Mitsubishi Evolution X. Manual - part 902

ON-VEHICLE SERVICE

TSB Revision

REAR SUSPENSION

34-9

ON-VEHICLE SERVICE

REAR WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1341011000963

1. Before the wheel alignment measurement, adjust the rear

suspension, wheel, and tires in good condition.

2. Park the vehicle on a level surface to measure the wheel

alignment.

.

CAMBER

Standard value:

− 1° 00' ± 0° 30' (difference between left

and right within 0

° 30')

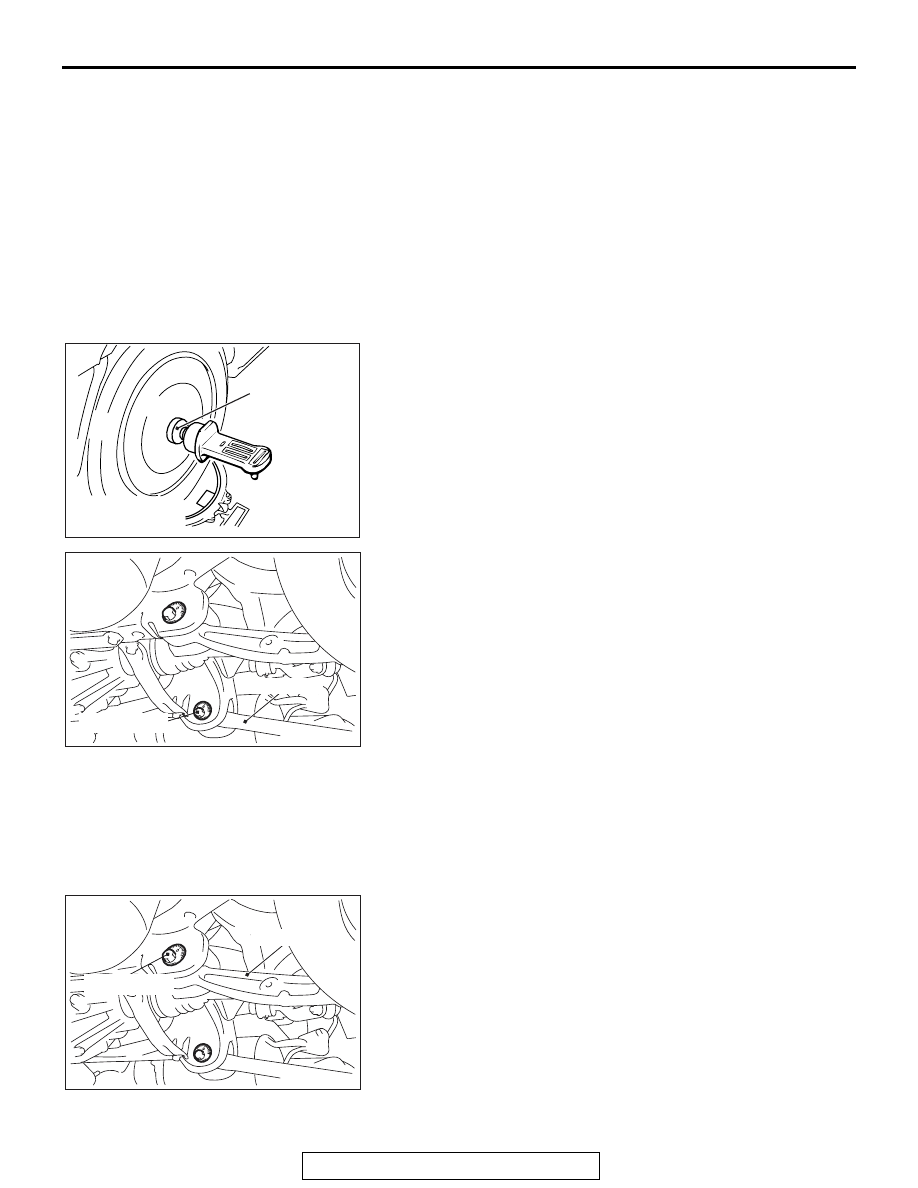

AC208980AI

MB991004

Tighten the wheel alignment gauge attachment (Special tool:

MB991004) to the specified torque, then measure the camber.

Tightening torque: 144

− 176 N⋅ m (107 − 129 ft-lb)

If camber is not within the standard value, adjust by following

procedures.

AC704801AB

Adjusting bolt

Lower arm

1. Turn the lower arm adjusting bolt (camber adjusting bolt) to

adjust.

Left wheel: Turning clockwise

→ (+) camber

Right wheel: Turning clockwise

→ (−) camber

2. After adjusting the camber, the toe should be adjusted.

.

TOE-IN

Standard value: 3

± 2 mm (0.12 ± 0.08 inch)

It toe-in is not within the standard value, adjust by following pro-

cedures.

1. Be sure to adjust the camber before making toe adjustment.

AC704801AC

Adjusting bolt

Control link

Turn the adjusting bolt (toe adjusting bolt: control link mounting

bolt which is located on the inner side of the body) to adjust.

Left wheel: Turning clockwise

→ (+) toe-in

Right wheel: Turning clockwise

→ (−) toe-in