Mitsubishi Lancer Evolution X. Manual - part 228

ON-VEHICLE SERVICE

TSB Revision

POWER STEERING

37-27

8. Turn the steering wheel all the way to the left or right; then

check whether or not the retention hydraulic pressure is the

standard value.

Standard value: 8.1 − 8.8 MPa (1,175 − 1,276 psi)

9. If not the standard value, overhaul the steering gear.

Remeasure fluid pressure.

10. Remove the special tools MB991548, MB990662 and

MB991549, and then tighten the pressure hose to the

specified torque.

Tightening torque: 57 ± 7 N⋅ m (42 ± 5 ft-lb)

11. Bleed the system (Refer to

).

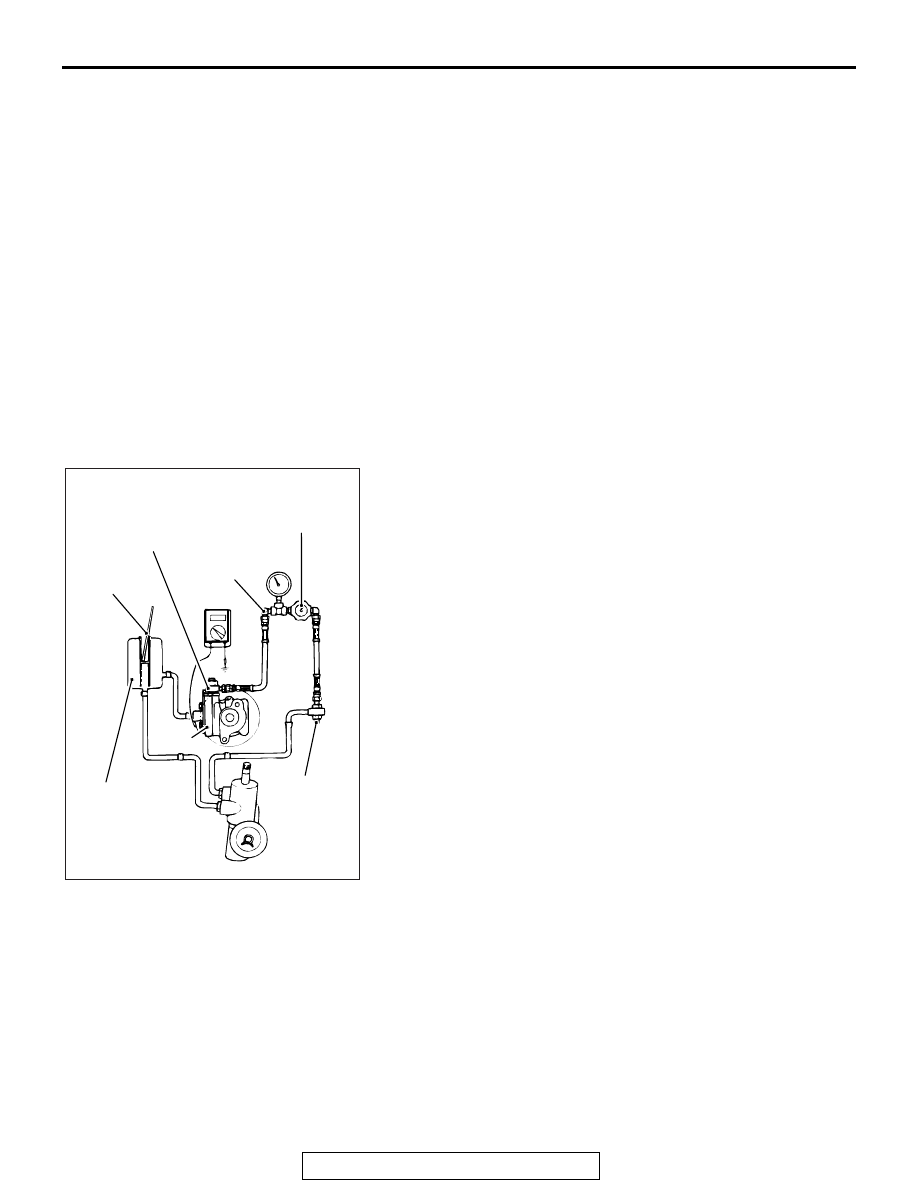

POWER STEERING PRESSURE SWITCH CHECK

M1372007200722

Required Special Tools:

• MB990662: Power Steering Oil Pressure Gauge

• MB991548: Oil Pressure Gauge Adapter A (Pump Side)

• MB991549: Oil Pressure Gauge Adapter B (Hose Side)

1. Disconnect the pressure hose from the oil pump, and then

connect the special tools MB991548, MB990662 and

MB991549.

2. Bleed air, and then turn the steering wheel several times

while the vehicle is not moving so that the temperature of

the fluid rises to approximately 50° C − 60° C (122° F −

140° F).

3. The engine should be idling.

4. Disconnect the connector for the oil pressure switch, and

place an ohmmeter at the switch.

5. Gradually close the shut-off valve of the pressure gauge and

increase the hydraulic pressure, then check whether or not

the hydraulic pressure that activates the switch is the

standard value.

2.5 − 3.0 MPa (363 − 435 psi)

6. Gradually open the shut-off valve and reduce the hydraulic

pressure; then check whether or not the hydraulic pressure

that deactivates the switch is the standard value.

1.5 − 3.0 MPa (218 − 435 psi)

7. Remove special tools MB991548, MB990662 and

MB991549, connect the pressure hose to the oil pump, and

then tighten the eye bolt to the specified torque.

Tightening torque: 57 ± 7 N⋅ m (42 ± 5 ft-lb)

8. Bleed the system. (Refer to

ACX01134 AI

Oil

pump

Shut-off

valve

Oil reservoir

Power steering

oil pressure

gauge adapter

(MB991548)

Oil pressure

gauge adapter A

(MB991548)

Oil pressure

gauge adapter

B (MB991549)

Temperature

gauge