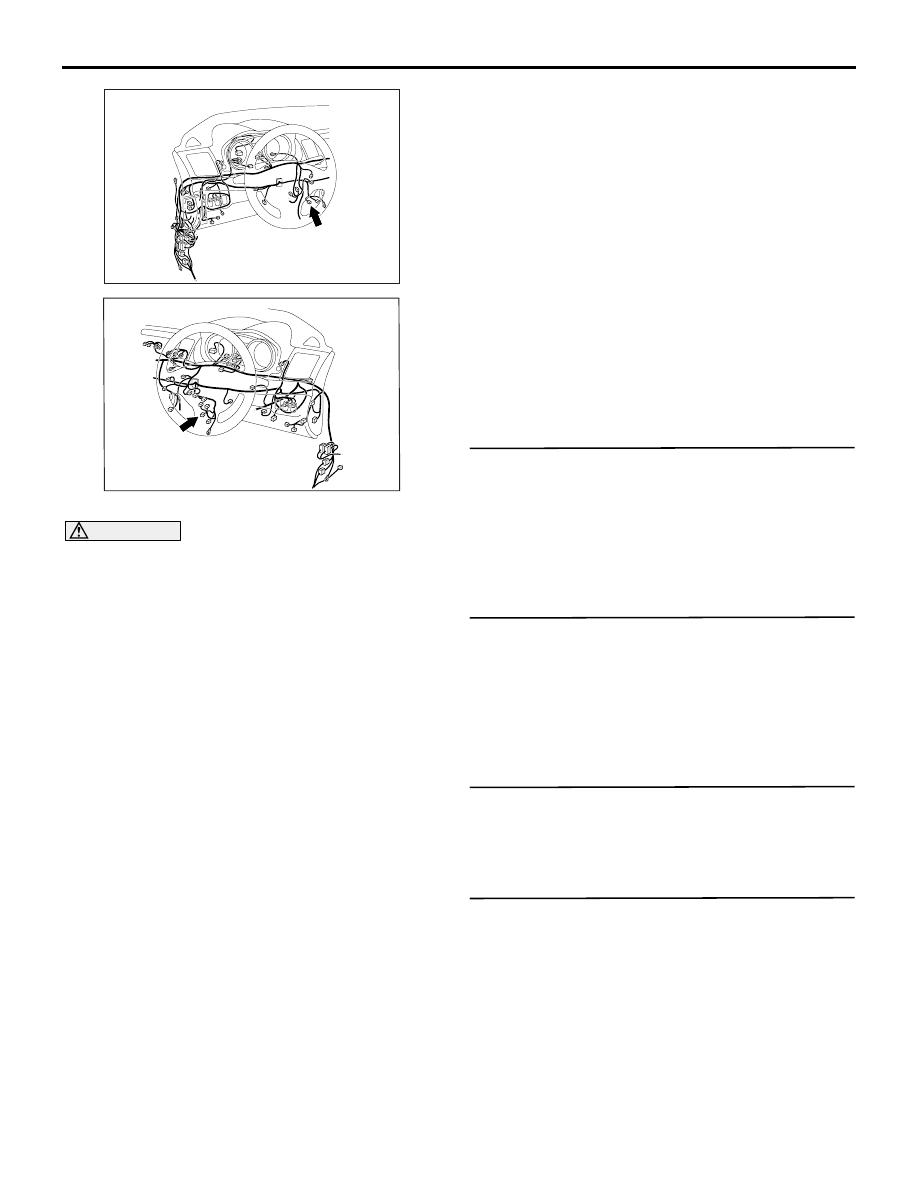

Connector: C-137 <LHD>

CG

C-137 (B)

AC701122

Connector: C-137 <RHD>

BL

TROUBLESHOOTING

ACTIVE STABILITY CONTROL SYSTEM (ASC)

35C-117

CAUTION

• If there is any problem in the CAN bus lines,

an incorrect diagnosis code may be set. Prior

to this diagnosis, diagnose the CAN bus lines

(Refer to GROUP 54C

− CAN Bus Diagnostics

Table ).

• Whenever ECU is replaced, ensure that the

CAN bus lines are normal.

• Do not drop or shock the G and yaw rate sen-

sor.

• When the G and yaw rate sensor is replaced,

always carry out calibration to make ASC-

ECU learn the neutral point (Refer to

• When the hydraulic unit (integrated with ASC-

ECU) is replaced, always carry out the calibra-

tion of the steering wheel sensor, the G and

yaw rate sensor and brake fluid pressure sen-

sor (Refer to

and

OPERATION

• ASC-ECU supplies power to the G and yaw rate

sensor at the terminal No.1.

• The G and yaw rate sensor outputs the signal to

ASC-ECU via the special CAN bus lines.

DIAGNOSIS CODE SET CONDITIONS

This diagnosis code is set if any malfunction below is

found:

Code No. C2114

• When the power supply voltage applied from

ASC-ECU to the G and yaw rate sensor is not

within the standard value range <low voltage (6.5

± 0.5 V or less)>

Code No. C2115

• When the power supply voltage applied from

ASC-ECU to the G and yaw rate sensor is not

within the standard value range <high voltage

(18.0

± 1.0 V or more)>

PROBABLE CAUSES

• Damaged wiring harness and connectors

• G and yaw rate sensor malfunction

• ASC-ECU malfunction

DIAGNOSIS PROCEDURE

STEP 1. M.U.T.-III CAN bus diagnosis

Use M.U.T.-III to diagnose the CAN bus lines.

Q: Is the check result normal?

YES :

Go to Step 2.

NO :

Repair the CAN bus lines (Refer to GROUP

54C

− CAN Bus Diagnostics Table ). On

completion, go to Step 2.

STEP 2. M.U.T.-III diagnosis code

Check that the diagnosis code No.U0125 is set in

ASC-ECU.

Q: Is the diagnosis code No.U0125 set?

YES :

Troubleshoot for the diagnosis code (Refer

to

NO :

Go to Step 3.

STEP 3. Diagnosis code recheck

Q: Are the diagnosis codes No. C2114 or C2115 set?

YES :

Go to Step 4.

NO :

This diagnosis is complete.

STEP 4. M.U.T.-III data list

Check the following data list (Refer to

• Item 08: Lateral G sensor

• Item 09: G sensor

• Item 12: Yaw rate sensor

Q: Is the check result normal?

YES :

Go to Step 12.

NO :

Go to Step 5.