Mitsubishi Evolution X. Manual - part 173

CRANKSHAFT PULLEY

TSB Revision

ENGINE MECHANICAL

11A-23

INSTALLATION SERVICE POINTS

.

>>A<< CRANKSHAFT PULLEY/CRANKSHAFT

PULLEY WASHER/CRANKSHAFT PULLEY CEN-

TER BOLT INSTALLATION

1. Wipe off the dirt on the crankshaft and the crankshaft pulley

as shown in the figure using a rag.

2. Wipe off the dirt on the crankshaft sprocket, the crankshaft

and the crankshaft pulley as shown in the figure using a rag,

and then degrease them.

NOTE: Degrease them to prevent drop in the friction coeffi-

cient of the pressed area, which is caused by oil adhesion.

3. Install the crankshaft pulley.

4. Wipe off the dirt on the crankshaft pulley washer and the

crankshaft pulley center bolt as shown in the figure using a

rag.

5. Apply an adequate and minimum amount of engine oil to the

threads of the crankshaft pulley center bolt and the lower

area of the flange.

6. Hold the crankshaft pulley with special tools MB990767 and

MD998719 in the same manner as removal.

7. Tighten the crankshaft pulley center bolt according to the

following procedure.

(1) Tighten the crankshaft pulley center bolt to the specified

torque 250 N

⋅ m (184 ft-lb).

(2) Loosen the crankshaft pulley center bolt fully.

(3) Tighten the crankshaft pulley center bolt to the specified

torque 110 N

⋅ m (81 ft-lb).

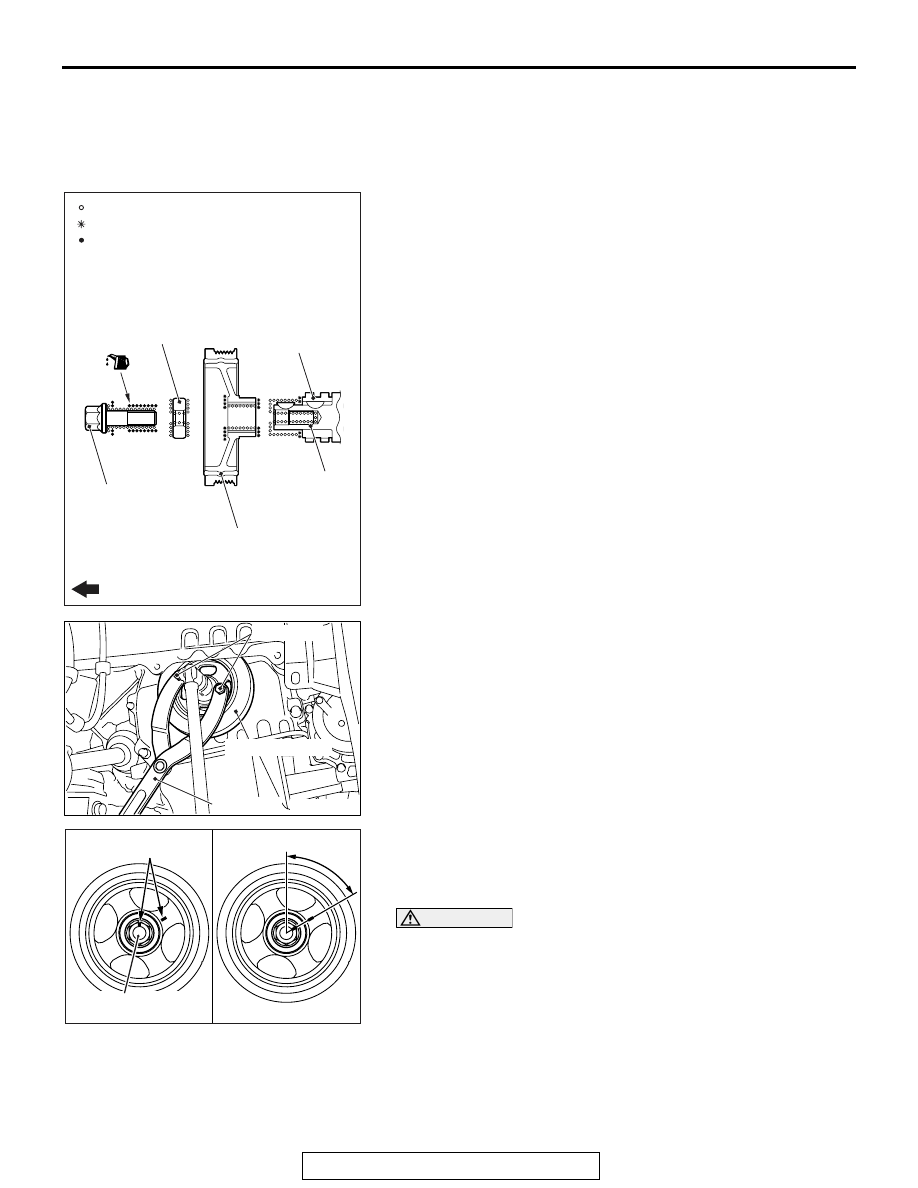

(4) As shown in the illustration "A," apply the paint mark to

the crankshaft pulley on the extended line of the corner

adjacent to the one of the crankshaft pulley center bolt

corners.

CAUTION

• When the tightening angle is smaller than the specified

tightening angle, the appropriate tightening capacity

cannot be secured.

• When the tightening angle is larger than the specified

tightening angle, remove the bolt to start from the

beginning again according to the procedure.

(5) Tighten the crankshaft pulley center bolt by 60

° once

more. Make sure the paint mark of crankshaft pulley

center bolt is aligned with the paint mark of crankshaft

pulley as shown in the illustration "B."

.

AC705007

AC

: Wipe clean with a rag.

: Wipe clean with a rag and degrease.

: Apply a small amount of engine oil.

Crankshaft

pulley center bolt

Crankshaft

pulley washer

Crankshaft

pulley

Crankshaft

Crankshaft

sprocket

Engine front

AC506738

AC

MB990767

MD998719

Crankshaft pulley

AC710640AB

A

B

60˚

Paint mark

Crankshaft pulley

center bolt