Mitsubishi Evolution X. Manual - part 124

ACTUATOR

TSB Revision

MULTIPORT FUEL SYSTEM (MFI)

13A-25

ACTUATOR

M2132002000591

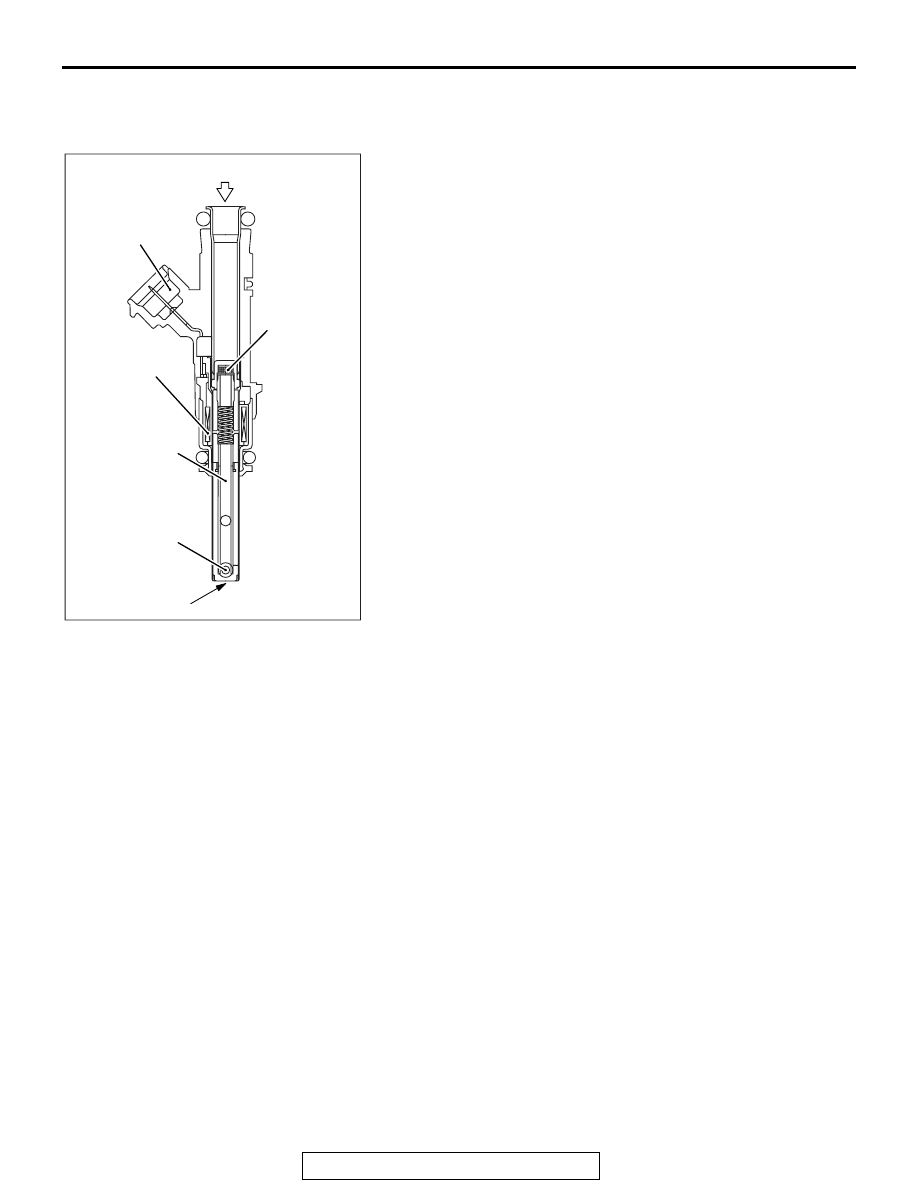

INJECTOR

An injector is an injection nozzle with the electromagnetic valve

that injects fuel based on the injection signal sent by ECM. 1

injector is installed in the intake manifold of each cylinder and

fixed to the fuel rail. When electricity flows through the solenoid

coil, the plunger gets sucked in. The ball valve is integrated

with the plunger, and gets pulled together with the plunger till

the fully open position so that the injection hole is fully open

and the fuel gets injected.

AK700570

Fuel

Plate

Ball valve

Plunger

Solenoid coil

Connector

Filter

AD