Mitsubishi Lancer Evolution VI. Manual - part 59

REAR AXLE –

Troubleshooting <AYC>

27-30

LISTING OF RESISTANCE AND CONTINUITY ACROSS CONNECTOR TERMINALS ON HARNESS

SIDE

D

Measure the resistance and check for continuity with the ignition switch in the “OFF” position and

AYC-ECU connector disconnected.

D

Measure the resistance and check for continuity across terminals listed below.

D

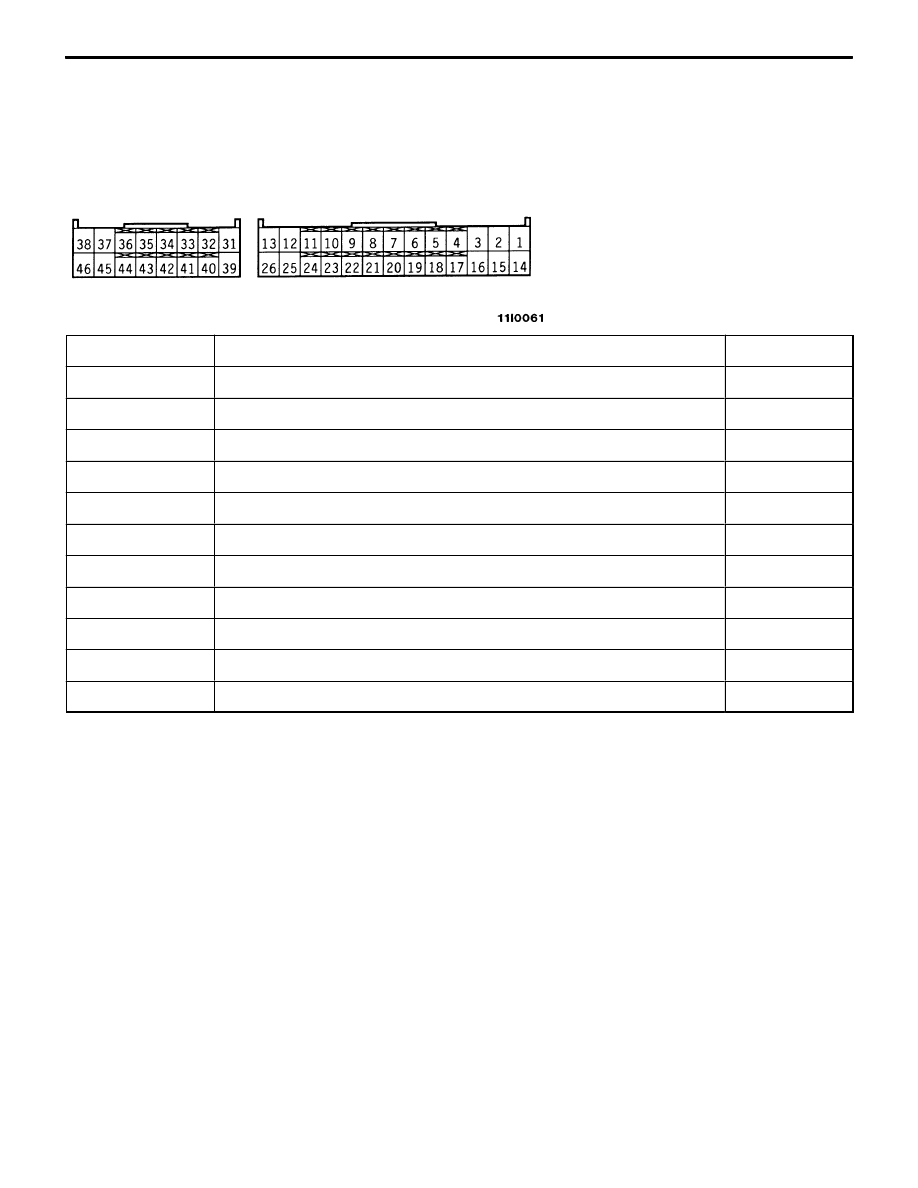

Fig. below shows the arrangement of terminals.

Terminal No.

Signal name

Normally

2 – body ground

Longitudinal acceleration sensor ground, lateral acceleration sensor ground

Conducting

26 – body ground

ECU ground

Conducting

35 – body ground

AYC motor relay

Conducting

37 – body ground

Directional control valve (right)

15.4 – 16.4

Ω

38 – body ground

Proportioning valve

3.4 – 4.0

Ω

45 – body ground

Directional control valve (left)

15.4 – 16.4

Ω

46 – body ground

ECU ground

Conducting

6 – 19*

2

Speed sensor (front, RH)

1.4 – 1.8 k

Ω

7 – 20*

2

Speed sensor (front, LH)

1.4 – 1.8 k

Ω

8 – 21*

2

Speed sensor (rear, RH)

1.4 – 1.8 k

Ω

9 – 22*

2

Speed sensor (rear, LH)

1.4 – 1.8 k

Ω

NOTE

*2: Indicates the vehicles without ABS.