Mitsubishi Lancer Evolution 8 MR. Manual - part 2

1-1

ENGINE (4G6) – GENERAL

SECTION 1

CONTENTS

General ....................................................1-1

1. Major Specifications ....................................1-1

2. Engine Performance Curve.........................1-2

Base Engine (6 M/T) ...............................1-2

1. Cylinder head gasket...................................1-2

2. Pistons ..........................................................1-3

3. Piston rings (2nd) ........................................1-3

4. Oil rings ........................................................1-4

5. Counterbalance shaft .................................1-4

6. Camshaft.......................................................1-5

Intake / Exhaust System (6 M/T)............1-6

1. Exhaust system ...........................................1-6

Control system (6 M/T)...........................1-8

1. Supercharging pressure control ..............1-10

General

The 4G63-T/C engine fitted in the Lancer Evolution VIII MR is basically the same as the 4G63-T/C engine used in the Lancer

Evolution VIII.

The basic structure is the same in both the 6M/T (6-speed) and 5M/T (5-speed) versions, but the following improvements have

been made to the 6M/T version, in order to achieve higher performance.

• Adoption of 5-ply cylinder head gasket

• Addition of V-shaped groove in piston , and modified shape in cooling channel

• Reduced oil consumption by increasing tension in piston rings and reducing end-to-end gap

• Extra durability and reduced oil consumption by using new treatment on outer surface of oil ring side rail, and altering

thickness

• Lighter counterbalance shaft

• Increased output at high engine speeds by modifying intake cams

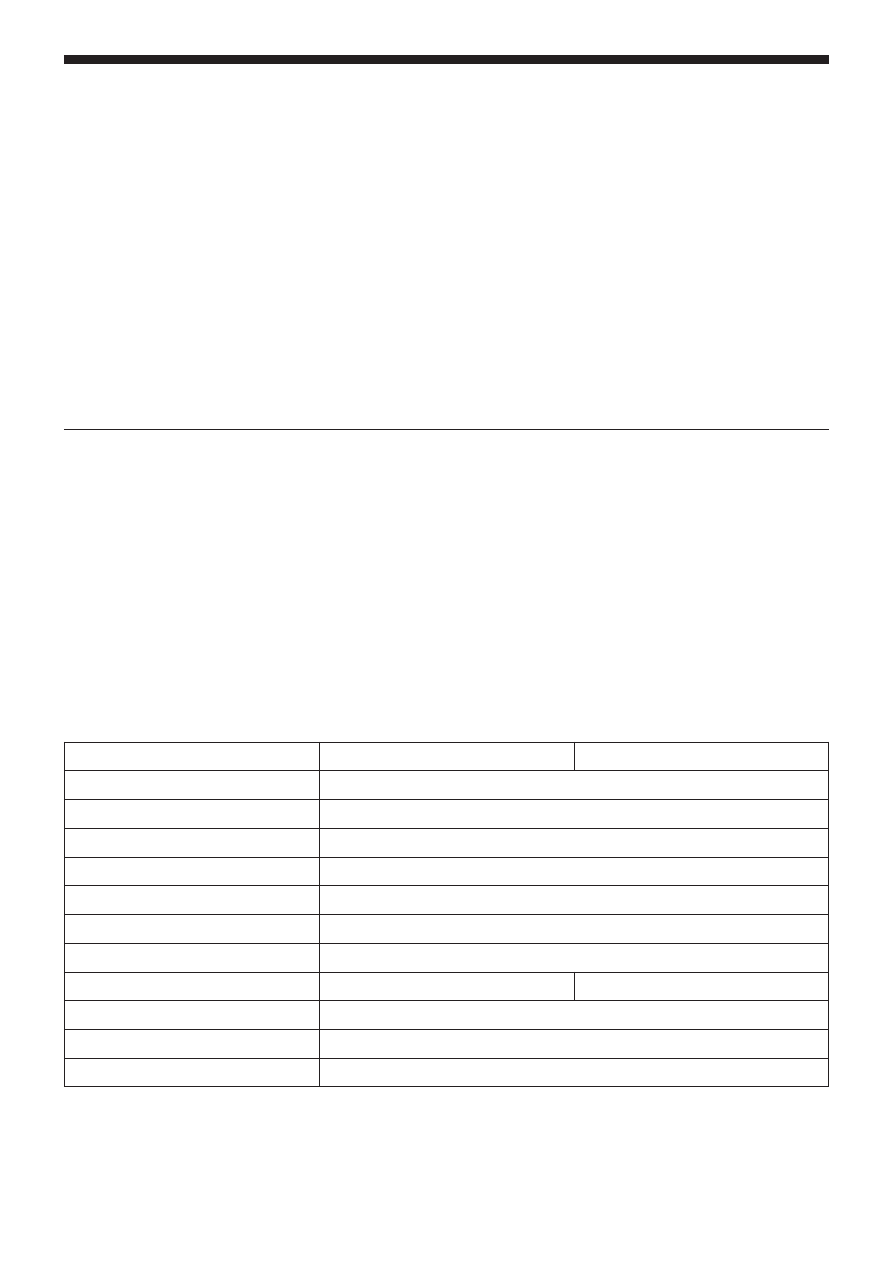

Major Specifications

Item

6 M/T

5M/T

Total Displacement cc

1997

Combustion chamber

Pentroof type

Bore x stroke (mm)

85.0 x 88.0

Compression ratio

8.8

Camshaft arrangement

DOHC-4 valve

Fuel

Premium unleaded

Max. output (kW/rpm)

206/6500

Max. torque (Nm/rpm)

400/3500

392/3500

Fuel system

Electronic controlled multipoint fuel injection

Ignition system

Electronic controlled two-coil

Lash adjuster

Equipped