Mitsubishi Lancer Evolution VI. Manual - part 23

ENGINE –

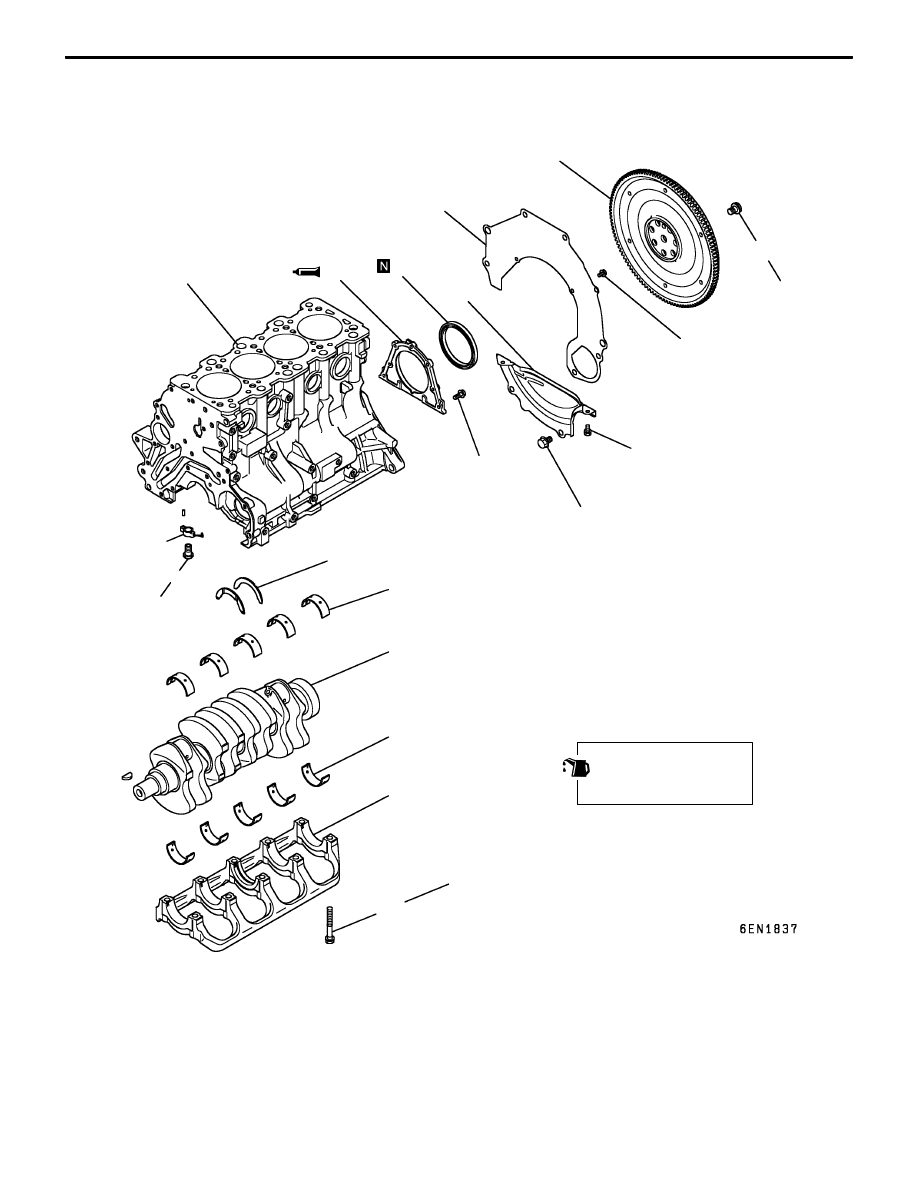

Crankshaft and Flywheel

11-67

CRANKSHAFT AND FLYWHEEL

REMOVAL AND INSTALLATION

Apply engine oil to all

moving parts before

installation.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

25 Nm + 90

_

11 Nm

132 Nm

9 Nm

11 Nm

32 Nm

11 Nm

Removal steps

1. Flywheel bolt

2. Flywheel

3. Rear plate

4. Bell housing cover

"

E

A

5. Oil seal case

"

D

A

6. Oil seal

"

C

A

7. Beam bearing cap bolt

"

C

A

8. Beam bearing cap

"

B

A

9. Crankshaft bearing lower

10. Crankshaft

"

B

A

11. Crankshaft bearing upper

"

A

A

12. Crankshaft thrust bearing

13. Check valve

14. Oil jet

15. Cylinder block