Mitsubishi Lancer Evolution X. Manual - part 77

CYLINDER HEAD GASKET

TSB Revision

ENGINE MECHANICAL

11A-61

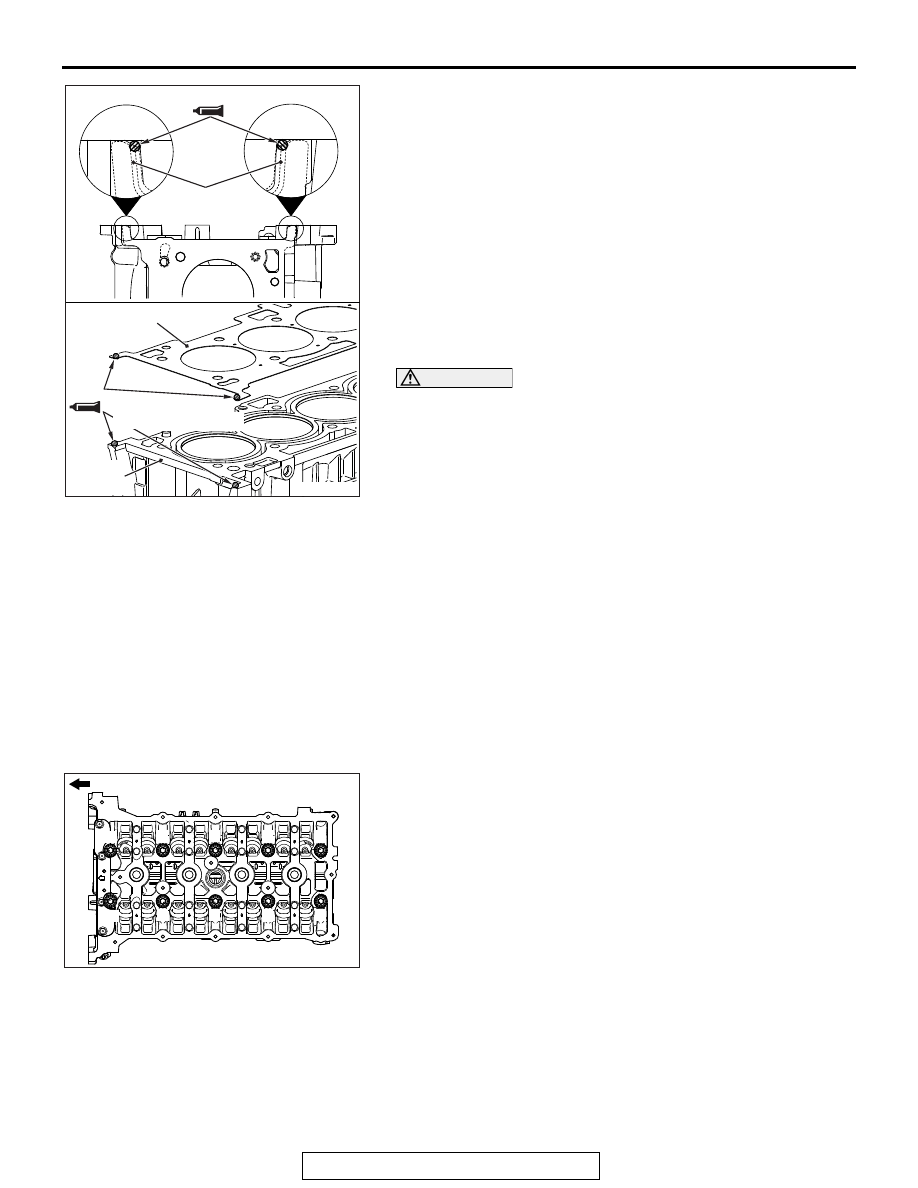

2. Apply the sealant to the top surface of cylinder block as

shown in the figure.

Specified sealant: Three bond 1217G or equivalent

3. Install the cylinder head gasket to the cylinder block.

NOTE:

.

•

Install the cylinder head gasket immediately after apply-

ing sealant.

•

When the cylinder gasket is installed to the cylinder

block, check that the sealant is securely applied to the

bead line of the cylinder head gasket.

4. Apply the sealant to the top surface of cylinder head gasket

as shown in the figure.

Specified sealant: Three bond 1217G or equivalent

CAUTION

After the installation, until a sufficient period of time (one

hour or more) elapses, do not apply the oil or water to the

sealant application area or start the engine.

5. Within three minutes after the sealant application, install the

cylinder head assembly.

.

>>B<< CYLINDER HEAD BOLT AND WASHER

ASSEMBLY/CYLINDER HEAD BOLT

WASHER/CYLINDER HEAD BOLT INSTALLATION

1. Replace the cylinder head bolt and washer with new ones.

2. For two bolts of the timing chain side, the washer can be

removed from the bolt. Install the washer, with its sag facing

upward, to the bolts.

3. Apply a small amount of engine oil to the thread of the bolts

and to the washers.

4. Tighten the bolts by the following procedure (plastic region

angular tightening method).

(1) Tighten the bolts to 35 ± 2 N⋅ m (26 ± 1 ft-lb) in the order

of number shown in the figure.

AC511063

AD

φ 2 mm or φ 3 mm (φ 0.08 in or φ 0.12 in)

Cylinder head

gasket

Cylinder head

gasket

Cylinder

block

φ 2 mm or φ 3 mm

(

φ 0.08 in or φ 0.12 in)

AC506767AE

1

2

3

4

5

6

7

8

9

10

Engine front