Mitsubishi Lancer Evolution X. Manual - part 399

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-661

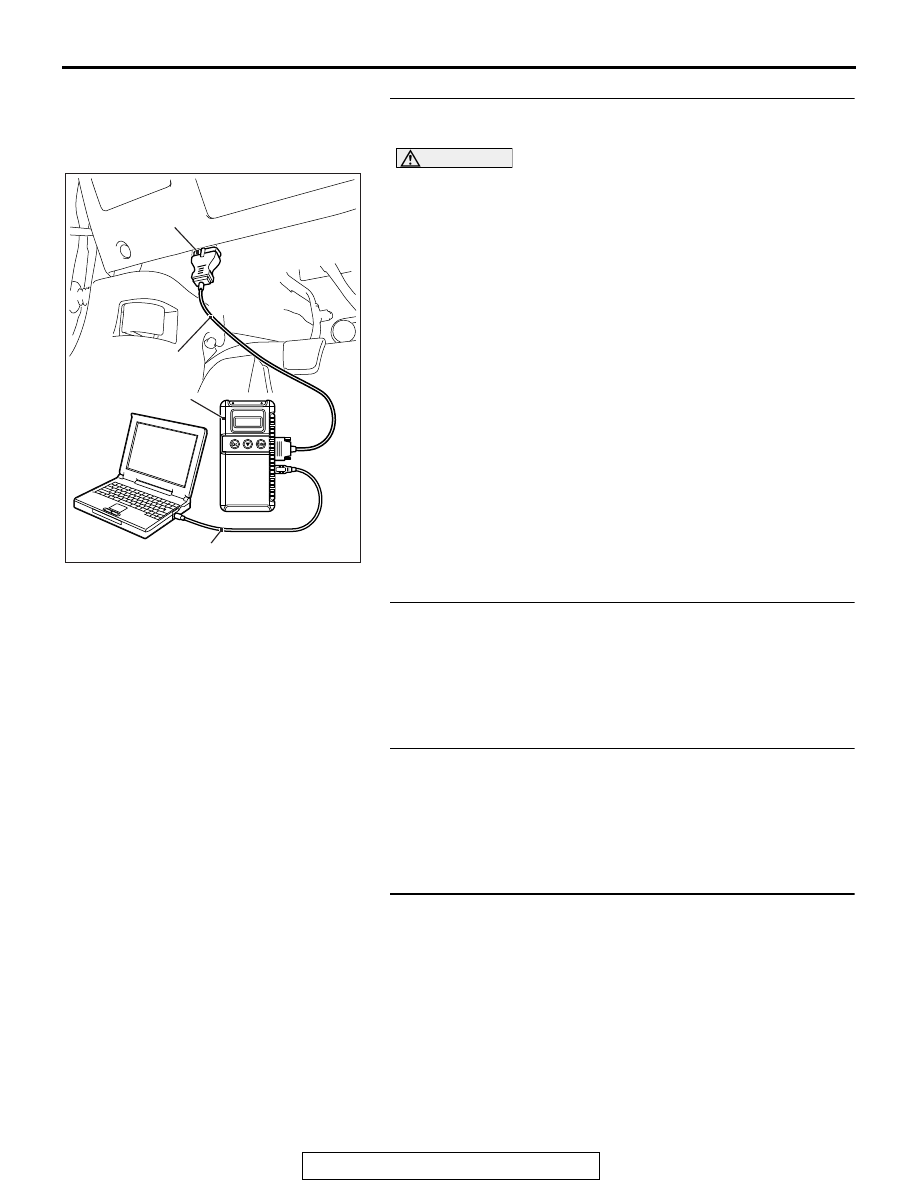

STEP 5. Using scan tool MB991958, read the diagnostic

trouble code (DTC).

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Erase the DTC.

(4) Depress the accelerator pedal fully for a few seconds.

(5) Check the DTC.

(6) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is DTC P2135 set?

YES : Replace the ECM. When the ECM is replaced,

register the ID code. Refer to GROUP 42B, ID Code

Registration Necessity Judgment Table <Vehicles

with KOS>

or GROUP 42C, ID Codes

Registration Judgment Table <Vehicles with WCM>

. Then go to Step 11.

NO : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points − How to

Cope with Intermittent Malfunctions

.

STEP 6. Check harness connector B-09 at ECM for

damage.

Q: Is the harness connector in good condition?

YES : Go to Step 7.

NO : Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection

. Then go to Step 11.

STEP 7. Check for harness damage between throttle

position sensor connector B-11 (terminal No. 5) and ECM

connector B-09 (terminal No. 12).

Q: Is the harness wire in good condition?

YES : Go to Step 8.

NO : Repair it. Then go to Step 11.

STEP 8. Check for harness damage between throttle

position sensor connector B-11 (terminal No. 4) and ECM

connector B-09 (terminal No. 10).

Q: Is the harness wire in good condition?

YES : Go to Step 9.

NO : Repair it. Then go to Step 11.

AC608435

Data link connector

MB991827

MB991824

MB991910

AB