Mitsubishi Evolution X. Manual - part 775

DIAGNOSIS

TSB Revision

ACTIVE SKID CONTROL SYSTEM (ASC)

35C-107

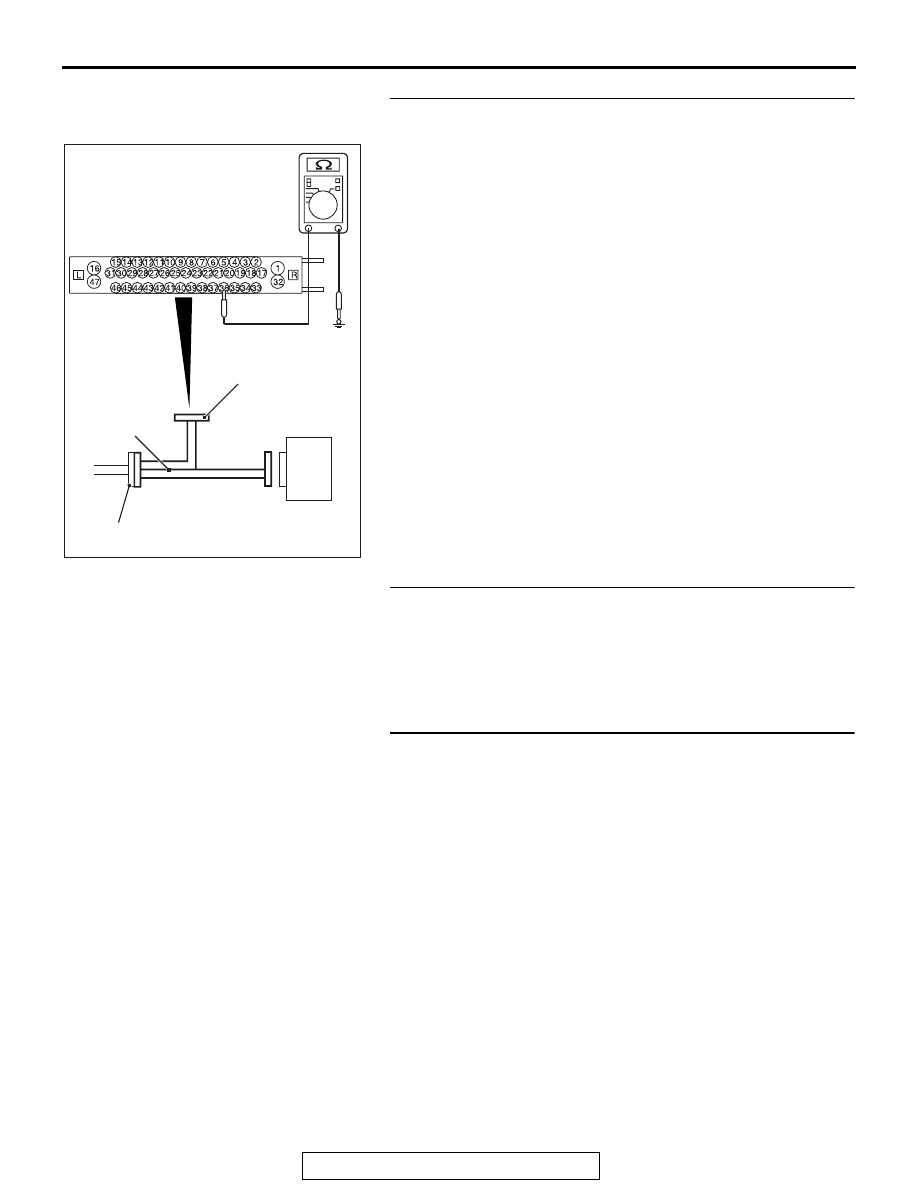

STEP 6. Resistance measurement at A-05 ASC-ECU

connector

(1) Disconnect the ASC-ECU connector, connect the ASC

check harness (Special tool: MB991997) to the wiring

harness-side connector, and then measure at the special

tool connector side.

NOTE: Do not connect the special tool to ASC-ECU.

(2) Measure the resistance between the wheel speed sensor

circuit power supply terminal (signal terminal) No. 36 and

the body ground as well as between the ground terminal

No. 37 and the body ground.

OK: No continuity

Q: Is the check result normal?

YES : Go to Step 9.

NO (Not normal at the terminal No. 36 or 37) : Go to Step

7.

STEP 7. Connector check: A-05 ASC-ECU connector, C-45

intermediate connector, D-18 wheel speed sensor <RL>

connector

Q: Is the check result normal?

YES : Go to Step 8.

NO : Repair the defective connector. Then go to Step 17.

STEP 8. Wiring harness check between A-05 ASC-ECU

connector terminal No. 36 and D-18 wheel speed sensor

<RL> connector terminal No. 1, and between A-05

ASC-ECU connector terminal No. 37 and D-18 wheel speed

sensor <RL> connector terminal No. 2

• Short circuit check of wheel speed sensor <RL> circuit

Q: Is the check result normal?

YES : Replace the wheel speed sensor <RL>. (Refer to

.) Then go to Step 17.

NO : Repair the wiring harness. Then go to Step 17.

AC400817CI

ASC-ECU

MB991997

Check harness

A-05 ASC-ECU

harness connector