Mitsubishi Lancer (4A9 engine). Manual - part 15

PRECAUTIONS BEFORE SERVICE

GENERAL

00-57

NOTE:

.

•

*

: The setting can be changed by the option cod-

ing.

OPTION CODING

CAUTION

• If there is any item indicated by the option

coding after equipment change, set ETACS-

ECU so that the option coding data corre-

sponds with the equipment content. Pay

attention to that the concerned functions and

systems do not work normally if the setting

does not correspond with the equipment.

• With the ETACS functions being customised,

if any of the ETACS-ECU option coding items

are changed, the customised contents are

reset. In such case, the functions need to be

recustomised.

The engine-ECU <4A9, 4B1, 4J1> or ETACS-ECU

option coding data can be checked or changed by

operating M.U.T.-III.

• How to check option coding data

1. Connect the M.U.T.-III. Refer to .

2. Select "MPI/GDI/DIESEL" <4A9, 4B1, 4J1> or

"ETACS" on the system selection screen.

3. Select "Coding."

4. Select "Option Coding Information."

5. Check the displayed option coding informa-

tion.

• How to change option coding data

1. Connect the M.U.T.-III. Refer to .

2. Select "MPI/GDI/DIESEL" <4A9, 4B1, 4J1> or

"ETACS" on the system selection screen.

3. Select "Coding."

4. Select "Option Coding."

5. Change to correct option coding data.

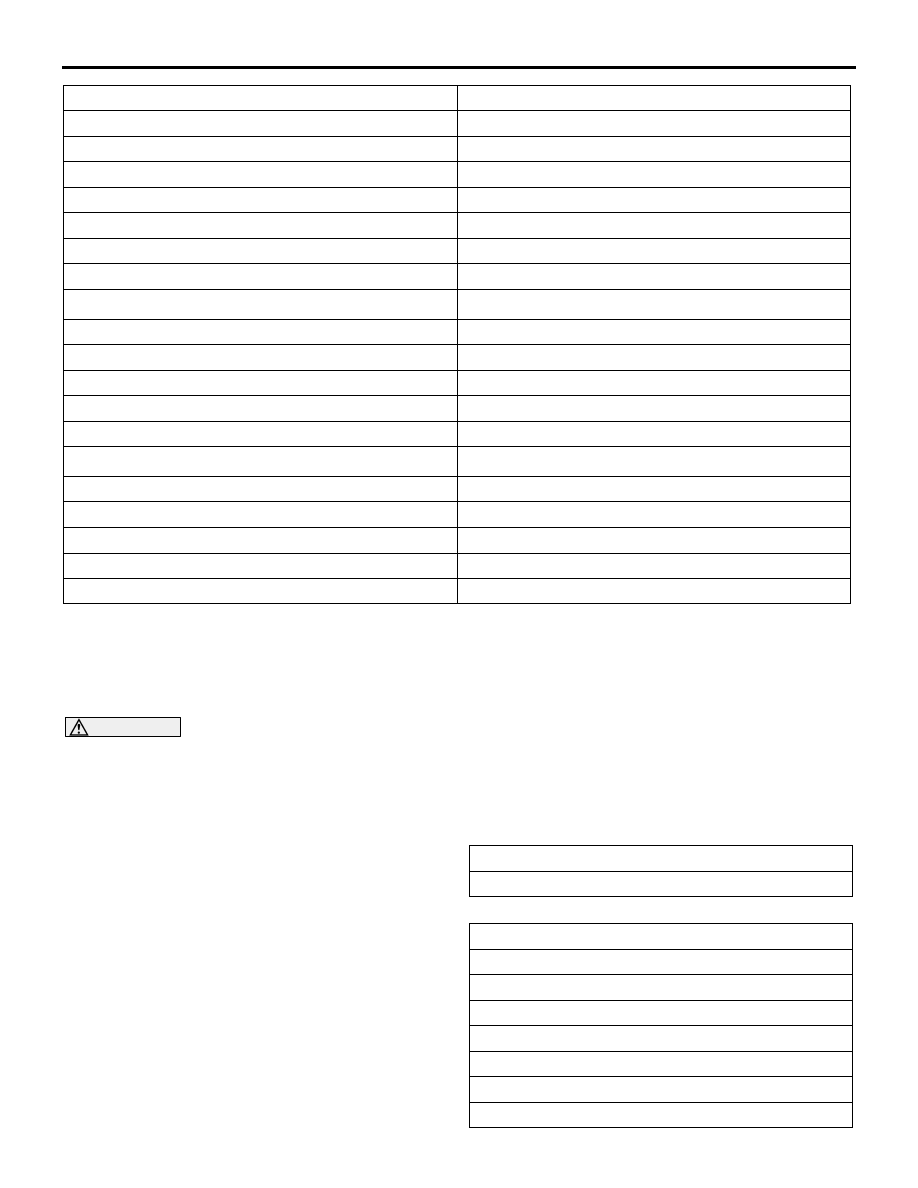

LIST <Engine-ECU (4A9, 4B1, 4J1)>

Item name

Cruise control

LIST <ETACS-ECU>

Trailer turn detection

Present

Shift Lever

Not present

AFS/ACL/Leveling

Not present or Present

Satellite radio

Not present

Auto Stop & Go (AS&G)

Not present or Present

Display opening type

MMC

GSI system

Not present or Present

DRL function

*

NotPresent/Chg Ok or Present/Chg Ok

FACU

Not present

S-AWC control display

Not available

Diesel particulate filter

Not present or Present

Language mode

Available

WSS

Not present

Door Unlock Mode Customize

*

Disabled or Enable

RLS overwipe type

Type 1

RLS WS type

Type 2 (Green)

Launch gear block alarm

Not present

Interior illumination customize

Disabled

Security sensor gain setting

Type 1 or Type 5 or Type 6

Item name

Initial value

Item name

Auto lamp CNTL

Keyless

AUDIO (CAN)

Rain Light Sensor

AUDIO/S.RADIO type

Number of speaker

Seat material