Mitsubishi Evolution X. Manual - part 961

REAR COMBINATION LIGHT

TSB Revision

CHASSIS ELECTRICAL

54A-205

STEP 2. Check headlight assembly (LH) connector A-40,

rear combination light (LH) connector F-25, taillight (LH)

connector F-24, license plate light connector F-18 (LH) and

F-15 (RH) for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Is headlight assembly (LH) connector A-40, rear

combination light (LH) connector F-25, taillight (LH)

connector F-24, license plate light connector F-18 (LH)

and F-15 (RH) in good condition?

YES : Go to Step 3.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

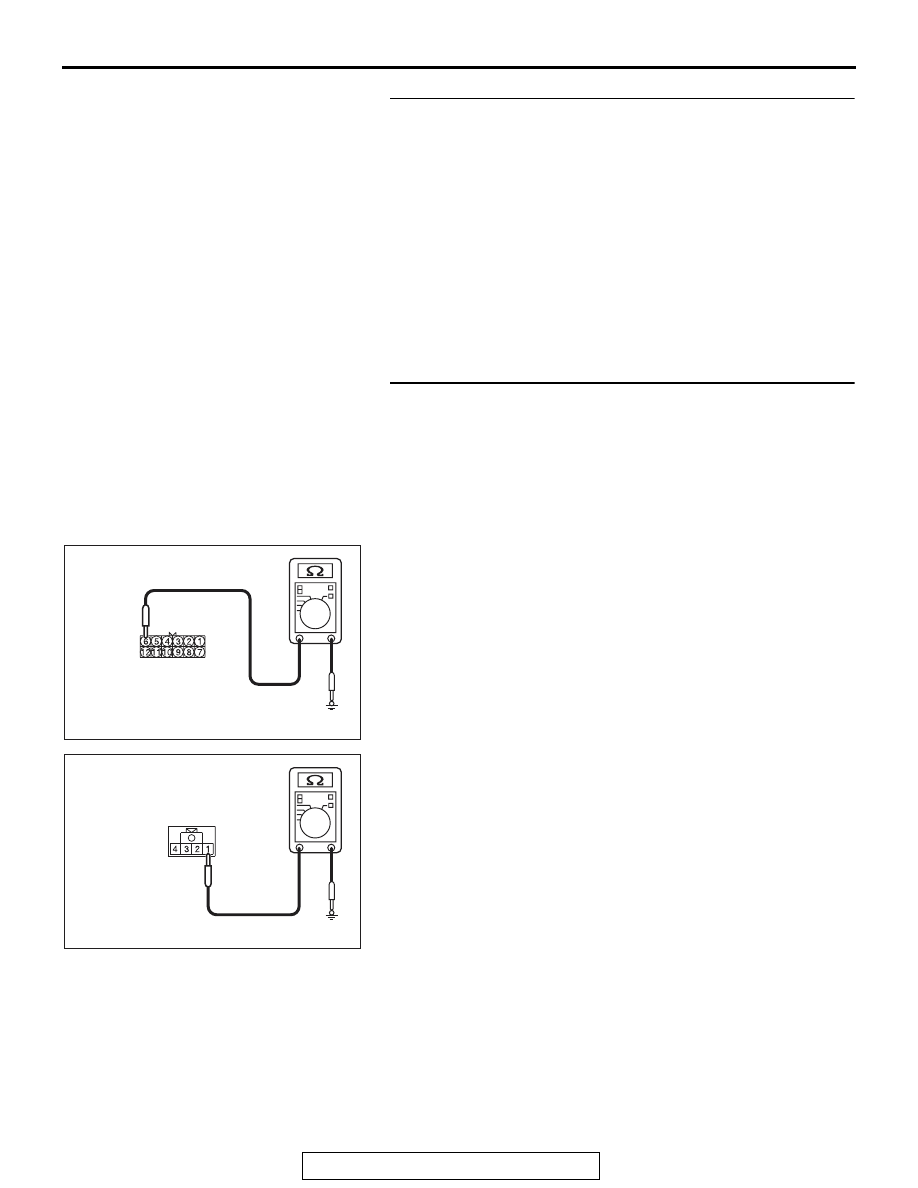

STEP 3. Resistance measurement at headlight assembly

(LH) connector A-40, rear combination light (LH) connector

F-25, taillight (LH) connector F-24, license plate light

connector F-18 (LH) and F-15 (RH).

(1) Disconnect the connector, and measure at the wiring

harness side.

(2) Measure the resistance between the connector of light

which does not illuminate and the body ground.

•

Measure the resistance between headlight assembly

(LH) connector A-40 (terminal 6) and the body ground.

•

Measure the resistance between rear combination light

(LH) connector F-25 (terminal 1) and the body ground.

AC709322 AD

Harness side: A-40

AC709322 AF

Harness side: F-25