Mitsubishi Evolution X. Manual - part 262

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-25

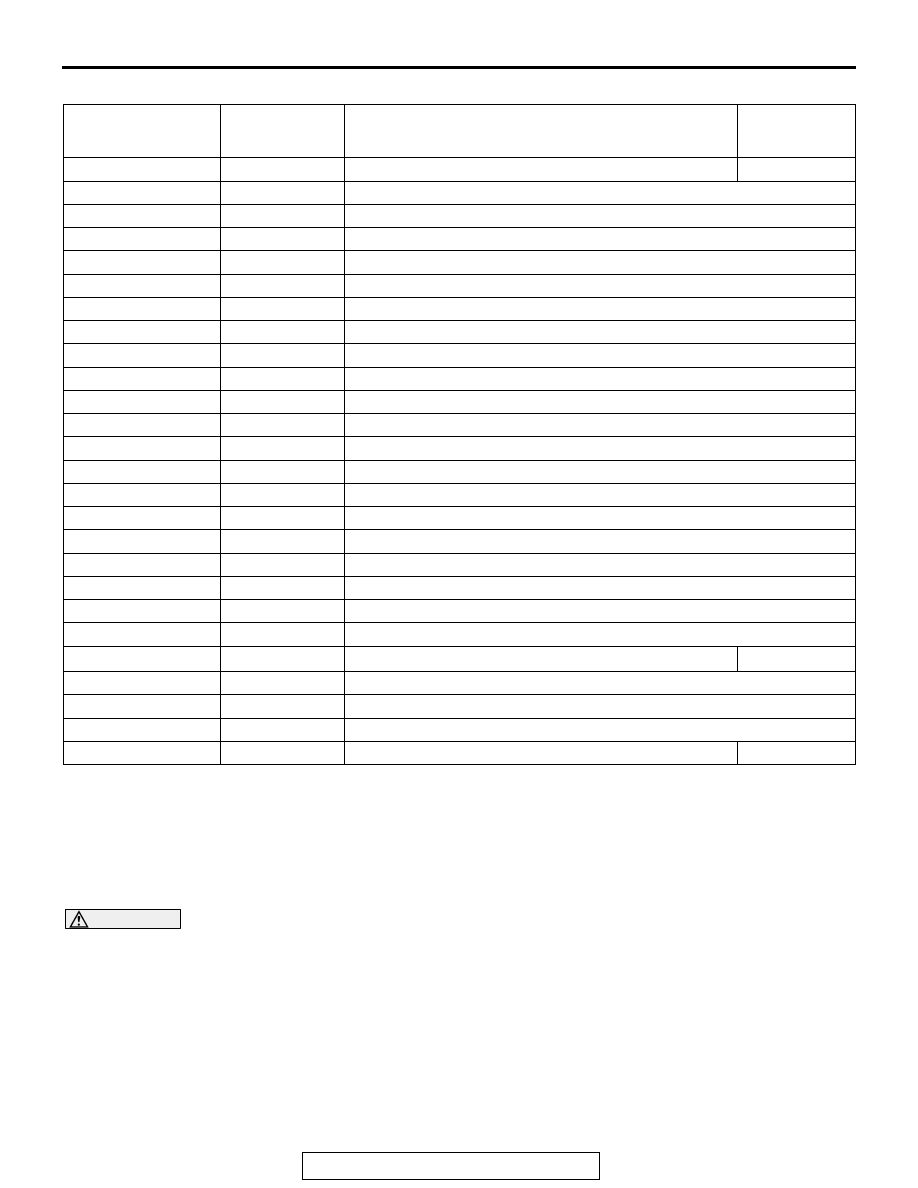

Freeze Frame Data for General Scan Tool

OBD- II DRIVE CYCLE

All kinds of diagnostic trouble codes (DTCs) can be monitored by carrying out a short drive according to the

following 23 drive cycle patterns. In other words, doing such a drive regenerates any kind of trouble which

involves illuminating the Malfunction Indicator Lamp (SERVICE ENGINE SOON or Check Engine Lamp) and

verifies the repair procedure has been eliminated [the trouble the Malfunction Indicator Lamp (SERVICE

ENGINE SOON or Check Engine Lamp) is no longer illuminated].

CAUTION

Two technicians should always be in the vehicle when carrying out a test.

NOTE: Check that the diagnosis trouble code (DTC) is not output before driving the OBD-II drive cycle. Erase

the DTC if it has been output.

NOTE: Drive cycle patterns are not established for Vehicle speed signal monitor (DTC P0500), Power steer-

ing pressure switch monitor (P0551), and Fuel level sensor monitor (DTC P0461, P2066). Please reference

the M.U.T. data list to judge whether these monitor items are normal.

COMMON EXAMPLE of

GENERAL SCAN

TOOL DISPLAY

PRAMETER

IDENTIFICATION

(PID)

DESCRIPTION

UNIT or STATE

DTCFRZF

02

DTC that caused required freeze frame data storage Pxxxx, Uxxxx

FUELSYS 1

03

See M.U.T.-III Item No. C0

LOAD_PCT

04

See M.U.T.-III Item No. C2

ECT

05

See M.U.T.-III Item No. C3

SHRTFT 1

06

See M.U.T.-III Item No. C4

LONGFT 1

07

See M.U.T.-III Item No. C6

MAP

0B

See M.U.T.-III Item No. CC

RPM

0C

See M.U.T.-III Item No. CD

VSS

0D

See M.U.T.-III Item No. CE

SPARKADV

0E

See M.U.T.-III Item No. CF

IAT

0F

See M.U.T.-III Item No. D0

MAF

10

See M.U.T.-III Item No. AA

TP

11

See M.U.T.-III Item No. AB

RUNTM

1F

See M.U.T.-III Item No. D1

EVAP_PCT

2E

See M.U.T.-III Item No. D6

FLI

2F

See M.U.T.-III Item No. D7

BARO

33

See M.U.T.-III Item No. BB

VPWR

42

See M.U.T.-III Item No. D8

LOAD_ABS

43

See M.U.T.-III Item No. D9

EQ_RAT

44

See M.U.T.-III Item No. DA

TP_R

45

See M.U.T.-III Item No. BC

AAT

46

Ambient air temperature

° C (° F)

TP_B

47

See M.U.T.-III Item No. BD

APP_D

49

See M.U.T.-III Item No. BE

APP_E

4A

See M.U.T.-III Item No. BF

TAC_PCT

4C

Command Throttle Actuator Control

%