Mitsubishi Evolution X. Manual - part 126

FUEL INJECTION CONTROL

TSB Revision

MULTIPORT FUEL SYSTEM (MFI)

13A-33

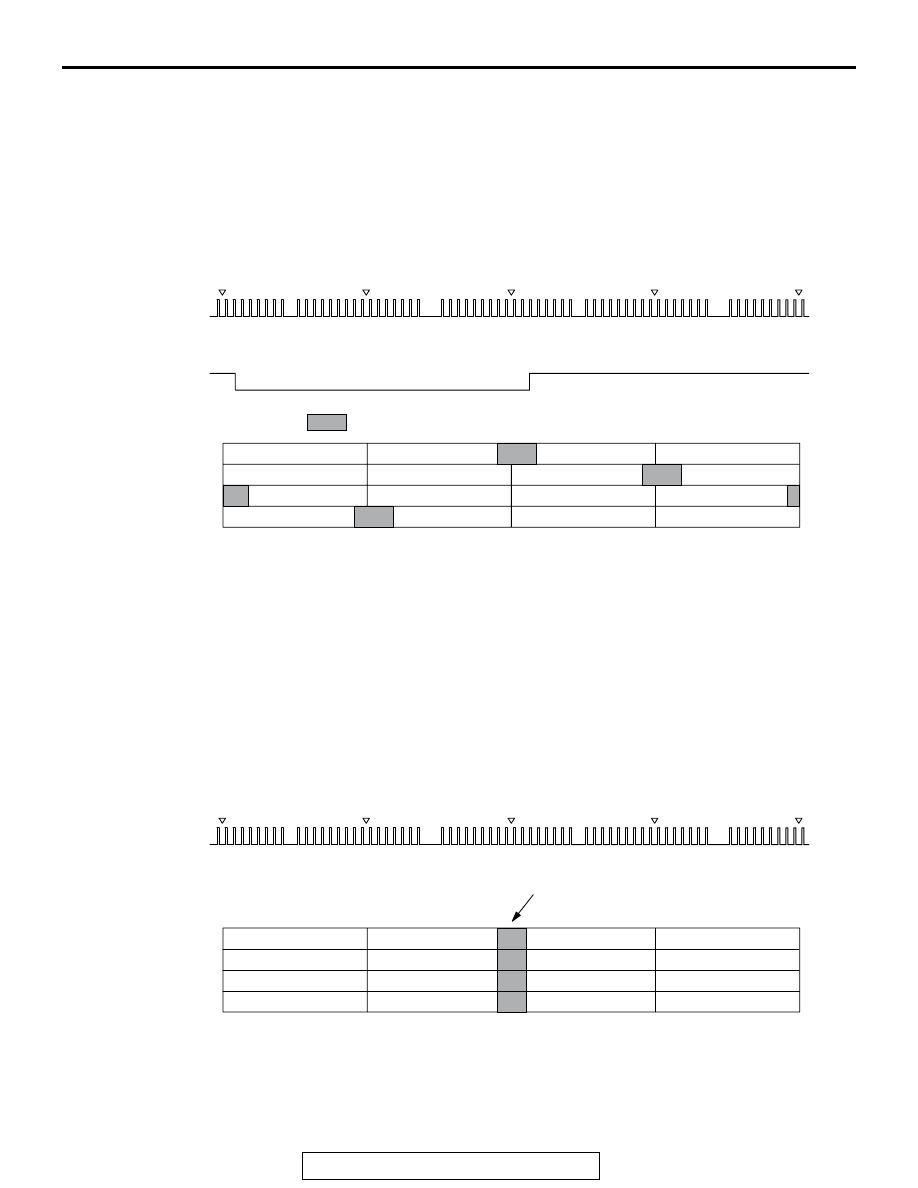

1. INJECTOR ACTUATION (FUEL INJECTION)

TIMING

Injector drive time in case of multiport fuel injection (MFI) is

controlled as follows according to driving conditions.

Fuel Injection During Cranking and Normal Operation

Fuel injection to each cylinder is done by driving the injector at

optimum timing while it is in exhaust process based on the

crankshaft position sensor signal. ECM compares the crank-

shaft position sensor output pulse signal and intake camshaft

position sensor output pulse signal to identify the cylinder.

Using this as a base, it performs sequential injection in the

sequence of cylinders 1, 3, 4, 2.

Additional Fuel Injection During Acceleration

In addition to the synchronizing fuel injection with crankshaft

position sensor signal during acceleration, the volume of fuel is

injected according to the extent of the acceleration.

AK703691

<No. 2 TDC>

H

L

H

L

<No. 1 TDC>

<No. 3 TDC>

<No. 4 TDC>

<No. 2 TDC>

AC

Crankshaft

position

sensor

signal

Intake

camshaft

position

sensor

signal

Cylinder stroke

No. 1 cylinder

No. 2 cylinder

No. 3 cylinder

No. 4 cylinder

Combustion

Intake

Exhaust

Combustion

Exhaust

Compression

: Fuel injection

Intake

Exhaust

Compression

Combustion

Intake

Compression

Intake

Exhaust

Combustion

Compression

AK703786

<No. 2 TDC>

H

L

<No. 1 TDC>

<No. 3 TDC>

<No. 4 TDC>

<No. 2 TDC>

AC

Crankshaft

position

sensor

signal

Cylinder stroke

No. 1 cylinder

No. 2 cylinder

No. 3 cylinder

No. 4 cylinder

Combustion

Intake

Exhaust

Combustion

Exhaust

Increase injection for acceleration

Compression

Intake

Exhaust

Compression

Combustion

Intake

Compression

Intake

Exhaust

Combustion

Compression