Mitsubishi Lancer Evolution X. Manual - part 623

LUBRICANTS

TSB Revision

MANUAL TRANSAXLE OVERHAUL

22B-5

FORM-IN-PLACE GASKET (FIPG)

This transaxle has several areas where the

form-in-place gasket (FIPG) is used for sealing. To

ensure that the FIPG fully serves its purpose, it is

necessary to observe some precautions when apply-

ing it. Bead size, continuity and location are of para-

mount importance.

Too thin a bead could cause leaks. Too thick a bead,

on the other hand, could be squeezed out of location,

causing blocking or narrowing of fluid passages. To

prevent leaks or blocking of passages, therefore, it is

absolutely necessary to apply the FIPG evenly with-

out a break, while observing the correct bead size.

FIPG hardens as it reacts with the moisture in the

atmospheric air, and it is usually used for sealing

metallic flange areas.

CAUTION

When re-applying liquid gasket (FIPG), be sure

that:

1. Residues of FIPG are cleared from all the ins

and outs of parts;

2. Use Mitsubishi genuine parts cleaner

(MZ100387) or equivalent to well degrease the

FIPG-applied surface.

3. FIPG is correctly applied in accordance with

FIPG Application.

.

Disassembly

Parts sealed with a FIPG can be easily removed

without need for the use of a special method. In

some cases, however, the FIPG in joints may have to

be broken by tapping parts with a mallet or similar

tool.

.

Surface Preparation

Thoroughly remove all substances deposited on the

FIPG application surface, using a gasket scraper.

Make sure that the FIPG application surfaces is flat

and smooth. Also make sure that the surface is free

from oils, greases and foreign substances. Do not fail

to remove old FIPG that may remain in the fastener

fitting holes.

.

FIPG Application

Applied FIPG bead should be of the specified size

and free of any break. FIPG can be wiped away

unless it has completely hardened. Install the mating

parts in position while the FIPG is still wet. Do not

allow FIPG to spread beyond the sealing areas dur-

ing installation. Avoid operating the transaxle or let-

ting oils or water come in contact with the sealed

area before a time sufficient for FIPG to harden

(approximately one hour) has passed.

FIPG application method may vary from location to

location. Follow the instruction for each particular

case described later in this manual.

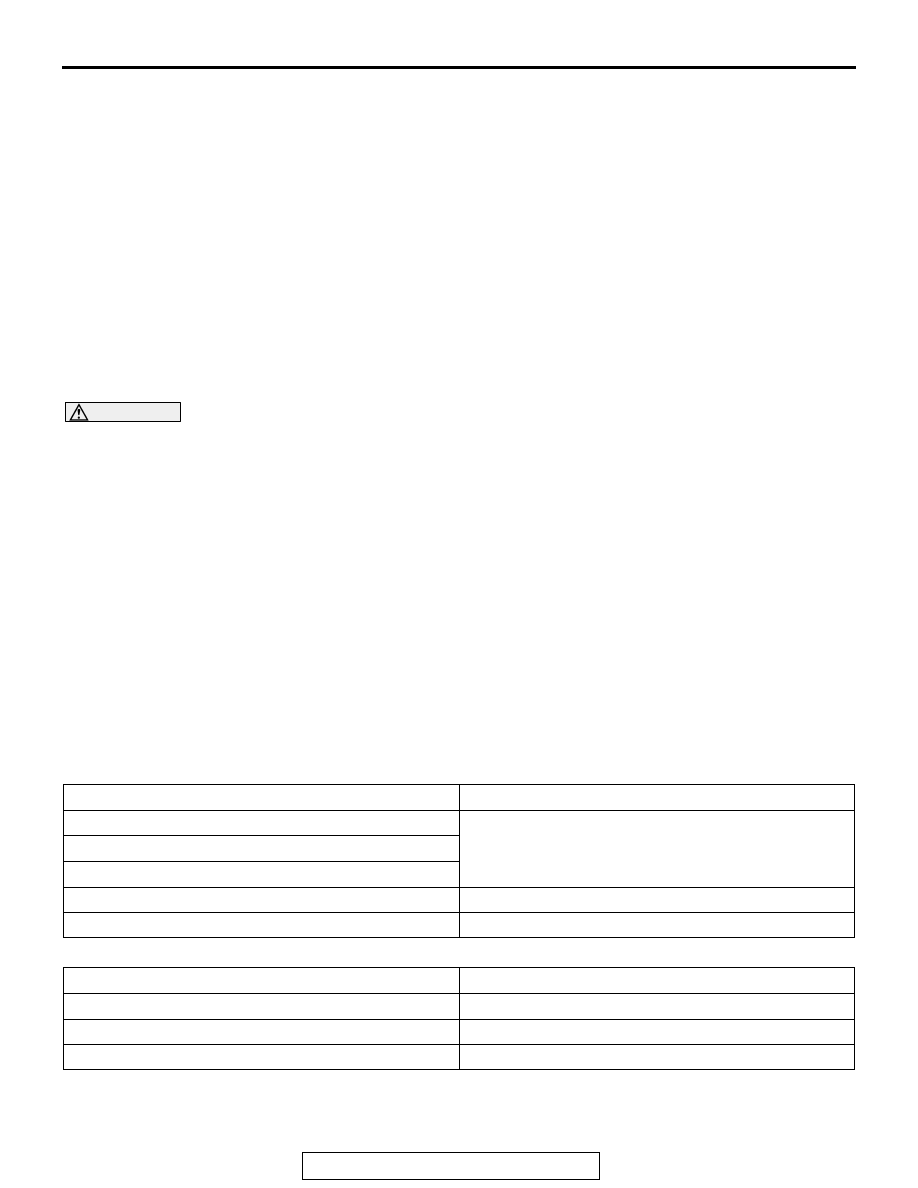

LUBRICANTS

M1222000400819

TRANSAXLE

TRANSFER

Item

Specified sealant

Transaxle oil

Mitsubishi Genuine DiaQueen NEW MULTI GEAR

OIL API classification GL-3, SAE 75W-80

Control shaft oil seal lip gear oil

Oil seal (transaxle case)

Select lever shoe

Mitsubishi Part No. 0101011 or equivalent

Input shaft oil seal lip gear oil

Retinax A

Item

Specified lubricant

Transfer oil

Hypoid gear oil API classification GL-5, SAE90

O-ring

Mitsubishi Genuine DiaQueen ATF SPIII

Oil seal

Retinax A