Mitsubishi Lancer Evolution VI. Manual - part 67

ABS –

Troubleshooting

35B-18

<EVOLUTION-IV>

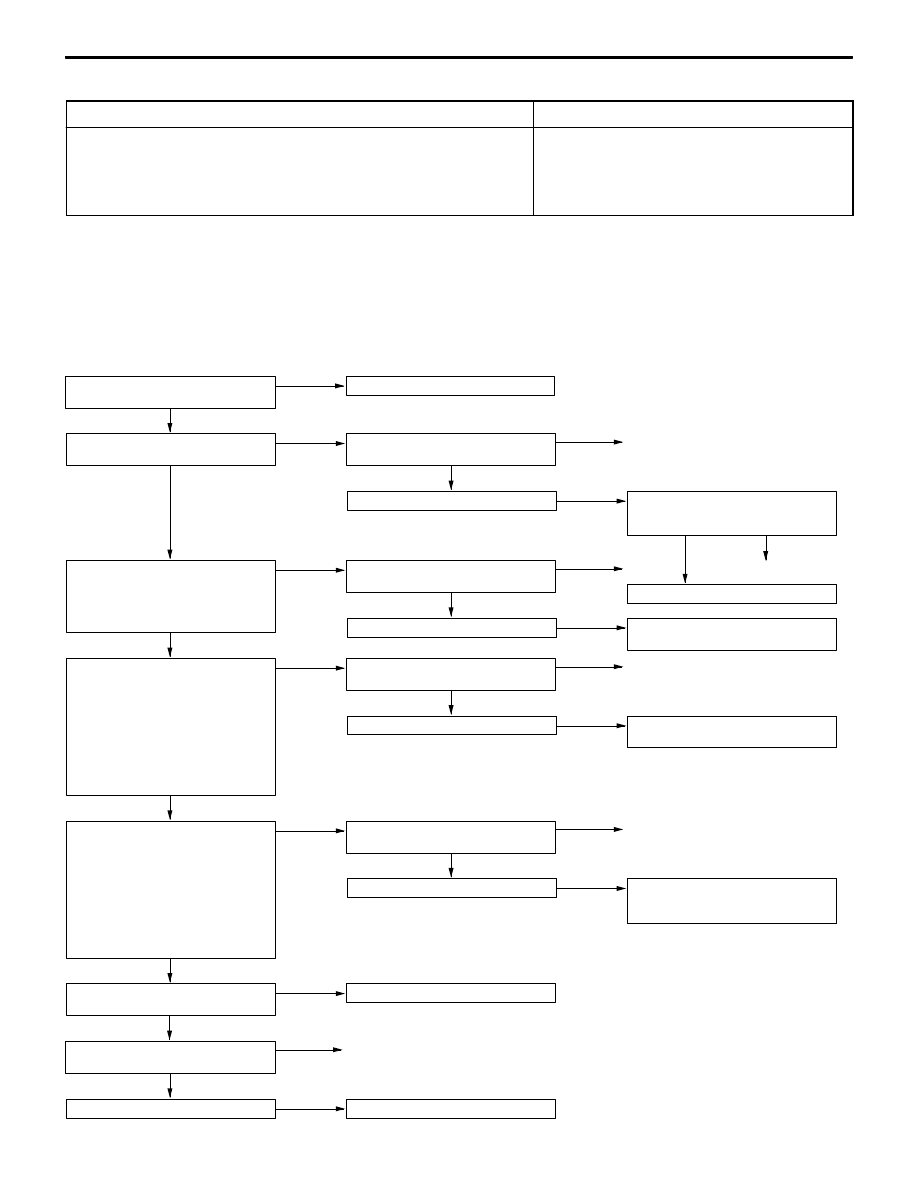

Code No.53 Motor relay system

Probable cause

This code is output under any of the following conditions:

D

No signals are input to the motor monitor when the motor relay is ON (motor

does not run, etc.).

D

A signal is being input to the motor monitor for 3 sec. or more when the motor

relay is OFF (motor continues running, etc.).

D

The motor relay is inoperative.

D

Defective motor relay

D

Defective harness or connector

D

Defective hydraulic unit

D

Defective ABS-ECU

Caution

(1) If the motor relay contacts fuse, the motor continues running even when the ignition switch

is turned OFF. In this case, immediately remove fusible link No. 8 (60 A) or disconnect the

A-22 hydraulic unit connector or A-77 motor relay connector. Overloading the motor results

in a rundown battery.

(2) Driving the motor through actuator test runs down the battery. After the test, run the engine

for some while.

OK

Check the trouble symptom.

NG

Check and repair the harness between

fusible link No. 8 and motor relay.

OK

Check the trouble symptom.

NG

Check and repair the harness between

motor relay and hydraulic unit.

OK

Check the trouble symptom.

NG

Check and repair the harness between

motor relay and ABS-ECU motor

monitor terminal No. 35.

OK

Check the trouble symptom.

NG

Replace ABS-ECU.

OK

Check the following connectors:

A-22, A-77, B-25

NG

Repair

OK

Check the motor for operation.

(Refer to P.35B-43.)

NG

Replace the hydraulic unit.

OK

Measure at A-77 motor relay connector

and B-25 ABS-ECU connector.

D

Disconnect the connector and

measure at the harness side.

D

Continuity across the following

terminals

Motor relay

ABS-ECU

side

side

4

–

35

OK: Conducting

NG

Check the following connectors:

A-77, B-25

NG

Repair

OK

Measure at A-77 motor relay connector

and A-22 hydraulic unit connector.

D

Disconnect the connector and

measure at the harness side.

D

Continuity across the following

terminals

Motor relay

Hydraulic

side

unit side

4

–

12

OK: Conducting

NG

Check the following connectors:

A-22, A-77

NG

Repair

NO

Measure at A-77 motor relay connector.

D

Disconnect the connector and

measure at the harness side.

D

Voltage across 5 and body ground

OK: System voltage

NG

Check the following connector:

A-77

NG

Repair

OK

Replace ABS-ECU.

Repair

NG

OK

Check the trouble symptom.

NG

Check the harness between motor

relay and ABS-ECU motor monitor

terminal No. 35.

OK

MUT-

II

Actuator test

Motor operating sounds heard?

YES

Check the following connector:

B-25

NG

Repair

Check the motor relay.

(Refer to P.35B-39.)

NG

Replace the motor relay.