Mitsubishi Eclipse. Manual - part 728

MAINTENANCE SERVICE

TSB Revision

GENERAL

00-55

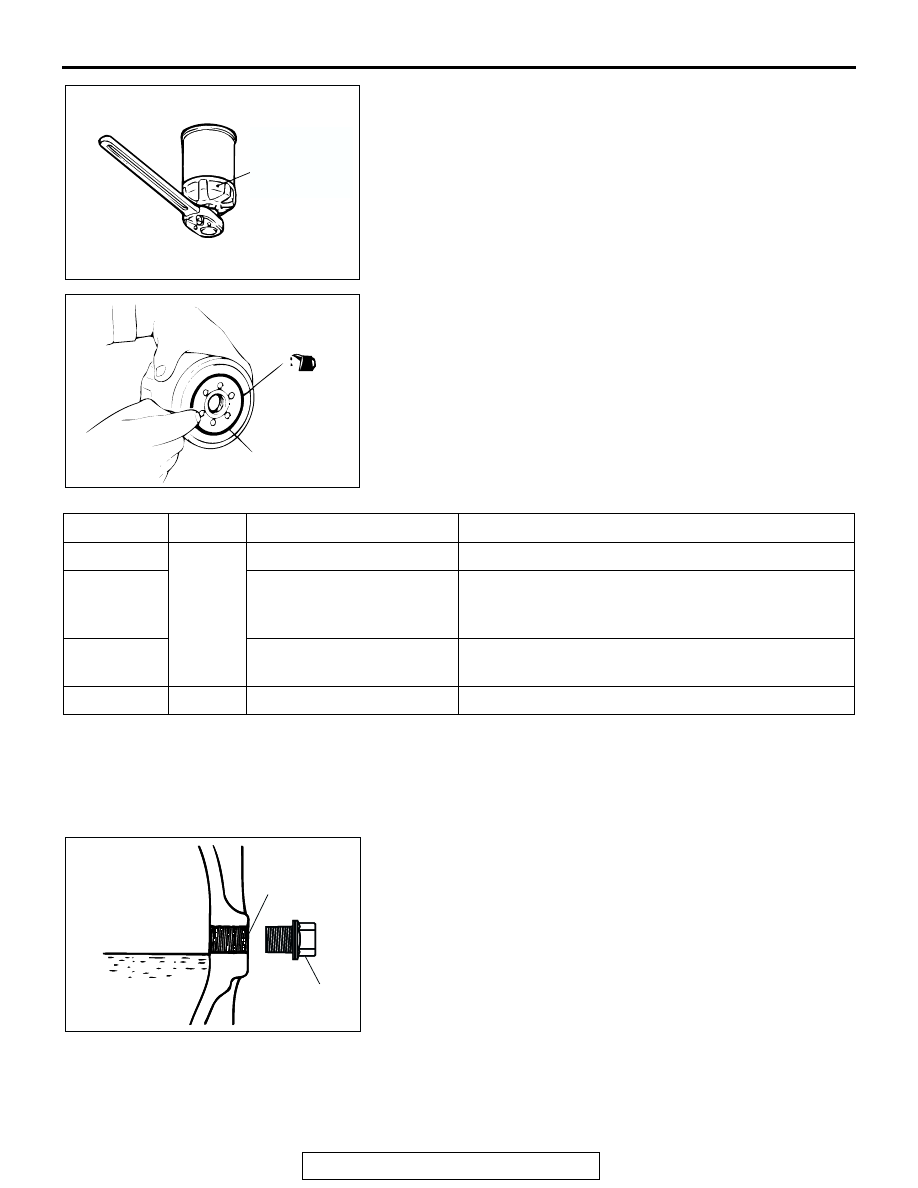

4. Use the respective tool in the following table to remove the

engine oil filter.

5. Clean the filter bracket side mounting surface and ensure

the old O-ring has been removed.

6. Apply a small amount of engine oil to the O-ring of the new

oil filter.

7. Once the O-ring of the oil filter is touching the flange, use the

respective tool in the following table to tighten to the

specified torque.

8. Install the drain plug and refill engine oil. (Refer to Engine

Oil Replacement

.)

9. Race the engine a few times, and check to be sure that no

engine oil leaks from the installation section of the oil filter.

12. MANUAL TRANSAXLE OIL

M1001002800201

Inspect each component for evidence of leakage. Check the oil

level by removing the filler plug.

CEHCK OIL LEVEL

1. Remove the filler plug.

2. Check that the oil level is up to the lower edge of the filler

plug hole.

3. Check that the oil is not noticeably dirty.

4. Tighten the filler plug to the specified torque.

Tightening torque: 32

± 2 N⋅m (24 ± 1 ft-lb)

AC000093

MB991396 OR

GENERAL

SERVICE

TOOL

AE

ACX00396

O-RING

AB

NUMBER

ENGINE SPECIAL TOOL

TIGHTENING TORQUE

MD360935

2.4L

MB991396 or equivalent

Approximately one turn [14

± 2 N⋅m (124 ± 18 in-lb)]

MD325714,

MD332687,

MD365876

MB991396 or equivalent

Approximately 3/4 turn [16

± 4 N⋅m (12 ± 3 ft-lb)]

MD136466,

MD322508

General service tool

Approximately 3/4 turn [17

± 3 N⋅m (13 ± 2 ft-lb)]

MD352626

3.0L

General service tool

Approximately 3/4 turn [14

± 2 N⋅m (124 ± 18 in-lb)]

AC102278

AC102278AC

FILLER PLUG

TRANSAXLE

OIL

FILLER PLUG

HOLE