Mitsubishi Evolution X. Manual - part 762

DIAGNOSIS

TSB Revision

ACTIVE SKID CONTROL SYSTEM (ASC)

35C-55

DTC C1027: Abnormality in RL wheel speed sensor signal

CAUTION

• If there is any problem in the CAN bus lines, an incor-

rect diagnostic trouble code may be set. Prior to this

diagnosis, diagnose the CAN bus lines.

• Whenever the ECU is replaced, ensure that the CAN

bus lines are normal.

• When the hydraulic unit (integrated with ASC-ECU) is

replaced, always perform the calibration of steering

wheel sensor, G and yaw rate sensor, brake fluid pres-

sure sensor, cut valve, and inlet valve.(Refer to

.)

.

CIRCUIT OPERATION

• Each wheel speed detecting section is a kind of a pulse

generator. It consists of the encoder (plate on which the

north and south pole of magnet are arranged alternately) for

detecting the wheel speed, which rotates at the same speed

of the wheels, and the wheel speed sensor. This detecting

section outputs the frequency pulse signals in proportion to

the wheel speed.

• The pulse signals generated by the wheel speed detecting

section are sent to ASC-ECU. ASC-ECU uses the fre-

quency of the pulse signals to determine the wheel speed.

.

AC708948

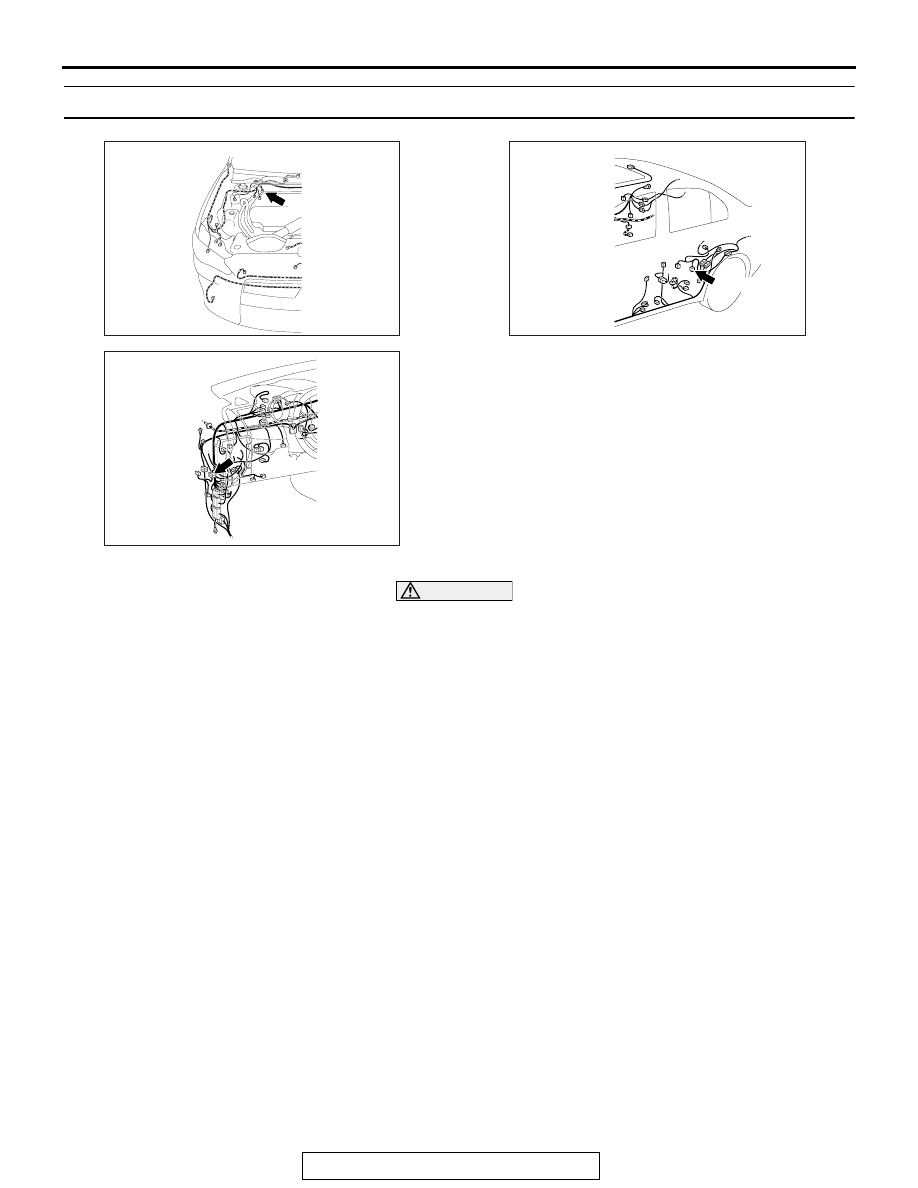

Connector: A-05

A-05 (B)

AB

AC708950

Connector: C-45

AD

AC708955

Connector: D-18

D-18 (B)

AE