Mitsubishi Lancer (4A9 engine). Manual - part 3

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE POINTS

GENERAL

00-9

NOTE:

.

•

For details on how to use the M.U.T.-III, refer to

the "M.U.T.-III operation manual."

•

For the vehicles with security alarm sensor, when

the M.U.T.-III is connected, if the ignition switch is

turned to the "ON" position and the closed hood

is opened, the security alarm siren sounds short.

This short security alarm siren does not indicate

malfunction. Therefore, ignore it and carry out

diagnosis using M.U.T.-III.

•

If the ignition switch is turned to the "ON" position

with M.U.T.-III connected to the vehicle, head-

lamp automatic levelling warning is displayed on

the multi-information display in the combination

meter. This symptom occurs because the head-

lamp automatic levelling-ECU enters the diagno-

sis mode when the M.U.T.-III is connected to the

diagnosis connector, and it does not indicate mal-

function. Therefore, ignore the indicator display

and carry out diagnosis using M.U.T.-III. (When

the M.U.T.-III starts communication with the ECU,

the indicator display disappears.)

1. Ensure that the ignition switch is at the "LOCK"

(OFF) position.

2. Start up the personal computer.

3. Connect special tool M.U.T.-III USB cable

(MB991827) to V.C.I. (MB991824) and the

personal computer.

4. Connect special tool M.U.T.-III main harness A

(MB991910) to the V.C.I.

5. Connect the M.U.T.-III main harness A to the

diagnosis connector of the vehicle.

6. Turn the V.C.I. power switch to the "ON" position.

NOTE: When the V.C.I. is energized, the V.C.I.

indicator lamp will be illuminated in a green col-

our.

7. Start the M.U.T.-III system on the personal

computer and turn the ignition switch to the "ON"

position.

8. Read the diagnosis code.

NOTE: When storing the diagnosis code as refer-

ence information, the freeze frame data obtains the

data when the diagnosis code is confirmed, and then

stores the ECU status of that time. By analysing

each data using M.U.T.-III, troubleshooting can be

carried out efficiently.

9. Disconnecting the M.U.T.-III is the reverse of the

connecting sequence, making sure that the

ignition switch is at the "LOCK" (OFF) position.

ERASING DIAGNOSIS CODE

CAUTION

Before connecting or disconnecting the M.U.T.-

III, turn the ignition switch to the "LOCK" (OFF)

position.

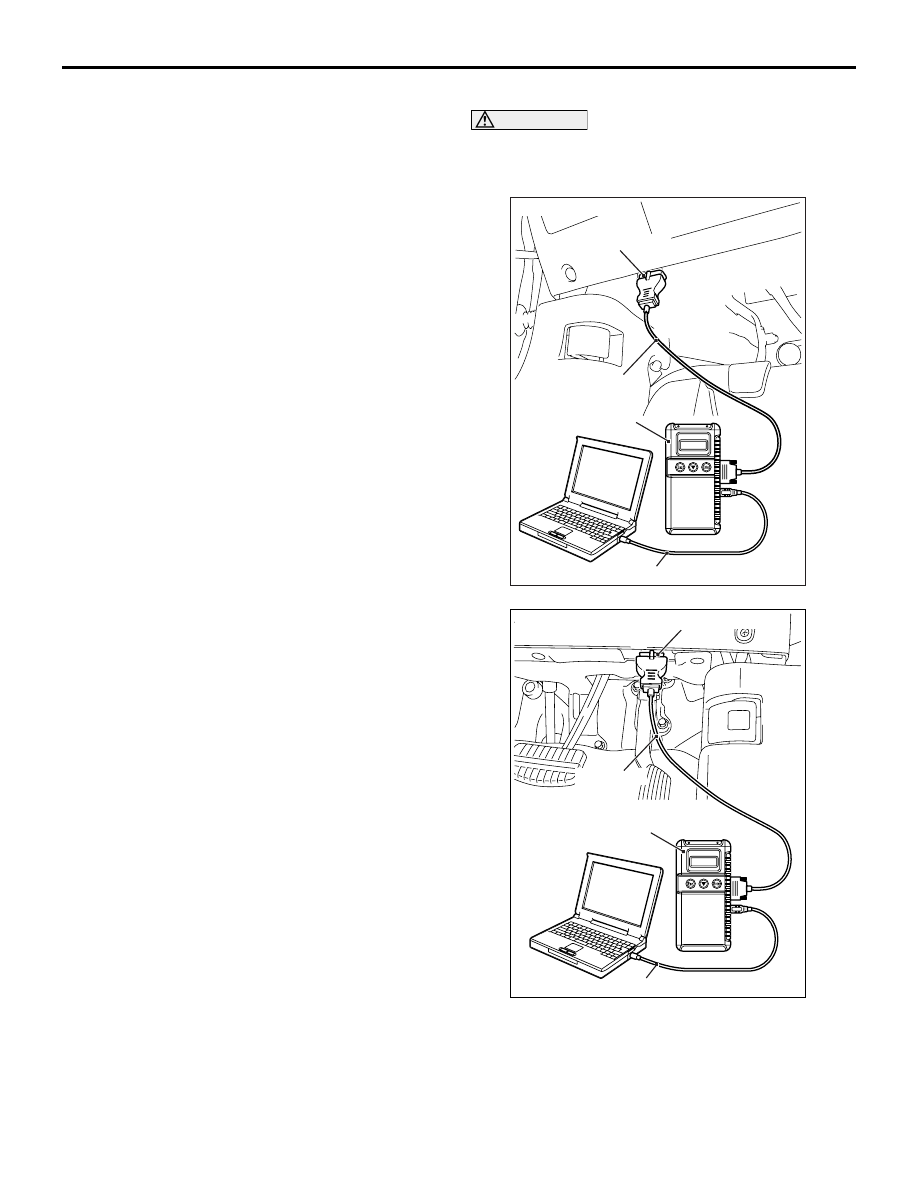

AC608435

MB991827

MB991824

MB991910

AB

Diagnosis connector

<LH drive vehicles>

AC700191

MB991827

MB991824

AB

Diagnosis connector

<RH drive vehicles>

MB991910

Connect the M.U.T.-III to the diagnosis connector,

and erase the diagnosis code. The procedure is the

same as "How to Read Diagnosis Code ."