Mitsubishi Lancer Evolution X. Manual - part 121

EMISSION CONTROL <MFI - T/C>

TSB Revision

ENGINE AND EMISSION CONTROL

17-71

VACUUM HOSE INSTALLATION

M1173007200486

1. When connecting the vacuum hoses, they should be

securely inserted onto the nipples.

2. Connect the hoses correctly, using the VACUUM HOSE

ROUTING diagram as a guide.

VACUUM HOSE CHECK

M1173007300762

1. Using the VACUUM HOSE ROUTING diagram as a guide,

check that the vacuum hoses are correctly connected.

2. Check the connection condition of the vacuum hoses which

can be removed, loosened, clogged possibly. And then

check whether there are no folded and damaged vacuum

hoses.

POSITIVE CRANKCASE VENTILATION SYSTEM

GENERAL INFORMATION (POSITIVE CRANKCASE VENTILATION SYSTEM)

M1173005001199

The positive crankcase ventilation (PCV) system pre-

vents the escape of blow-by gases from inside the

crankcase into the atmosphere.

Fresh air is sent from the air cleaner into the crank-

case through the breather hose to be mixed with the

blow-by gas inside the crankcase.

The blow-by gas inside the crankcase is drawn into

the intake manifold through the PCV valve.

The PCV valve is designed to lift the plunger accord-

ing to the intake manifold vacuum so as to regulate

the flow of blow-by gas properly.

In other words, the blow-by gas flow is regulated dur-

ing low load engine operation to maintain engine sta-

bility, while the flow is increased during high load

operation to improve the ventilation performance.

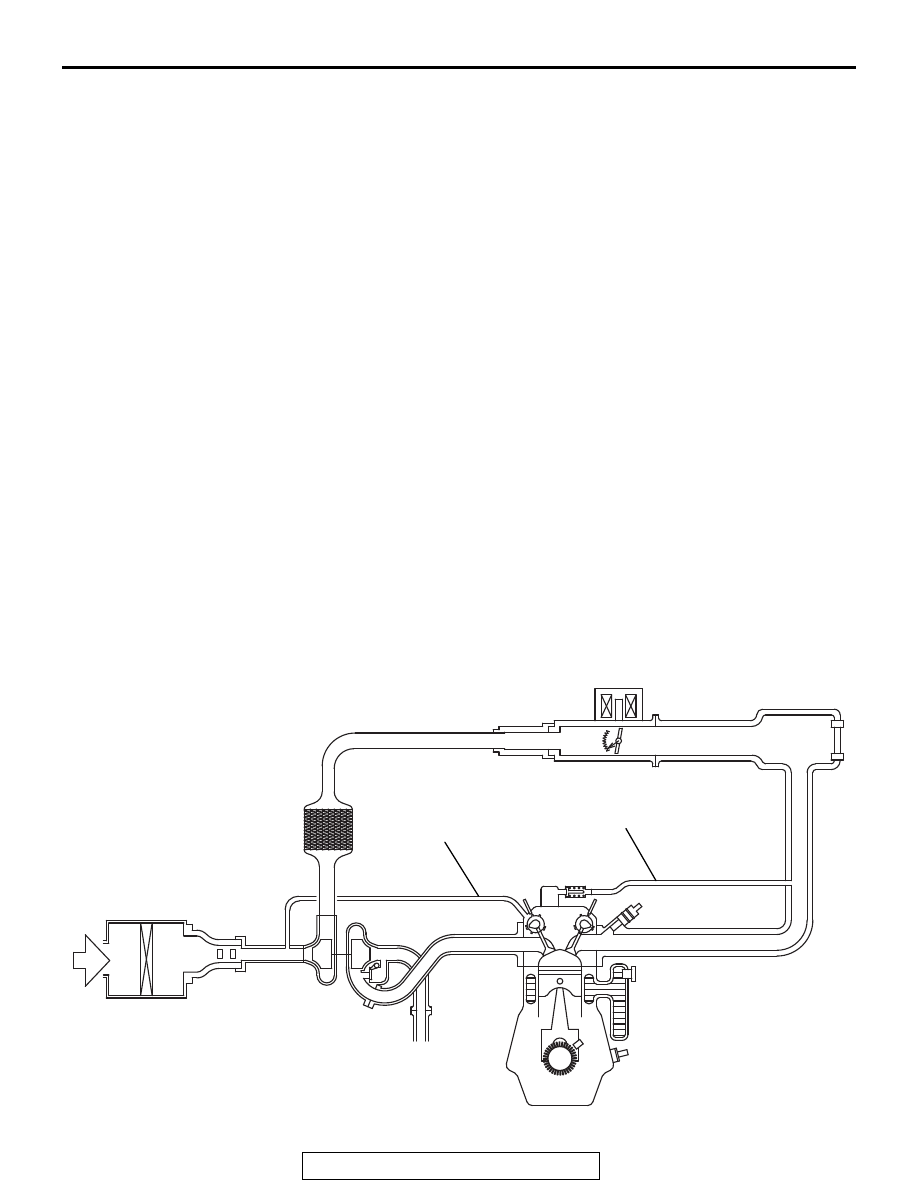

SYSTEM DIAGRAM

AK703398 AD

Air cleaner

Positive crankcase

ventilation valve

Ventilation hose

Breather hose