Mitsubishi Evolution X. Manual - part 3

WELDING

TSB Revision

BASE OF BODY REPAIR

9-9

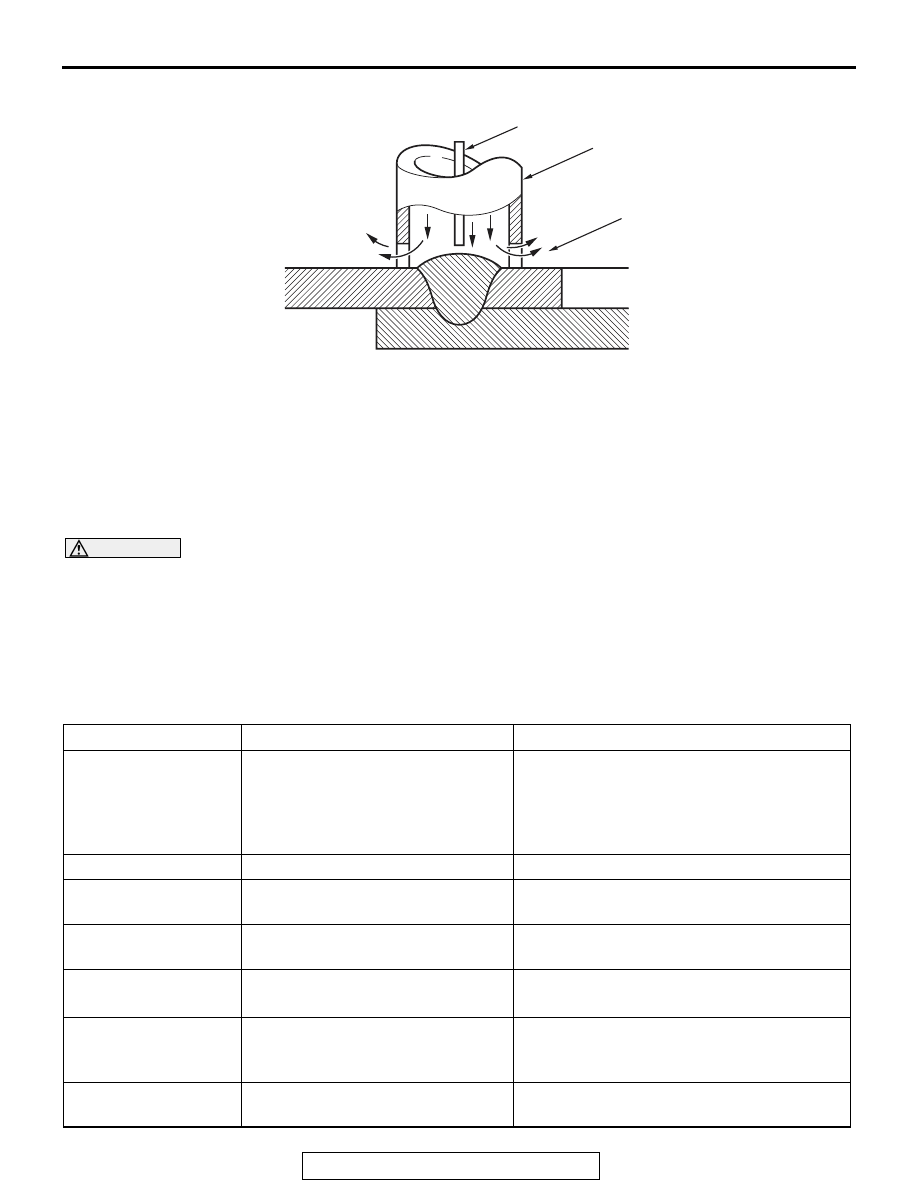

MIG SPOT WELDING

This welding method is used in areas where regular

spot welding cannot be done. The two panels are

stacked together, the tip of the torch (one designed

for use in MIG spot welding) is positioned on one

side, an arc is generated for a short time, and a par-

tial melting is done to obtain a spot weld.

.

Procedure

CAUTION

• Make sure that the area to be welded is per-

fectly clean; remove oxidation film, scales,

rust, dirt, etc.

• The two panels to be welded must be in per-

fect contact with each other.

• The number and pitch of the weld points

should be approximately the same as for the

factory welds.

1. Position the tip of the nozzle at a right angle to the

surface to be welded.

2. Being sure that the two prongs are not leaning to

either side, set them in direct contact with the

panel to the welded.

3. Welding will begin when the torch trigger is

squeezed, and will stop automatically when the

weld is complete.

.

FEATURES OF MIG SPOT WELDING

In comparison to resistance spot welding, MIG spot

welding has the following advantages and disadvan-

tages.

AB200036

Gas cup

Gas outlet

Wire

AE

Item

Mig spot welding

Electric resistance spot welding

Working

characteristics

• Light weight

• Welding possible at various

positions (no limit upon welding

positions)

• Although the torch with separate

transformer is lightweight, the torch

combined with transformer type is heavy.

• The arm must be exchanged to conform

to the weld location.

Weld time/point

Slow (0.5 second or more)

Fast (0.5 second or less)

Treatment after

welding

Necessary (grinding by grinder,

etc.)

Unnecessary

Power

High voltage, low current

(15

− 30 V, 50 − 200 A)

Low voltage, high current

(2

− 4 V, 4 − 10 kA)

Flux material

• CO

2

(carbonic acid gas)

• Weld wire

Unnecessary

Weld points/10

minutes

(rate of use)

• 25 points or less

• Arc instability and contact tip

burn if rate of use is exceeded.

• 50 − 60 points

• Welding rod deformation and transformer

overheating if rate of use is exceeded.

Distortion caused by

welding

Occurs easily

Rare