Mitsubishi Lancer Evolution X. Manual - part 586

DIAGNOSIS <TC-SST>

TSB Revision

TWIN CLUTCH- SPORTRONIC SHIFT TRANSMISSION (TC-SST)

22C-301

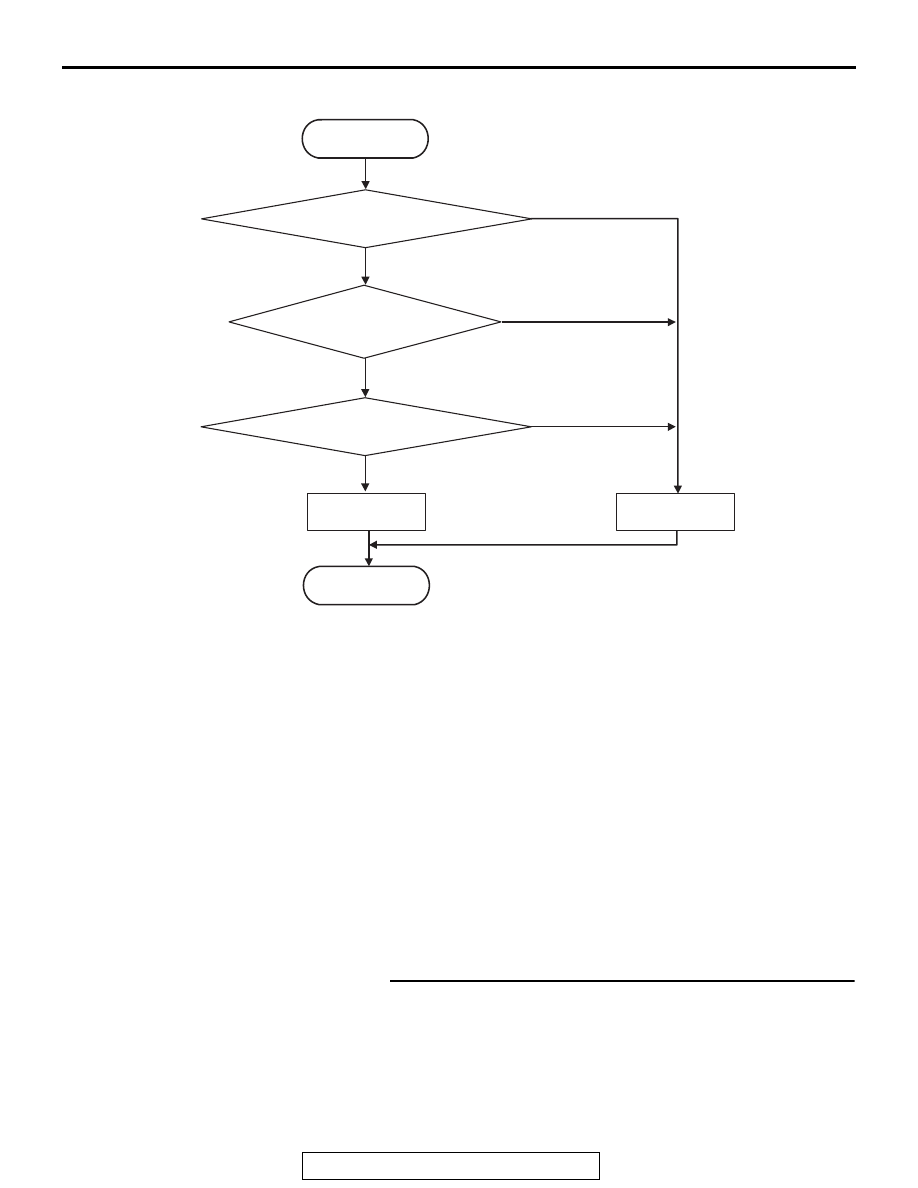

LOGIC FLOW CHARTS (Monitor Sequence)

.

DTC SET CONDITIONS

Check Conditions

• Voltage of battery: 8 V or more.

• Voltage of battery: 16.5 V or less.

• Clutch/shift pressure solenoid 2: OFF.

JUDGMENT CRITERIA

• FET (Field Effect Transistor) output: (Battery volt-

age − 2 V) or more. (160 millisecond)

.

OBD-II DRIVE CYCLE PATTERN

The FET channel output remains (Battery voltage − 2

V) or less for 160 milliseconds.

.

PROBABLE CAUSES

• Malfunction of TC-SST-ECU

• Malfunction of clutch/shift pressure solenoid 2

DIAGNOSTIC PROCEDURE

Required Special Tools:

• MB991958 Scan Tool (M.U.T.-III Sub Assembly)

• MB991824: Vehicle Communication Interface (V.C.I.)

• MB991827 M.U.T.-III USB Cable

• MB991910 M.U.T.-III Main Harness A

STEP 1. Scan tool CAN bus diagnostics

Using scan tool MB991958, diagnose the CAN bus lines.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair the CAN bus lines. (Refer to GROUP 54C −

Troubleshooting

.) After repairing the CAN

bus line, go to Step 2.

AC710659

START

No

Good

Malfunction

END

Monitoring condition met

Continuous failure

for 160 msec

No

Yes

Yes

Yes

FET* output

> Battery voltage - 2V

No

*FET : Field Effect Transistor