Mitsubishi Lancer Evolution X. Manual - part 431

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-789

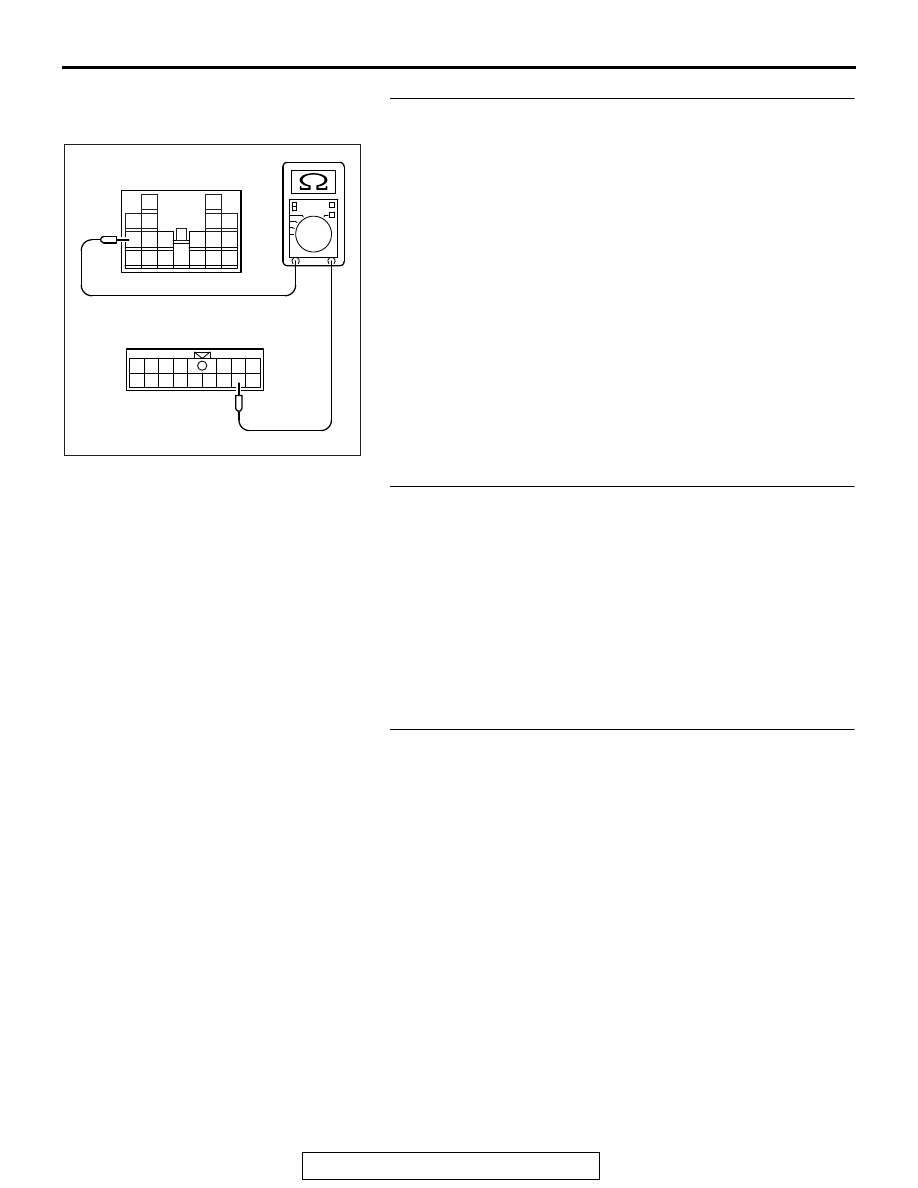

STEP 7. Check for continuity at ETACS-ECU side

connector C-304 and C-315.

(1) Disconnect the connector C-304, C-315 and measure at the

ETACS-ECU side.

(2) Measure the resistance between connector C-304 (terminal

No. 15) and connector C-315 (terminal No. 7).

• Should be less than 2 ohms

Q: Is the harness wire in good condition?

YES : Go to Step 8.

NO : Replace the ETACS-ECU. Then confirm that the

malfunction symptom is eliminated.

STEP 8. Check harness connector B-10 ECM connector for

damage.

Q: Is the connector in good condition?

YES : Repair harness wire between ETACS-ECU connector

C-304 (terminal No. 15) and ECM connector B-10

(terminal No. 105) because of open circuit or short

circuit to ground or harness damage. Then confirm

that the malfunction symptom is eliminated.

NO : Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection

. Then confirm that the

malfunction symptom is eliminated.

STEP 9. Check harness connector A-28X at starter relay

connector for damage.

Q: Is the connector in good condition?

YES : Go to Step 10.

NO : Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection

. Then confirm that the

malfunction symptom is eliminated.

1

6

4

5

9

8

10 11

13

15

14

12

16

7

2 3

7

3

8

1

4

9

13 14

16

15

10 11 12

17 18 19

2

5 6

AK704319

C-304 ETACS-ECU

side connector

C-315 ETACS-ECU

side connector

AB