Mitsubishi Lancer Evolution X. Manual - part 129

ON-VEHICLE SERVICE

TSB Revision

BASIC BRAKE SYSTEM

35A-21

8. While pressing the cross spring by hand, install the pin to

the brake caliper assembly.

DISK BRAKE ROTOR CHECK

M1351002900710

CAUTION

Disk brakes must be kept within the allowable

service values in order to maintain normal brake

operation.

Before turning the brake disk, the following condi-

tions should be checked.

.

BRAKE DISK THICKNESS CHECK

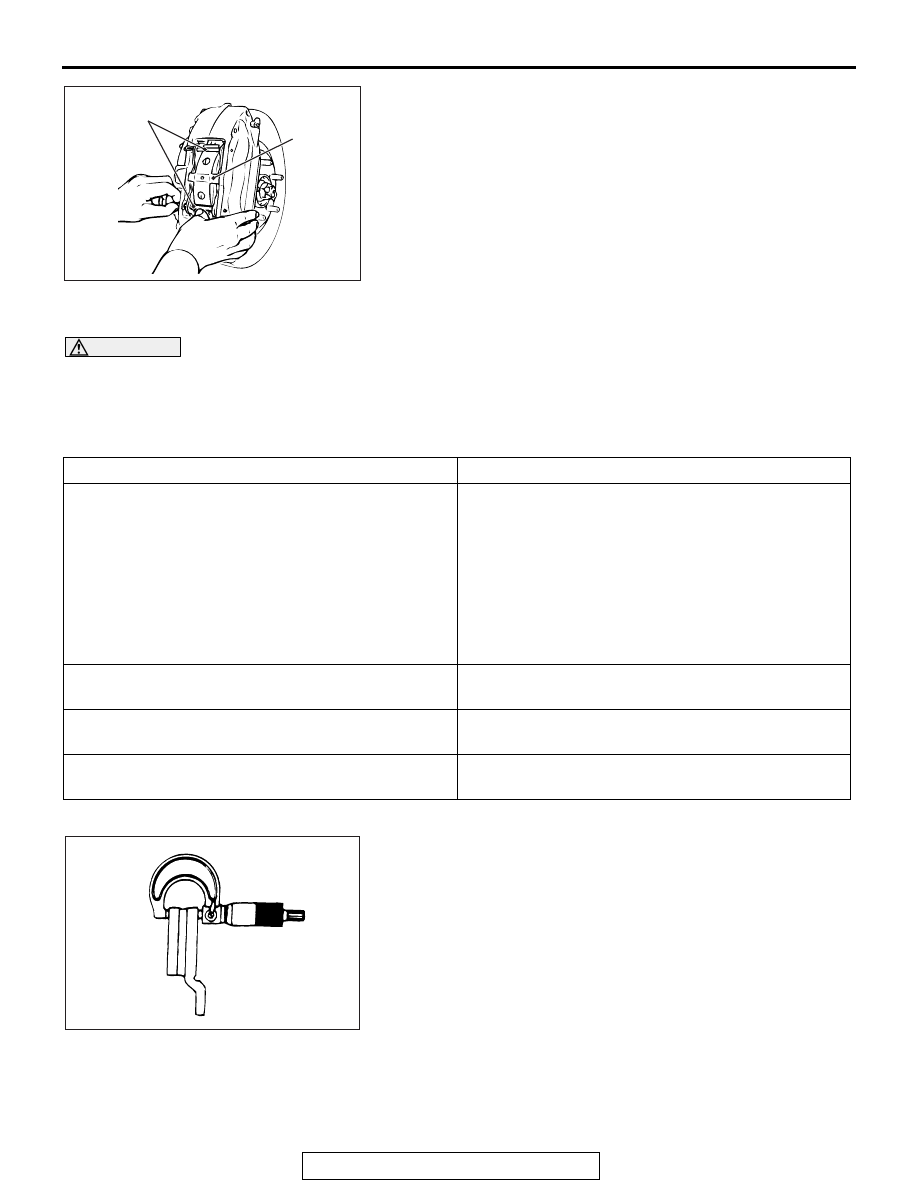

1. Using a micrometer, measure disk thickness at eight

positions, approximately 45 degrees apart and 10 mm (0.4

inch) in from the outer edge of the disk.

Standard value:

32.0 mm (1.26 inch) <Front>

22.0 mm (0.87 inch) <Rear>

Limit:

30.0 mm (1.18 inch) <Front>

20.0 mm (0.79 inch) <Rear>

NOTE: Thickness variation (at least 8 positions) should not

be more than 0.015 mm (0.0006 inch).

AC211990AC

Cross

spring

Pin

Inspection item

Remark

Scratches, rust, saturated lining materials and wear

• If the vehicle is not driven for a long period of

time, sections of the disks that are not in contact

with the pads will become rusty, causing noise

and shuddering.

• If grooves and scratches resulting from excessive

disk wear are not removed prior to installing a new

pad assembly, there will be inadequate contact

between the disk and the lining (pad) until the

pads conform to the disk.

Run-out

Excessive run-out of the disks will increase the pedal

depression resistance due to piston kick-back.

Change in thickness (parallelism)

If the thickness of the disk changes, this will cause

pedal pulsation, shuddering and surging.

Inset or warping (flatness)

Overheating and improper handling while servicing

will cause warping or distortion.

ACX00668AB