Mitsubishi Eclipse. Manual - part 497

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.0L>

13B-531

DTC SET CONDITIONS

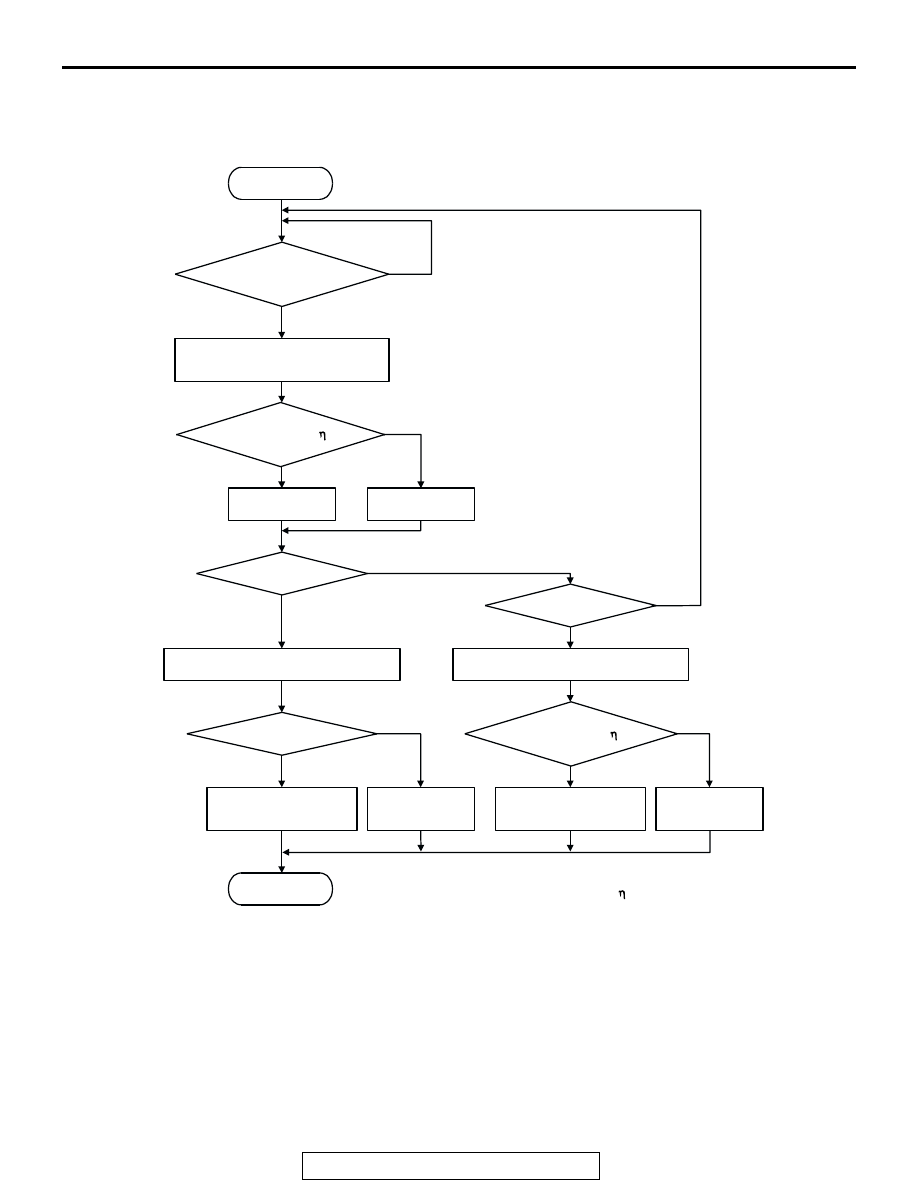

Logic Flow Chart

.

Check Conditions

• Engine speed is between 440 and 6,000 r/min.

• Engine coolant temperature is higher than −10°C

(14

°F).

• Intake air temperature is higher than −10°C

(14

°F).

• Barometric pressure is higher than 76 kPa (11

psi).

• Volumetric efficiency is at between 30 and 60

percent.

• Adaptive learning is complete for the vane which

generates a crankshaft position signal.

• While the engine is running, excluding gear shift-

ing, deceleration, sudden acceleration/decelera-

tion and A/C compressor switching.

START

MONITORING

CONDITIONS

CALCULATE CRANKSHAFT

ANGULAR ACCELERATION (An)

A

N

< TH

MF

(Ne, v)

MISFIRE

CALCULATE PERCENT MISFIRE (R

MF

)

END

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

GOOD

WITHIN 1000rev

R

MF

> SPECIFIED VALUE

MALFUNCTION

(EXCEED STD ×1.5)

GOOD

MALFUNCTION

(DAMAGE THE CAT.)

GOOD

R

MF

> TH

CD

(Ne, v)

CALCULATE PERCENT MISFIRE (R

MF

)

WITHIN 200rev

Ne: ENGINE SPEED

v: VOLUMETRIC EFFICIENCY

AK302602