Mitsubishi Evolution X. Manual - part 144

MANUAL TRANSAXLE

TSB Revision

MANUAL TRANSAXLE

22A-3

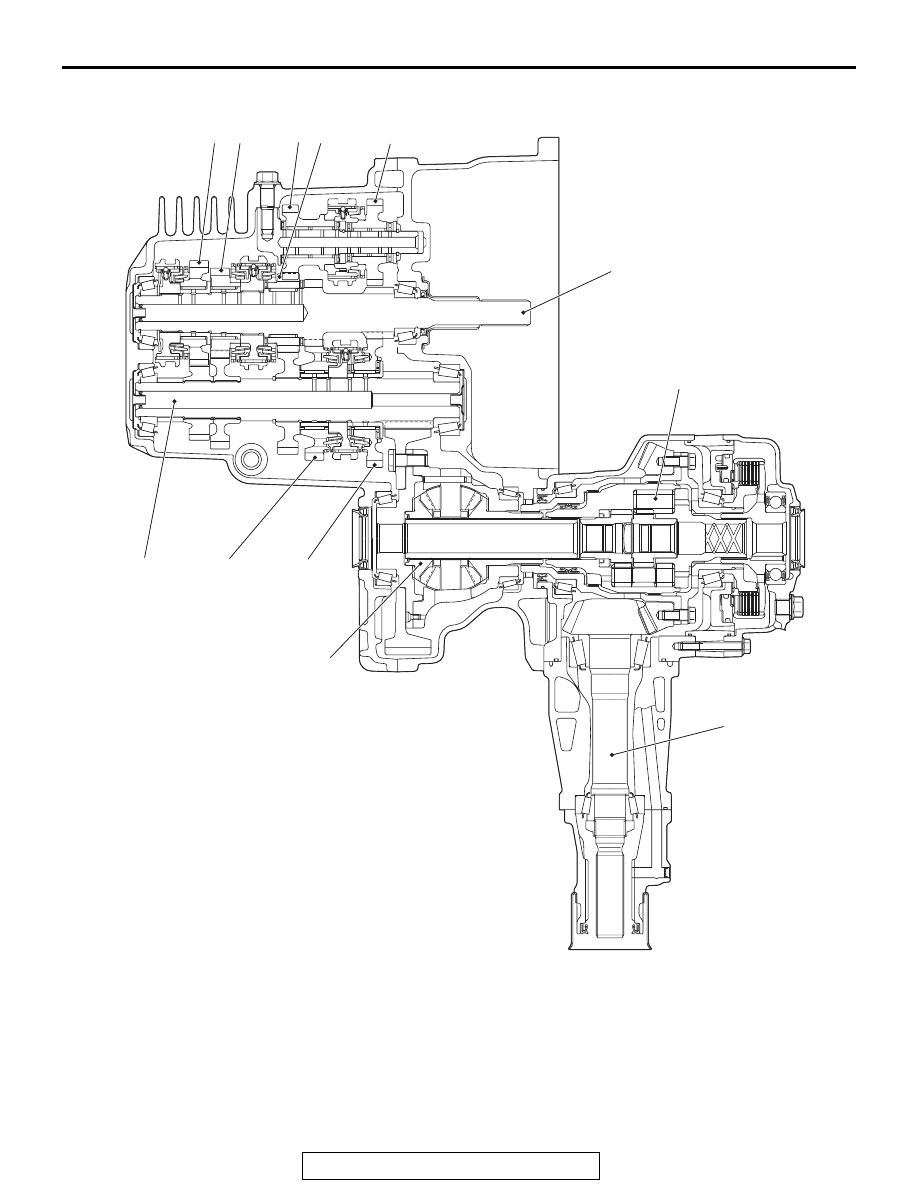

SECTIONAL VIEW

AC705183 AD

1 2

3 4

5

6

7

8

9

10

11

12

1. 5th speed gear

2. 4th speed gear

3. Rev idler gear B

4. 3rd speed gear

5. Rev idler gear A

6. Input shaft

7. Front differential (Helical gear type)

8. Hypoid pinion

9. Center differential

10. 1st speed gear

11. 2nd speed gear

12. Output shaft