Mitsubishi Evolution X. Manual - part 912

BATTERY

TSB Revision

CHASSIS ELECTRICAL

54A-9

BATTERY TEST

M1541001201509

BATTERY TESTING PROCEDURE

STEP 1. Check the battery cables.

Remove the negative cable, then the positive cable.

Check for dirty or corroded connections.

Q: Are the battery cables dirty or have corroded

connections?

YES :

Clean the battery cables. Then go to Step 2.

NO :

Go to Step 2.

STEP 2. Check the battery post.

Check for loose battery post.

Q: Are the battery posts faulty?

YES :

Replace the battery. Then go to Step 4.

NO :

Go to Step 3.

STEP 3. Check the battery case.

(1) Remove the hold-downs.

(2) Check for broken/cracked case.

Q: Is the battery case faulty?

YES :

Replace the battery.

NO :

Go to Step 4.

STEP 4. Check the open circuit voltage.

(1) Turn headlights on for 15 seconds.

(2) Turn headlights off for two minutes to allow

battery positive voltage to stabilize.

(3) Disconnect the battery cables.

(4) Read open circuit voltage.

Q: Is open circuit voltage 12.4 volts or more?

YES :

Go to Step 6.

NO :

Go to Step 5.

STEP 5. Battery charging

With 5 amp from the current voltage, charge the bat-

tery by referring to the Graph 1.

Q: Is open circuit voltage 12.4 volts or more?

YES :

Go to Step 6.

NO :

Replace the battery.

STEP 6. Check the load test.

(1) Connect a load tester to the battery.

(2) Load the battery at the recommended discharge

rate (See LOAD TEST RATE CHART) for 15

seconds.

(3) Read voltage after 15 seconds, then remove

load.

(4) Compare the measured value with the minimum

voltage (See LOAD TEST CHART).

Q: Is the voltage higher than minimum voltage?

YES :

The battery is normal.

NO :

Replace the battery.

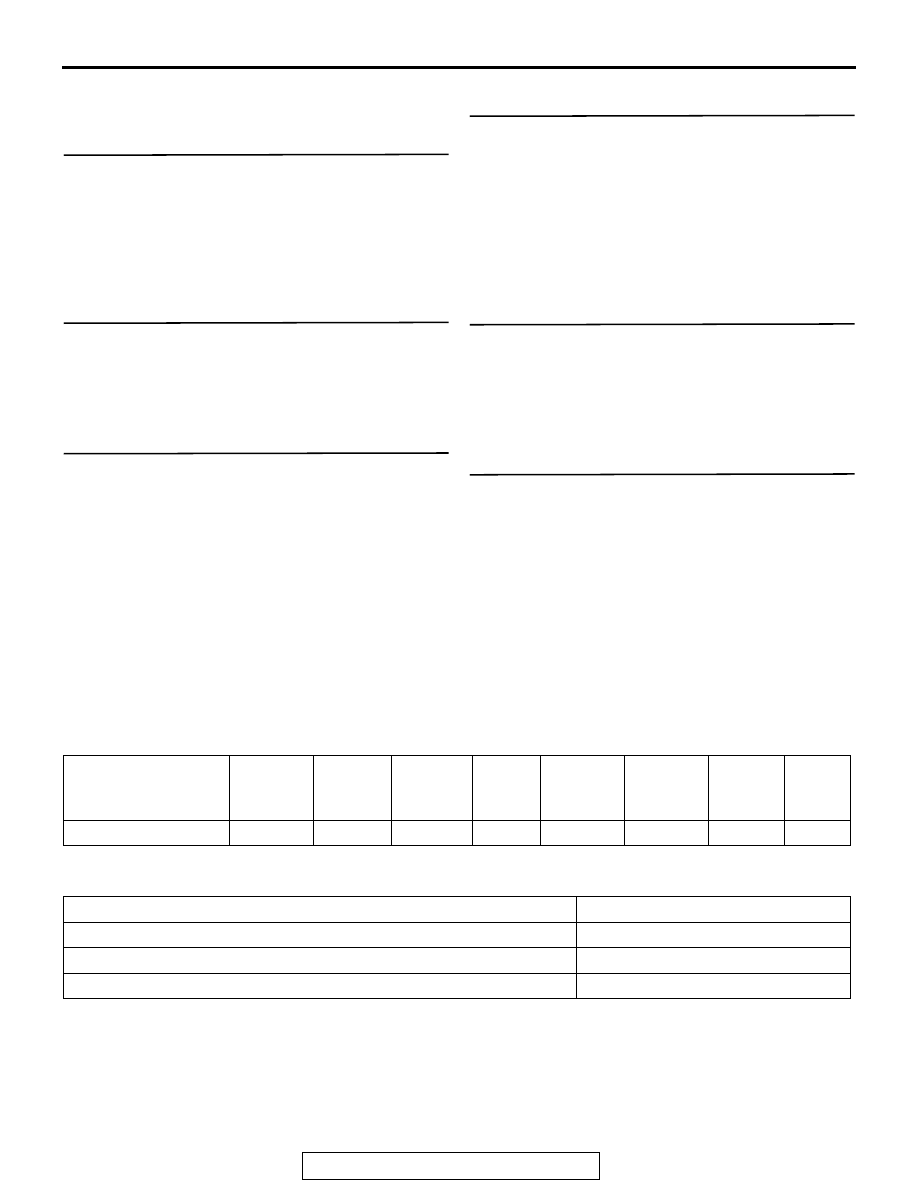

LOAD TEST CHART

LOAD TEST RATE CHART

Temperature

° C

(

° F)

21 (70)

and

above

16 (60)

10 (50)

4 (40)

−1 (30)

−7 (20)

−12 (10) −18 (0)

Minimum voltage

9.6

9.5

9.4

9.3

9.1

8.9

8.7

8.5

Load test

220 amps

Cranking ratio [

−18° C (0° F)]

450 amps

Reserve capacity

84 minutes

Application

S65D26L