Mitsubishi Lancer Evolution X. Manual - part 294

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-241

DTC SET CONDITIONS

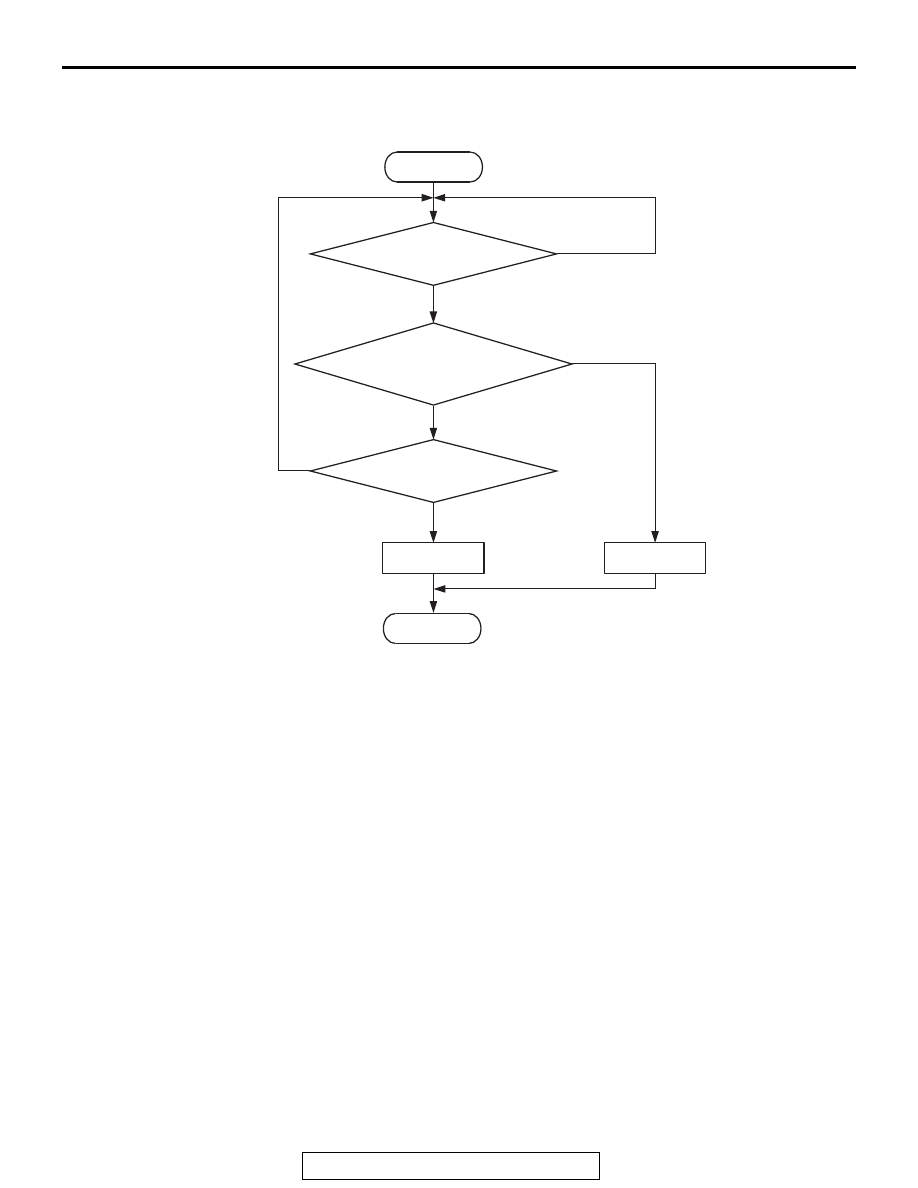

Logic Flow Chart

.

Check Conditions

• More than 300 seconds have passed since the

engine starting sequence was completed.

• Engine coolant temperature is higher than 7° C

(45° F).

• Engine speed is higher than 1,188 r/min.

• Volumetric efficiency is higher than 30 percent.

• Throttle position sensor output voltage is lower

than 3.3 volts.

• Except while fuel is being shut off.

• Monitoring time: 30 seconds.

Judgement Criterion

• Heated oxygen sensor (front) output voltage does

not get across lean/rich criteria (about 0.5 volt)

within about 30 seconds.

.

FAIL-SAFE AND BACKUP FUNCTION

• None

.

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function − OBD-II Drive Cycle −

Pattern 11

.

.

TROUBLESHOOTING HINTS (The most

likely causes for this code to be set are: )

• Heated oxygen sensor (front) deteriorated.

• Harness damage in heated oxygen sensor (front)

output line.

• Heated oxygen sensor (rear) deteriorated.

NOTE: When the heated oxygen sensor (front)

begins to deteriorate, the heated oxygen sensor

output voltage will deviate from the voltage when

the sensor was new (normally 0.5 volt at stoichio-

metric ratio). This deviation will be corrected by

the heated oxygen sensor (rear).

End

No

No

No

Malfunction

Good

30secs have passed?

AK704112

Start

Yes

Yes

Yes

Monitoring

conditions

Heated oxygen sensor

(front) output voltage

crosses lean/rich criteria?