Mitsubishi Evolution X. Manual - part 4

WELDING

TSB Revision

BASE OF BODY REPAIR

9-13

GAS WELDING

Gas welding is a method in which a high temperature flame is

used to melt both a welding rod and the base metal (panels) to

make a fused joint. Oxy-acetylene is the most common type of

gas welding. However, because of the extremely high tempera-

ture of the fused joint, the strength of the steel plate deterio-

rates, and there is a higher possibility of warping. This method,

therefore, is not very suitable for body repair.

.

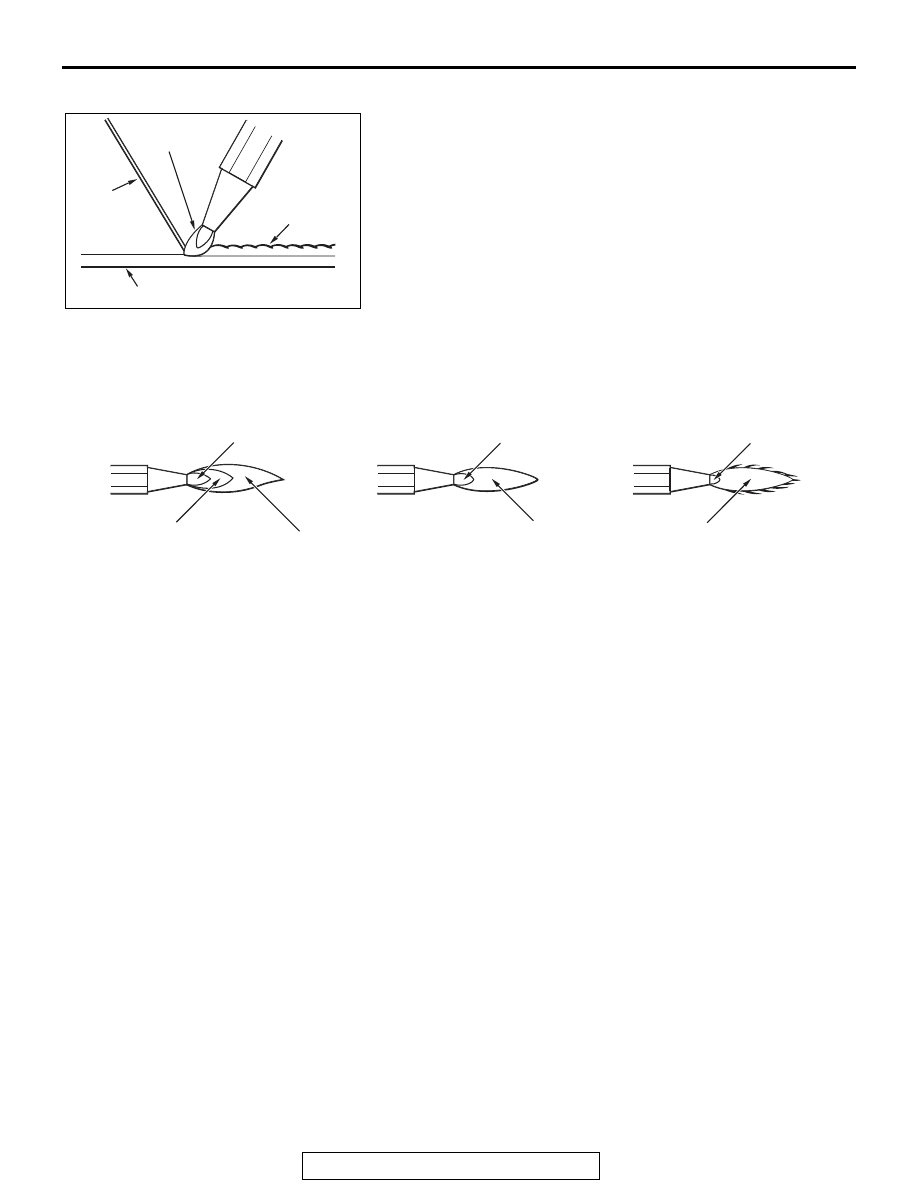

The flame in gas welding can be classified according

to the ratio of acetylene and oxygen.

1. Carburizing flame (acetylene-rich flame)

This flame has an excess of acetylene or a defi-

ciency of oxygen. The incomplete combustion

gives off a black smoke, and two flame cores can

be seen inside the deformed yellow flame. The

flame itself is large, but the temperature is rela-

tively low, making this flame unsuitable for weld-

ing.

2. Standard flame (neutral-mixture flame)

This flame has approximately equal amounts of

acetylene and oxygen. The length is shorter than

that of the carburizing flame; the flame core is

rounded; and it is clear and bright.

The carbon in the acetylene is burned completely,

resulting in the maximum obtainable temperature.

This is the flame most commonly used for weld-

ing.

3. Peroxide flame (oxygen-rich flame)

This flame has an excess of oxygen or a defi-

ciency of acetylene. The flame core is shorter

and sharper, and the entire flame has a black-

ish-purplish color. The combustion is unstable,

and the flame flickers continuously.

.

Notes with regard to gas welding

1. Handle the oxygen and acetylene tanks carefully.

2. Adjust the flame in accordance with the type of

metal being welded.

3. Select a nozzle to match the work to be done.

Avoid overheating and adhesion of foreign matter

(dirt, etc.)

4. The following points are particularly important

when welding mild steel plate.

• Melt a sufficient amount of welding rod, but be

careful not to melt the base metal. Use the

same amount of welding rod on both sides.

• Use the correct amount of welding rod in

accordance with the melting point of the base

metal.

• Avoid welding over places which have been

welded before.

• In order to avoid warping, do only the amount

of tack welding that is absolutely required.

AB200049

Deposite

Base metal

Welding

rod

Oxy-acetylene

flame

AD

AB200050

Flame core

Outer flame

Acetylene cone

AE

1. Carburizing flame

Outer flame

Outer flame

Flame core

Flame core

2. Standard flame

3. Peroxide flame