Mitsubishi Evolution X. Manual - part 186

TIMING CHAIN

TSB Revision

ENGINE MECHANICAL

11A-75

INSTALLATION SERVICE POINTS

.

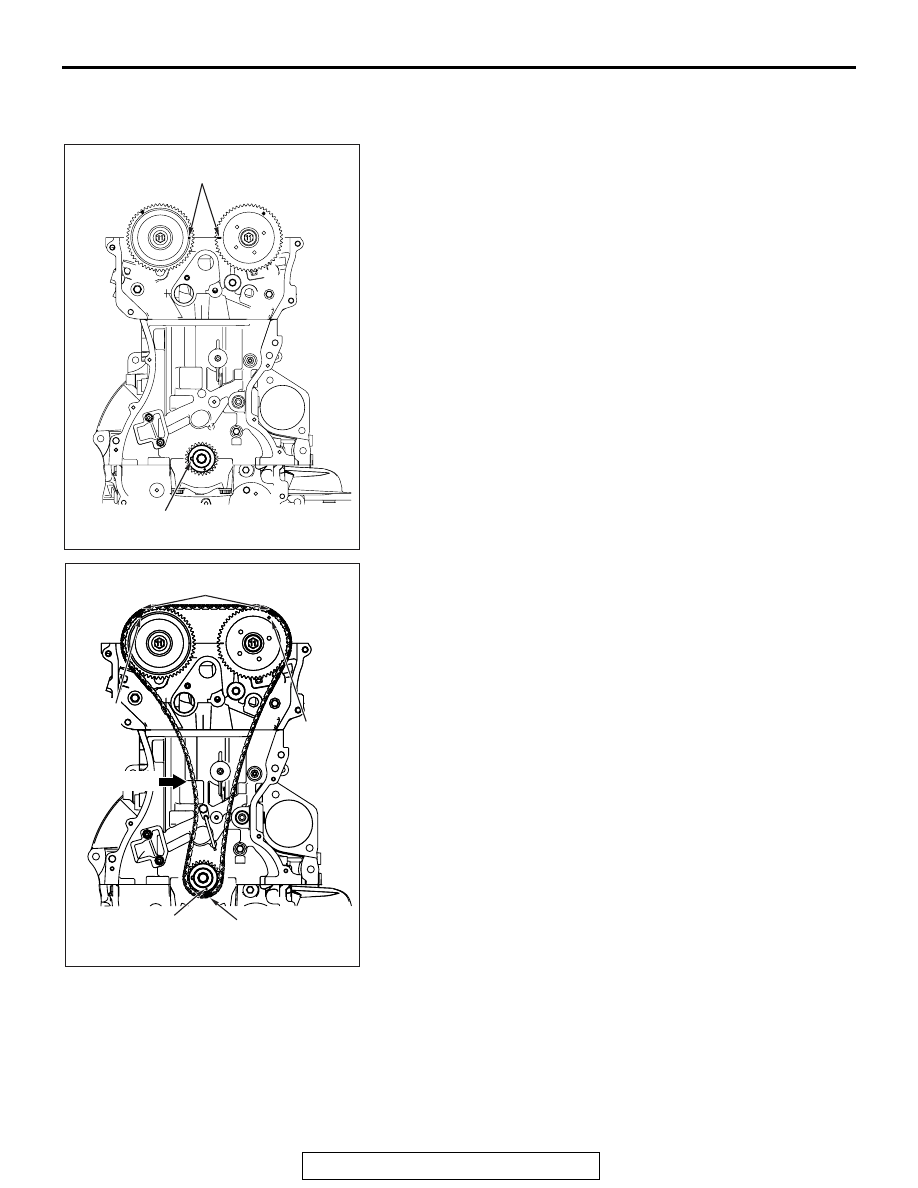

>>A<< TIMING CHAIN INSTALLATION

1. Set the timing marks of the camshaft sprockets and the

crankshaft sprocket as shown in the figure.

2. Align each sprocket timing chain mating mark with the link

plate (blue) of timing chain to avoid slack of the timing chain

tension side, and install the timing chain to the sprockets.

.

AC710641

AB

Camshaft sprocket

timing marks

Crankshaft sprocket

timing mark

AC506772

AP

Tension side

Link plates (blue)

Link plate (blue)

Mating

mark

Mating

mark

Mating mark