Mitsubishi Evolution X. Manual - part 904

TRAILING ARM

TSB Revision

REAR SUSPENSION

34-17

TRAILING ARM

REMOVAL AND INSTALLATION

M1341002200981

CAUTION

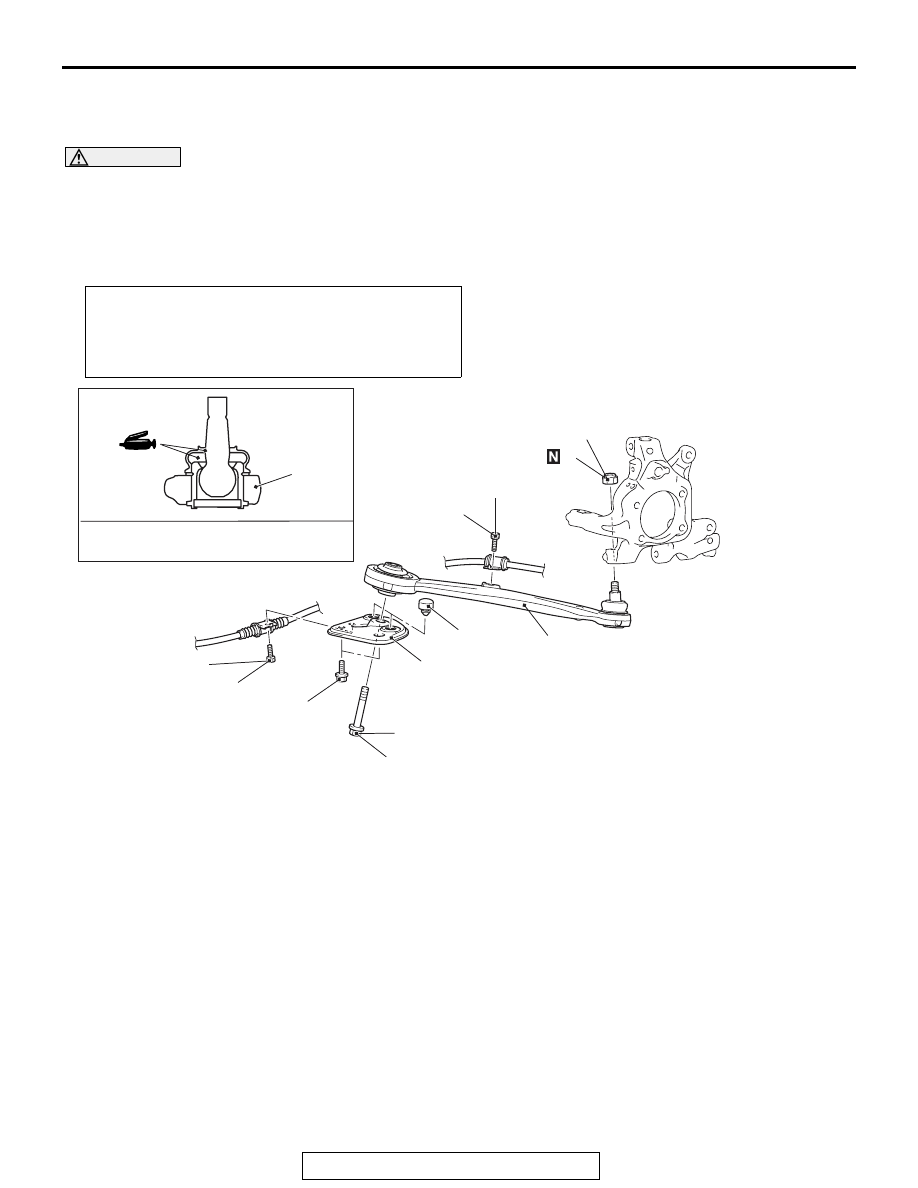

• Do not damage the trailing arm ball joint dust cover during maintenance. If it is damaged, replace

the trailing arm ball joint dust cover (

).

•

Post-installation operation

• Using your fingers, press the Ball Joint Dust Cover to

check for a crack or damage.

• Wheel alignment check and adjustment (Refer to

AC705374

AC705373AB

AB

81 ± 6 N·m

60 ± 4 ft-lb

110 ± 11 N·m

81 ± 8 ft-lb

11 ± 2 N·m

98 ± 17 in-lb

1

3

2

5

6

4

1

5

11 ± 2 N·m

98 ± 17 in-lb

110 ± 11 N·m

81 ± 8 ft-lb

*

Specified grease: Multipurpose grease

SAE J310, NLGI No.2 or equivalent

Removal steps

1.

Parking brake cable mounting bolt

<<

A

>>

>>

A

<<

2.

Self-locking nut

3.

Trailing arm assembly mounting

bolt

4.

Trailing arm bracket assembly

5.

Trailing arm assembly

6.

Stopper

The part indicated by

*

is the bolt with friction coefficient stabilizer. In removal, ensure there is no

damage, clean dust and soiling from the bearing and thread surfaces, and tighten them to the

specified torque.

Required Special Tool:

• MB991897 or MB992011: Ball Joint Remover

Removal steps (Continued)