Mitsubishi Evolution X. Manual - part 171

ON-VEHICLE SERVICE

TSB Revision

ENGINE MECHANICAL

11A-15

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

11.Disconnect scan tool MB991958 from the data link

connector.

COMPRESSION PRESSURE CHECK

M1111002602278

Required Special Tool:

MB991958: Scan Tool (M.U.T.-III Sub Assembly)

• MB991824: V.C.I.

• MB991827: M.U.T.-III USB Cable

• MB991910: M.U.T.-III Main Harness A

1. Before inspection, check that the engine oil, starter and

battery are normal. Also, set the vehicle in the following

condition:

• Engine coolant temperature: 80 − 95° C (176 − 203° F)

• Lights and all accessories: OFF

• Transaxle: Neutral (P range on vehicles with TC-SST)

NOTE: On vehicles for Canada, the headlight, taillight, etc.

remain lit even when the lighting switch is in "OFF" position

but this is no problem for checks.

2. Remove all of the ignition coils and spark plugs.

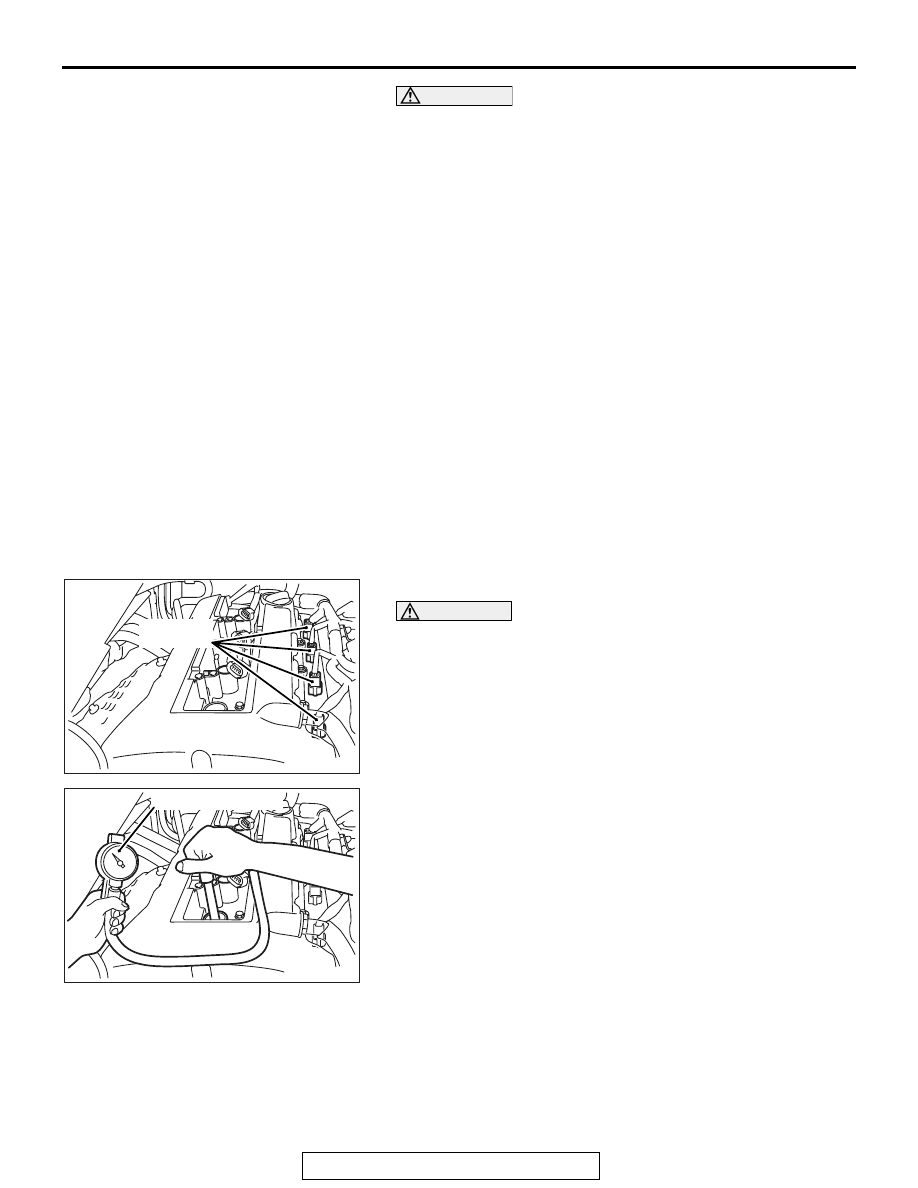

3. Disconnect the all of the injector connectors.

WARNING

Keep your distance from the spark plug hole when

cranking. Oil, fuel, etc., may spray out from the spark

plug hole and may cause serious injury.

4. Cover the spark plug hole with a shop towel etc., after the

engine has been cranked, check that no foreign material is

adhering to the shop towel.

5. Set compression gauge to one of the spark plug holes.

6. Crank the engine with the throttle valve fully open and

measure the compression pressure.

Standard value (at engine speed of 200 r/min): 1,090

kPa (158 psi)

Limit (at engine speed of 200 r/min): Minimum 650

kPa (95 psi)

7. Measure the compression pressure for all the cylinders, and

check that the pressure differences of the cylinders are

below the limit.

Limit: Maximum 100 kPa (14 psi)

8. If there is a cylinder with compression or a compression

difference that is outside the limit, pour a small amount of

engine oil through the spark plug hole, and repeat the

operations in steps from 5 to 7.

AK502603AE

Injector

connectors

AK502604AE

Compression gauge