Mitsubishi Lancer Evolution X. Manual - part 507

ON-VEHICLE SERVICE

TSB Revision

MANUAL TRANSAXLE

22A-121

5. Rotate the steering wheel 180° or more to the right or left,

and drive the vehicle at 20 km/h or less to check that the

tight corner braking phenomenon occurs.

NOTE:

.

•

The occurrence levels of body vibration and noise

caused by the tight corner braking phenomenon will dif-

fer depending on the conditions of tire and road surface.

•

If the tight corner braking phenomenon does not occur,

the system may have an abnormality. Therefore, check

the hydraulic pressure.

HYDRAULIC PRESSURE CHECK

M1221011800089

1. Remove the rear wheel (RH), then remove the rear wheel

splash shield.(Refer to GROUP 42A − Splash shield

.)

2. Raise the vehicle.

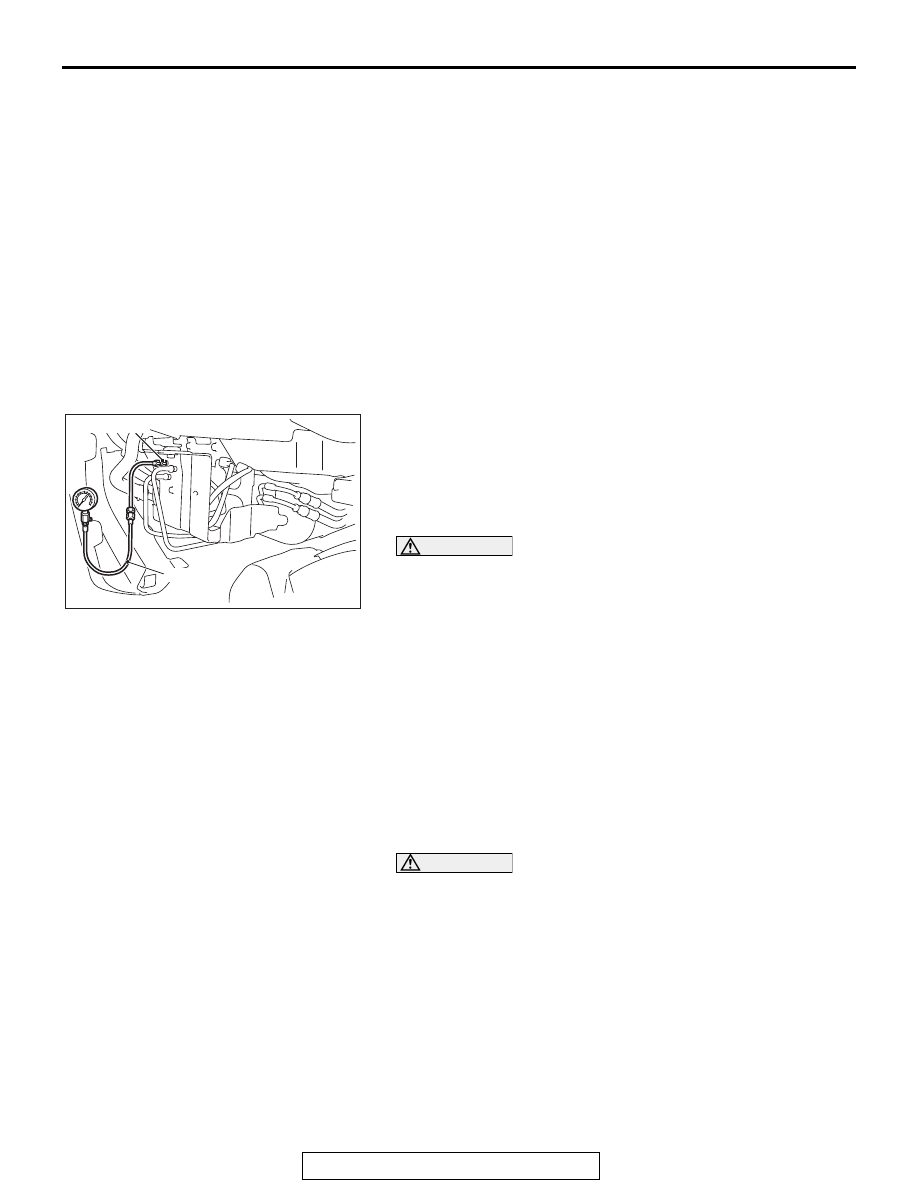

3. Disconnect the hydraulic unit from the ACD pressure tube

assembly. Then, connect the special tool below to the

hydraulic unit side.

• Hose adapter (MB991705)

• Oil pressure gauge (MD998330)

4. Bleed the system. (Refer to

CAUTION

Before connecting or disconnecting scan tool, always turn

the ignition switch to the LOCK (OFF) position.

5. Connect scan tool to the data link connector. (Refer to

.)

6. Turn the ignition switch to the "ON" position.

7. Perform the actuator test (item No. 05) of scan tool to

forcibly activate ACD.

NOTE:

.

•

The forced activation (item No. 05: ACD operation check

mode) is continued for 1 minute, then it will be canceled

automatically. Also, using the clear key on the scan tool,

the activation can be forcibly canceled.

•

When the ACD functions are stopped due to the

fail-safe, the forced activation cannot be performed.

CAUTION

During the hydraulic pressure check, fill the fluid so that

the fluid constantly remains in the oil reservoir.

8. Check that the generated hydraulic pressure of the hydraulic

unit is within the standard value.

Standard valve: 0.9 − 1.1 MPa (130 − 159 psi)

9. If the measured value exceeds the standard value, replace

the hydraulic unit.

10.After applying oil to the flare nut thread of ACD pressure

tube assembly, connect the assembly to the hydraulic unit,

then tighten to the specified torque.

Tightening torque: 26 ± 4 N⋅ m (19 ± 3 ft-lb)

11.Perform the air bleeding. (Refer to

AC707692AC

MB991705

MD998330