Mitsubishi Evolution X. Manual - part 959

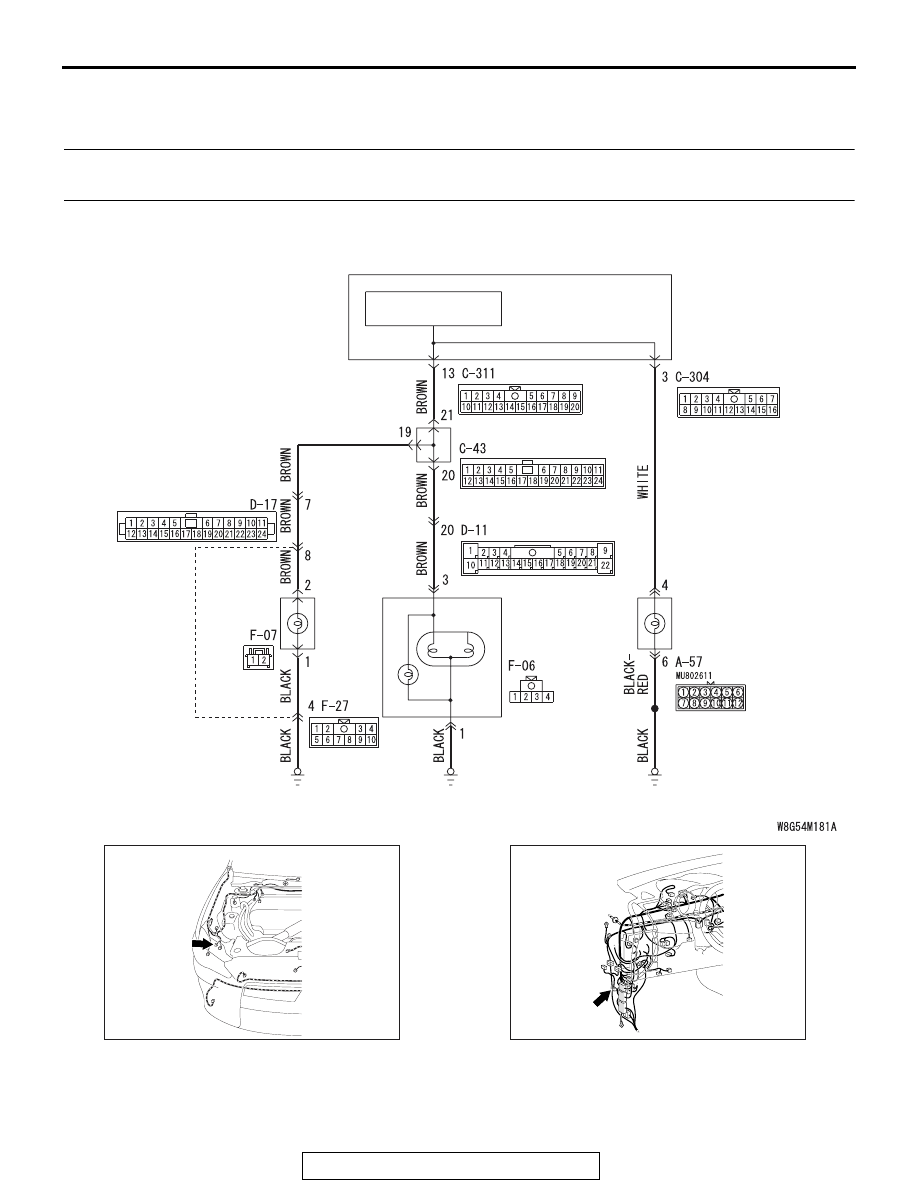

REAR COMBINATION LIGHT

TSB Revision

CHASSIS ELECTRICAL

54A-197

DIAGNOSTIC TROUBLE CODE PROCEDURES

DTC B16A0: Taillight (RH) circuit open (Open circuit in taillight (RH) or position light (RH))

DTC B16A7: Taillight (RH) circuit short (Short circuit in taillight (RH) or position light (RH))

ETACS-ECU

JOINT CONNECTOR

TAILLIGHT

CONTROL CIRCUIT

Taillight and Position Light Circuit

REAR

COMBINATION

LIGHT

(TAILLIGHT: RH)

TAILLIGHT

(RH)

HEADLIGHT

ASSEMBLY

(POSITION

LIGHT: RH)

AC708948AH

Connector: A-57

A-57 (B)

AC708950

Connector: C-43

BG

C-43 (B)