Mitsubishi Evolution X. Manual - part 46

ALUMINUM PANEL

TSB Revision

WELDED PANEL REPLACEMENT

3-54

CAUTION

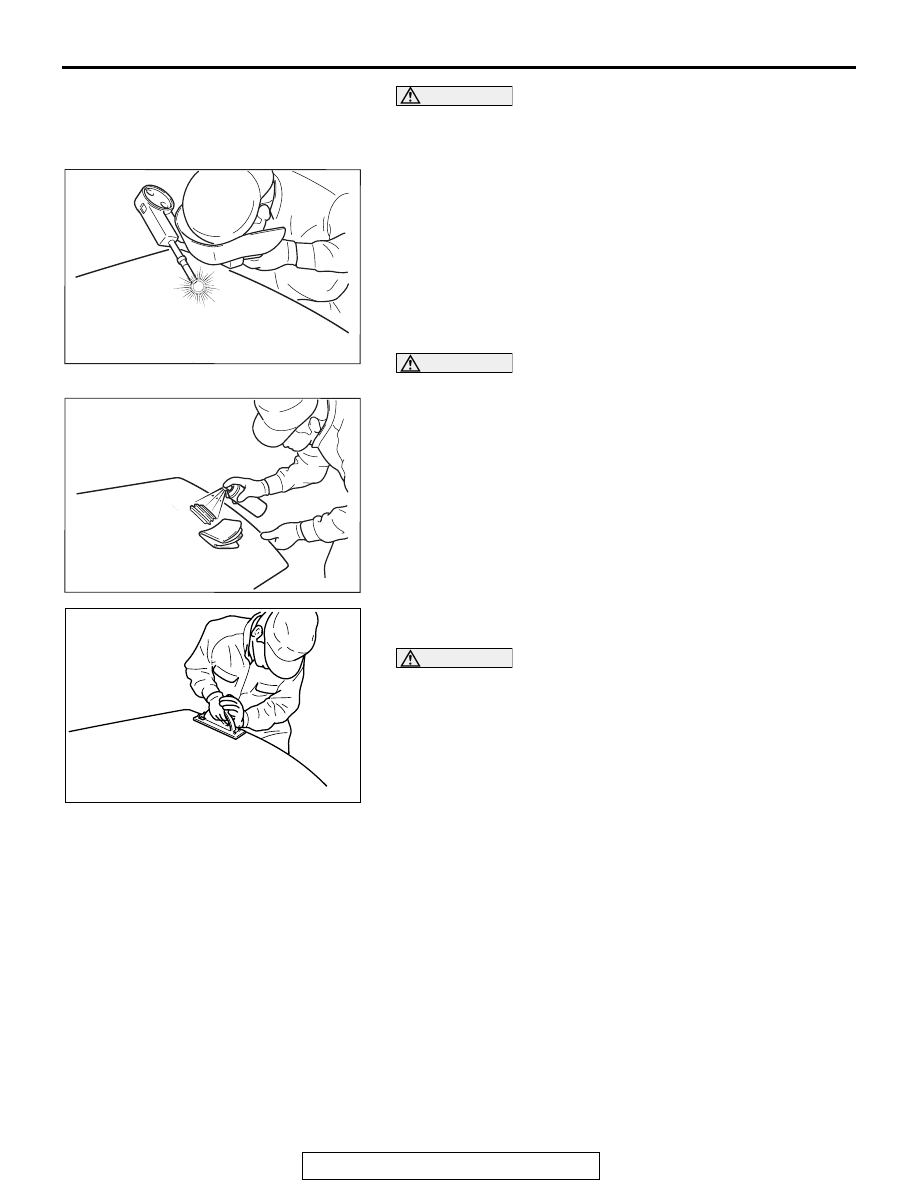

To minimize distortion and meltdown, divide a welding

area into several short segments, and weld one segment at

a time.

2. Welding: Use an aluminum dedicated welding machine or a

shared welding machine for aluminum and steel sheet for

the operation.

Wire diameter: 0.8 or 1.0 mm (0.031 or 0.039 inch)

(1) Degrease the welding area by white gasoline or the like.

(2) Remove the oxide coat from the welding area, including

its back, with a stainless steel wire brush just before

welding. Welding shall be started as soon as the oxide

coat is removed.

CAUTION

Do not over-grind the base of the panel.

3. Refinish the welding area by a #100-grit disk sander, and

then check for any faulty welding by the visible dye

penetrate testing.

4. Check for distortion: Grind the surface with #80 to #120-grit

sandpaper and then check for distortion.

CAUTION

• The heating temperature should be approximately

250

°C (482°F).

• Pay particular attention to heating, because it is melted

without discolouration by heat.

• Cover the vicinity of the area to be heated with a wet

rag or the like to prevent temperature rise and influence

of heat (distortion).

• Do not use a draw hammer for steel sheets because it

may cause the panel crack.

5. Remove distortion by the draw correction procedure with a

flattening hammer and a burner.

AB202118 AB

AB202117AB

AB202113

AB