Mitsubishi Lancer (4A9 engine). Manual - part 23

D998727

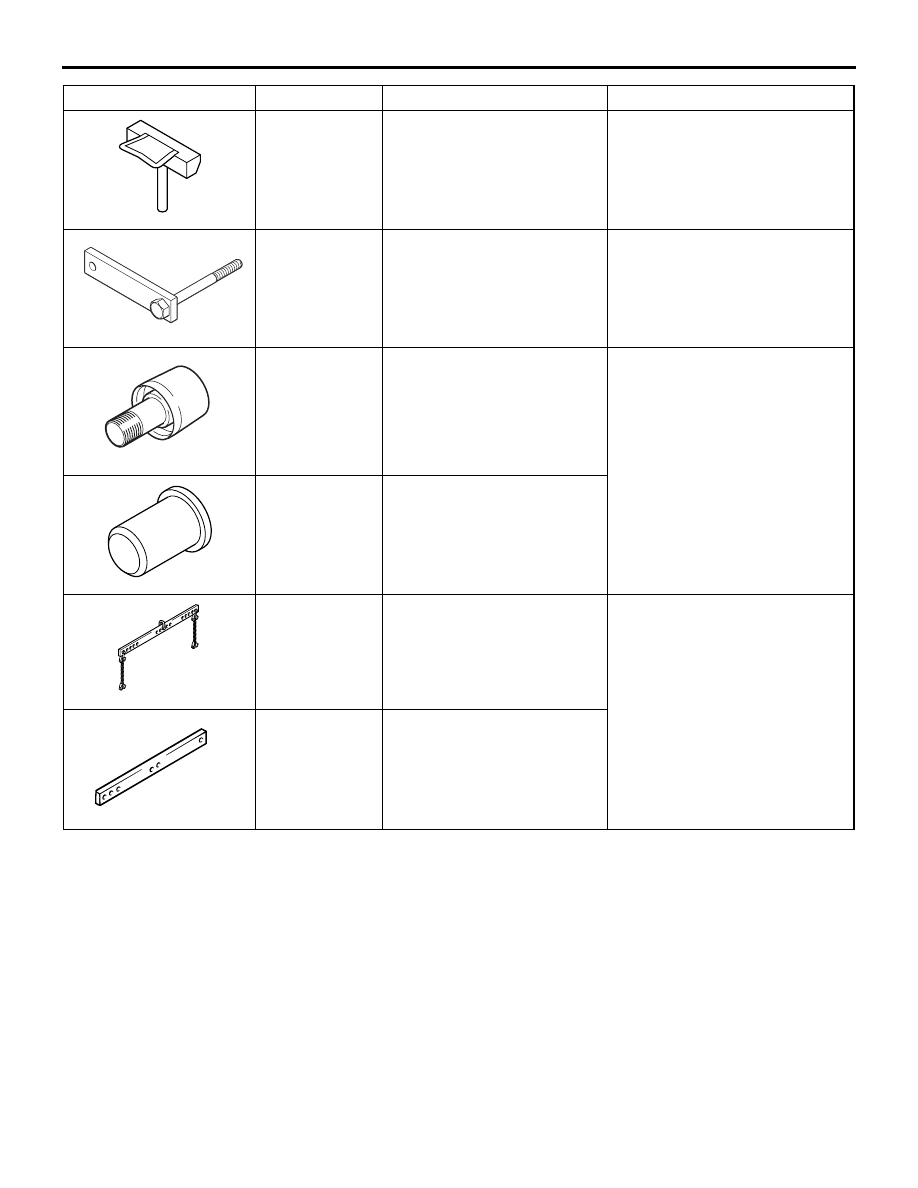

SPECIAL TOOLS

ENGINE MECHANICAL <4A9>

11A-6

MD998727

Oil pan FIPG cutter

Engine oil pan removal

D998781

MD998781

Flywheel stopper

Supporting the flywheel

assembly <M/T> or drive plate

assembly <A/T>

B991993

MB991993

Crankshaft front oil seal

guide

Crankshaft front oil seal

installation

MB990699

Differential oil seal installer

B991454

MB991454

Engine hanger balancer

Supporting the engine and

transmission assembly

NOTE: Special tool MB991454

is a part of engine hanger

attachment set MB991453.

B991527

MB991527

Hanger

Tool

Number

Name

Use