Mitsubishi Evolution X. Manual - part 366

DIAGNOSIS <S-AWC(SUPER ALL WHEEL CONTROL)>

TSB Revision

MANUAL TRANSAXLE

22A-113

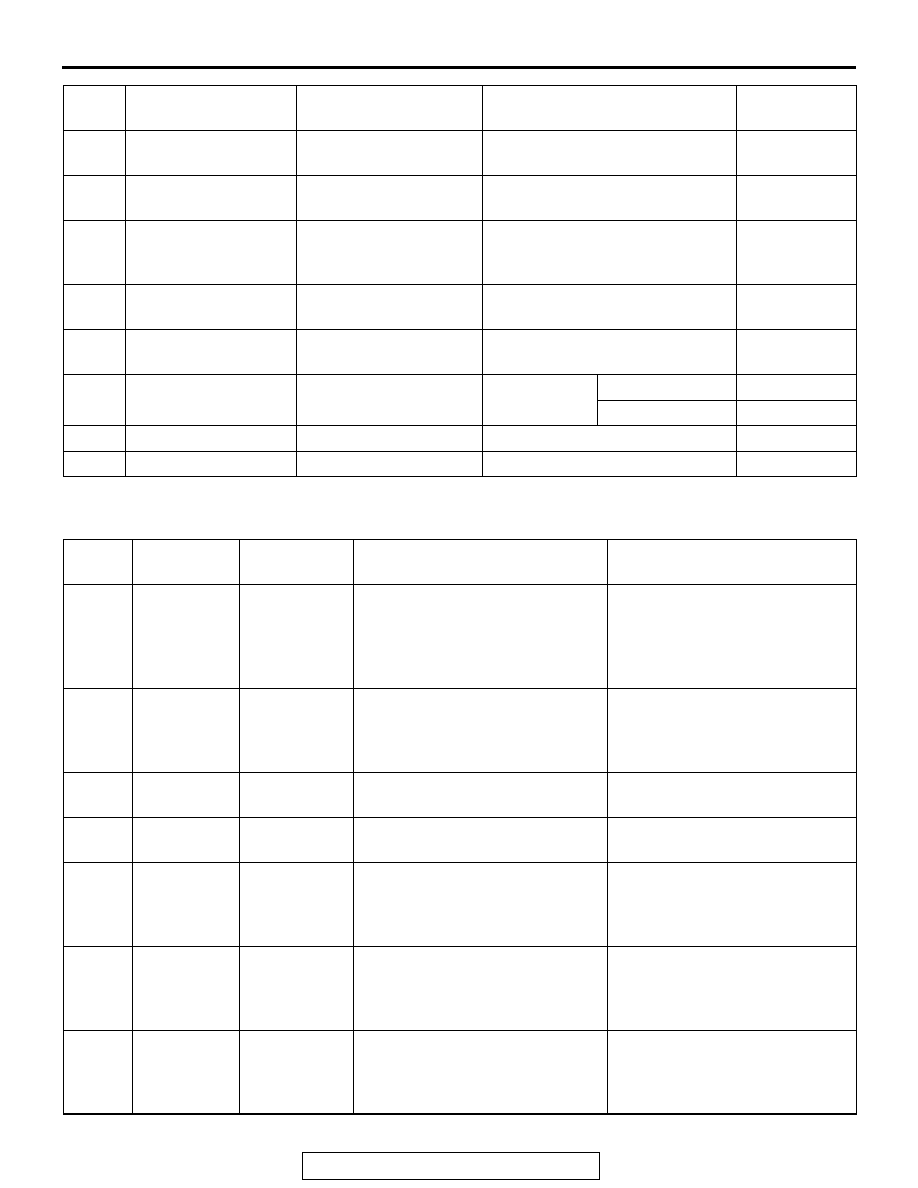

SPECIAL FUNCTION REFERENCE TABLE

M1221011300062

ACTUATOR TEST TABLE

97

Yaw rate sensor

(adjusted value)

Yaw rate sensor

(Correction amount)

Ignition switch: ON

−6 − 6 deg/s

98

SAS (adjusted value) Steering sensor

(Correction amount)

Ignition switch: ON

−15 − 15 deg

99

Lateral G

sensor(adjusted

value)

Lateral G sensor

(Correction amount)

Ignition switch: ON

−1.7 − 1.7 m/s

2

100

Longitudinal G

(adjusted value)

Longitudinal G sensor

(Correction amount)

Ignition switch: ON

−3 − 3 m/s

2

101

Chassis Number

writing counter

Chassis number writing

count

Ignition switch: ON

Writing count

102

Chassis Number

(original) lock

Chassis number

(original) lock

Ignition

switch: ON

Locked

Lock

Unlocked

Unlock

103

Mileage counter

Mileage counter

Ignition switch: ON

Counter value

104

Coding counter

Coding count

Ignition switch: ON

Coding count

Item

No.

Display on scan tool Item name

Check conditions

Normal

conditions

Item

No.

Display on

scan tool

Check items Test content

Normal conditions

1

ACD air

bleeding

Air bleeding

<ACD>

According to the steering angle of

steering wheel, energize the

proportioning valve, and operate

the proportioning valve for 5

minutes.

No air comes out from the

bleeder screw established to the

transfer.

2

AYC air

bleeding

Air bleeding

<AYC>

According to the steering angle of

steering wheel, energize the

proportioning valve, and operate

the direction valve for 5 minutes.

No air comes out from the

bleeder screw established to the

torque transfer differential.

3

Oil level

check

Oil level

check

Operate the direction valve to left

and right for 20 seconds.

Oil level of reservoir tank is

adequate.

4

Motor drive

Electric pump

operation

Operate the electric pump for 3

seconds.

Operating sound of the electric

pump can be heard.

5

ACD

operation

check

ACD

operation

check

Operate the proportioning valve

<ACD>, and supply the maximum

hydraulic pressure to the

multiplate clutch.

The tight corner braking

phenomenon occurs.

6

AYC

operation

check (left)

Clutch

operation

check <left

side>

Operate the direction valve, and

supply the maximum hydraulic

pressure to the left clutch.

With the wheels lifted, a speed

difference is generated between

left and right rear wheels.

7

AYC

operation

check (right)

Clutch

operation

check <right

side>

Operate the direction valve, and

supply the maximum hydraulic

pressure to the right clutch.

With the wheels lifted, a speed

difference is generated between

left and right rear wheels.