Mitsubishi Evolution X. Manual - part 454

DIAGNOSIS <TC-SST>

TSB Revision

TWIN CLUTCH- SPORTRONIC SHIFT TRANSMISSION (TC-SST)

22C-273

.

OBD-II DRIVE CYCLE PATTERN

<RATIONALITY>

Each value of failure condition 1 or failure condition 2

(Logic Flow Charts (Monitor Sequence) <Rational-

ity>) returns to the normal value and remains in the

state for 500 milliseconds.

.

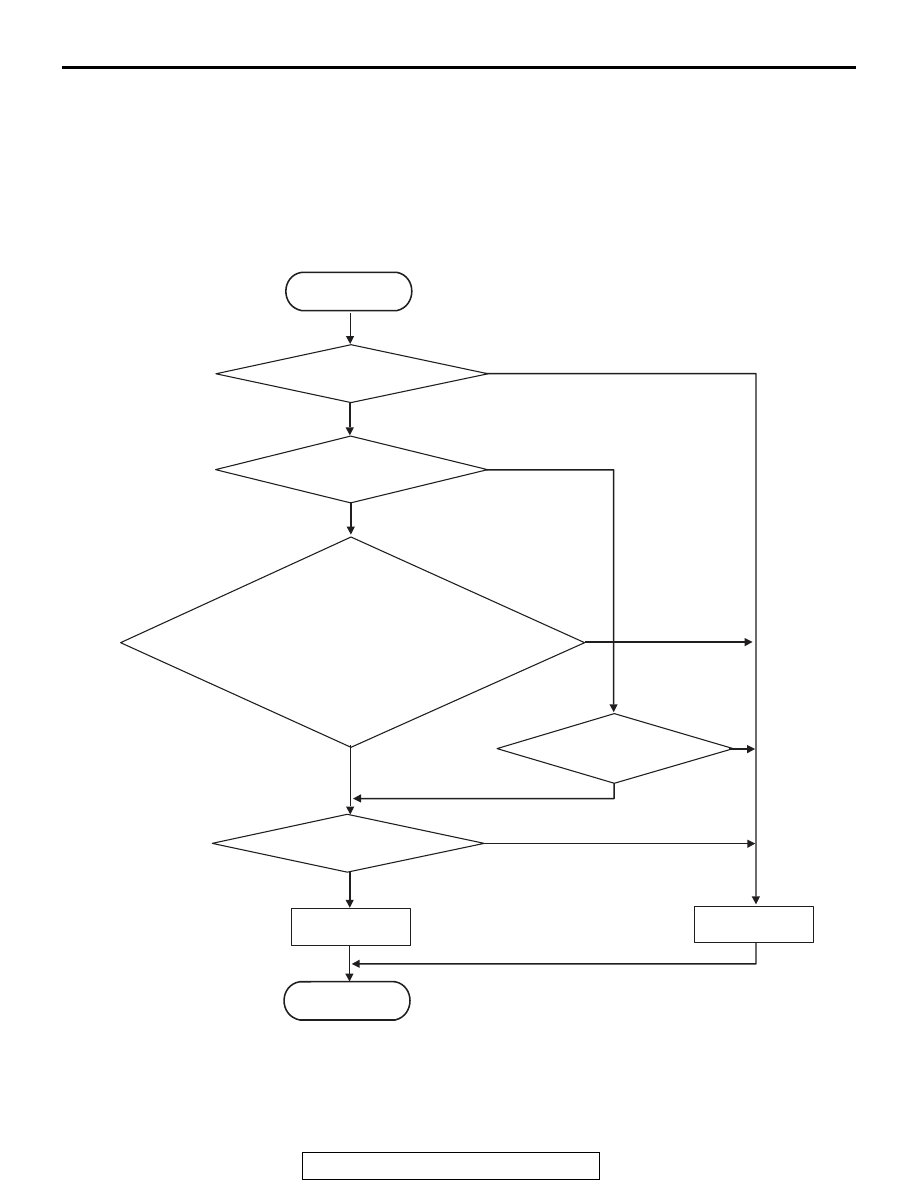

LOGIC FLOW CHARTS (Monitor Sequence) <Rationality - plausibility failure>

.

AC710601

No

Yes

Malfunction

No

Yes

Monitoring condition met

No

Yes

Yes

Engine speed signal

status = not SNA

Continuous failure

for 250 msec

Input shaft speed*

1

> 12,800 r/min

START

END

Yes

|Input shaft speed*

1

| > (min(max(engine speed,

input shaft target speed [current gear]*

1

,

input shaft target speed [target gear]*

1

) + 3,000 r/min,

12,800 r/min)

Good

No

No

*

1

:In case of input shaft 1 (odd) speed sensor monitor, this is speed of input shaft (odd).

In case of input shaft 2 (even) speed sensor monitor, this is speed of input shaft (even).