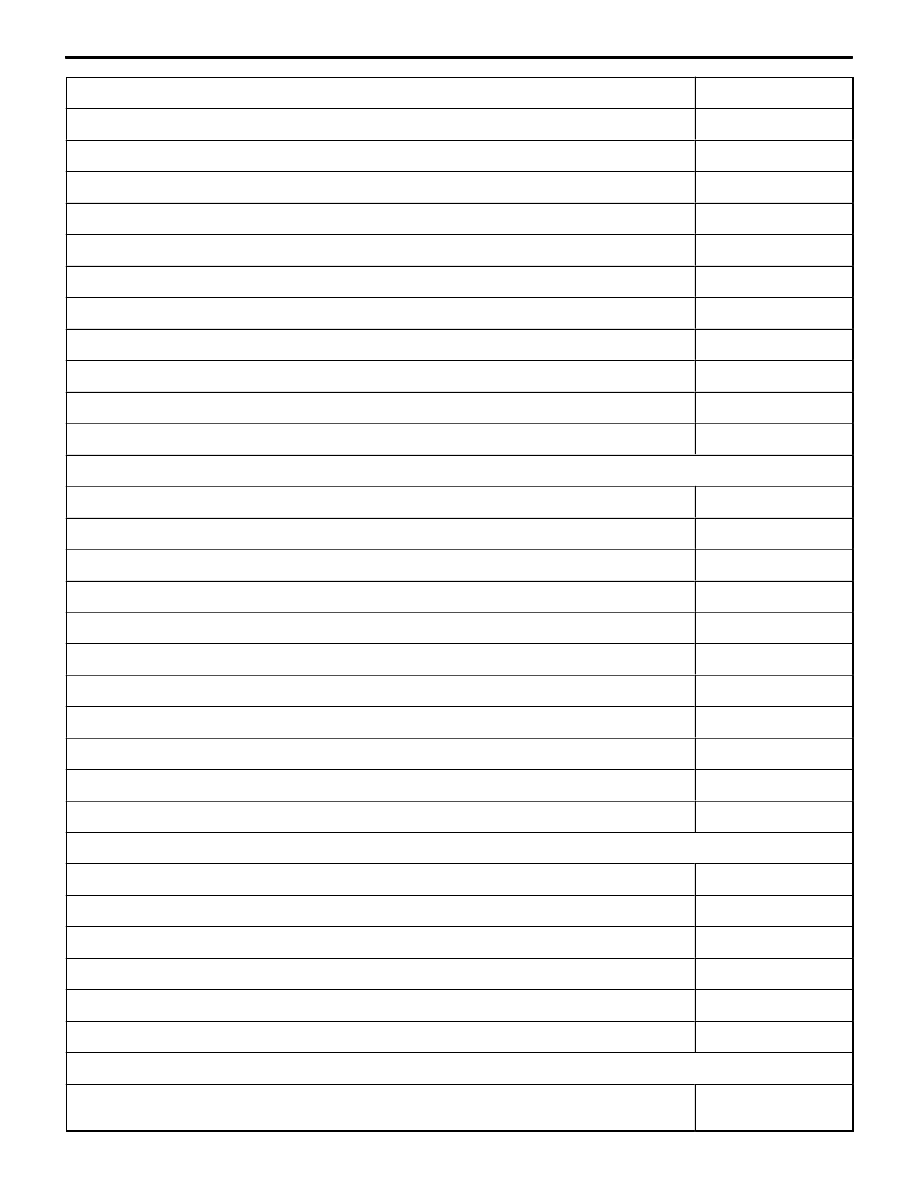

Mitsubishi Lancer Evolution VI. Manual - part 8

ENGINE –

Specifications

11-7

Items

Nm

OIl return pipe (Turbocharger side)

9

Oil return pipe (Oil pan side – Head mark 7)

9

Oil return pipe (Oil pan side – Head mark 10)

13

Oil pipe

11

Oil pipe eye bolt (Cylinder head side)

16

Oil pipe eye bolt (Turbocharger side)

30

Water pipe

11

Water pipe eye bolt

41

Exhaust manifold (M8)

29

Exhaust manifold (M10)

49

Exhaust manifold (Turbocharger side)

59

Water pump and water hose

Water temperature sensor

29

Water temperature gauge unit

11

Water inlet fitting

24

Water outlet fitting (M6)

10

Water outlet fitting (M8)

13

Thermostat housing

24

Thermostat housing (Clamp)

11

Water inlet pipe (Cylinder block)

13

Water inlet pipe (Outlet fitting)

10

Water pump

14

Knock sensor

22

Rocker arms and camshaft

Camshaft position sensor

9

Camshaft position sensor cover

10

Camshaft position sensing cylinder

21

Camshaft position sensing support

13

Camshaft bearing cap

20

Oil delivery body

11

Cylinder head and valves

Cylinder head bolt [Tighten to 78 Nm and then completely before tightening to final torque

specification]

20

!

90

°

+ 90

°