Mitsubishi Lancer Evolution X. Manual - part 611

ON-VEHICLE SERVICE

TSB Revision

TWIN CLUTCH- SPORTRONIC SHIFT TRANSMISSION (TC-SST)

22C-401

KEY INTERLOCK MECHANISM CHECK

M1225008500154

1. Perform the following checks.

2. If there is a problem with above operations, install the key

interlock cable according to the procedure below. (Automatic

adjustment)

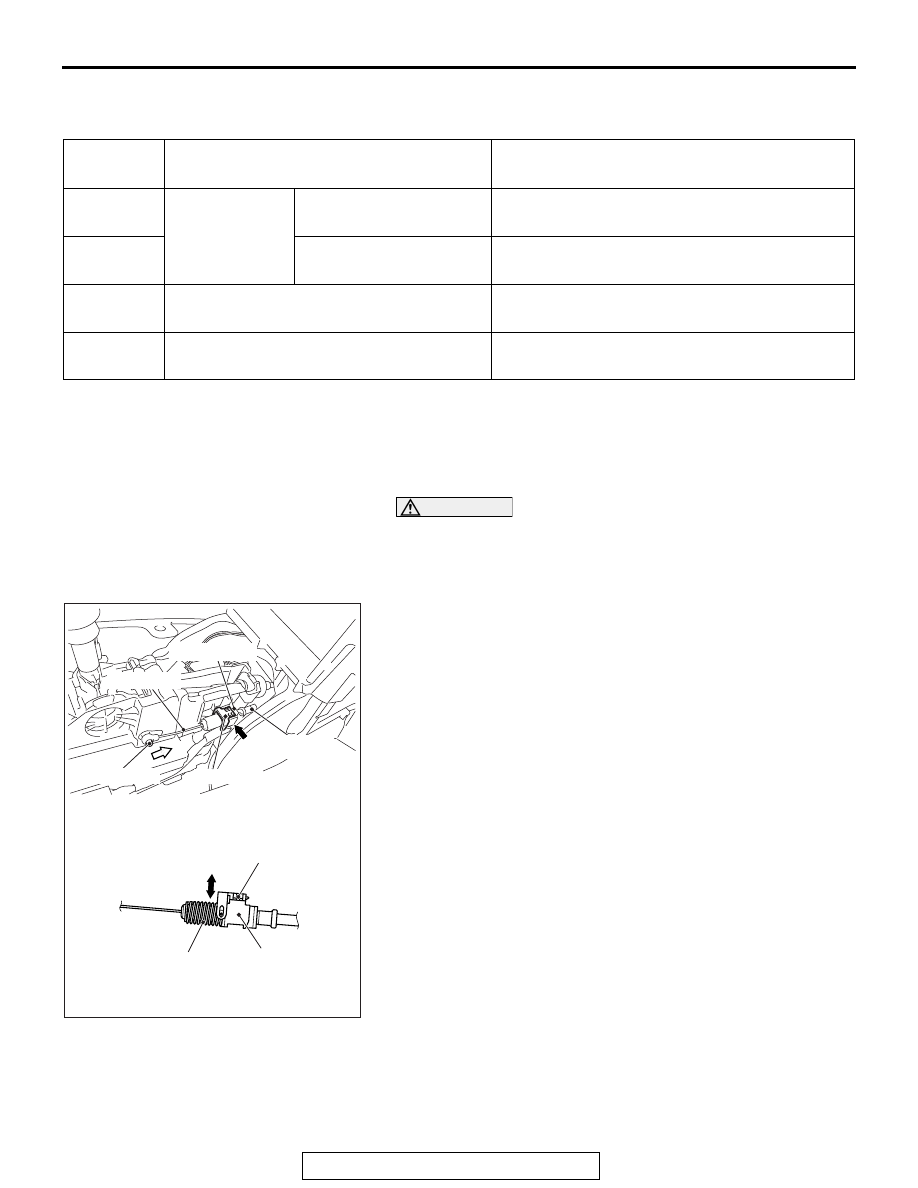

(1) Disconnect the key interlock cable connection (shift lever

side).(Refer to

CAUTION

Leave the ignition switch in the LOCK (OFF) position until

the key interlock cable installation is completed.

(2) Move the shift lever to the P position, and turn the ignition

switch to the LOCK (OFF) position.

(3) Install the tip of key interlock cable to the lock cam of shift

lever assembly, using a caution not to twist the inner

cable.

(4) Install the adjuster case with its lock guide pulled up

(unlocked).

(5) With the lock cam pin pushed in the direction B as shown

in the figure to remove the slack from the key interlock

cable, securely lower the lock guide and lock it.

NOTE: The lock position of the key interlock cable is

automatically adjusted by a spring.

Inspection

procedure

Check conditions

Items to be checked (Normal status)

1

Brake pedal:

Depressed

Ignition switch position:

LOCK (OFF) or ACC

The shift lever cannot be moved out of the P

position.

2

Ignition switch position:

ON

The shift lever can be moved from the P position

to other positions smoothly.

3

Shift lever position: Other than P

The ignition switch cannot be turned to the

LOCK (OFF) position.

4

Shift lever position: P

The ignition switch can be turned to the LOCK

(OFF) position smoothly.

AC900053

View A

Key inter

lock cable

A

Adjuster case

Inner cable

Lock guide

AC

Spring

Lock

Adjuster case

Lock guide

Unlock

B

Lock cam pin