Mitsubishi Eclipse. Manual - part 272

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L>

13A-581

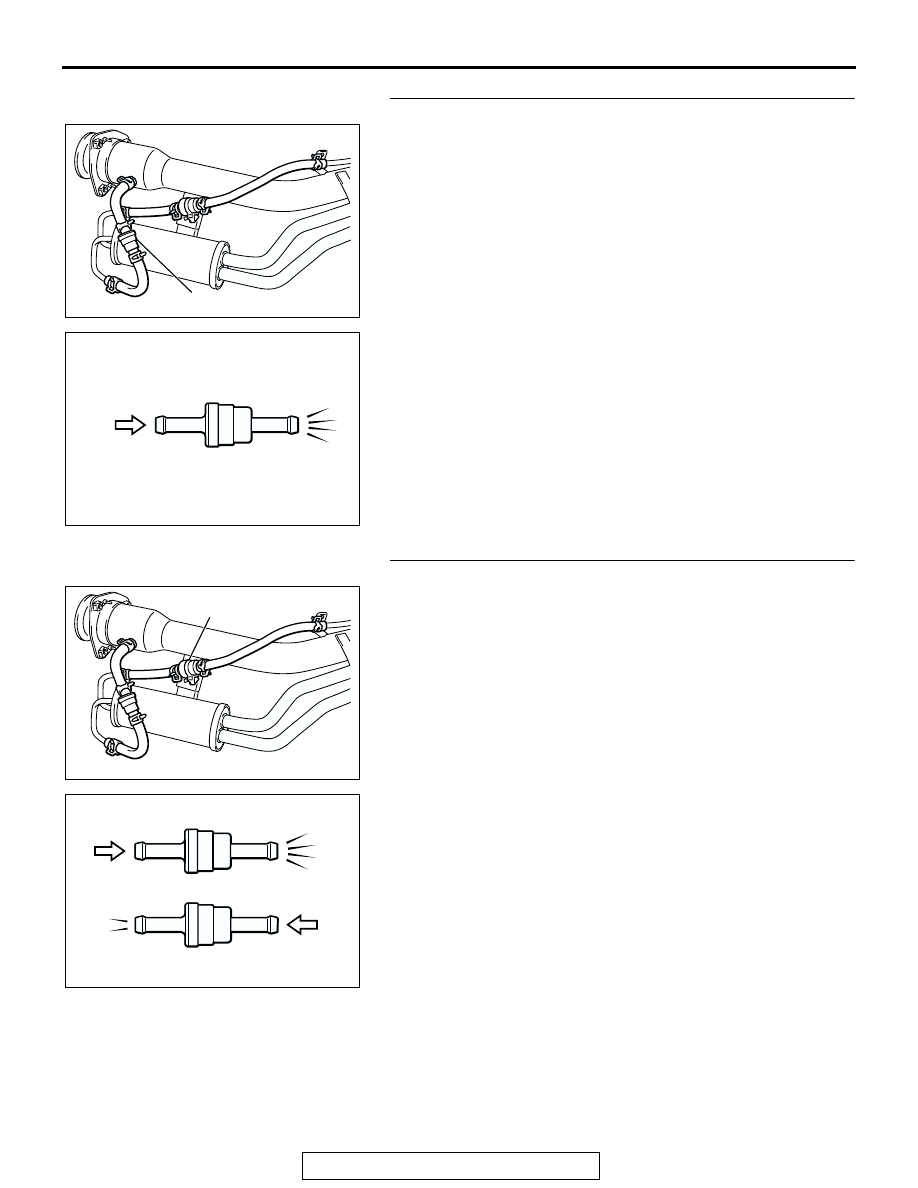

STEP 12. Check the check valve A.

(1) Only when you blow the check valve from the direction

shown, it should pass air.

(2) When you blow the check valve, air should leak from the

check valve body.

Q: Is check valve A in good condition?

YES : Go to Step 13.

NO : Replace the check valve A, and reinstall the filler neck

assembly. (Refer to GROUP 13C, Fuel Tank

.) Then go to Step 27.

STEP 13. Check the check valve B.

(1) When you blow the check valve from the arrow direction

shown above, it should pass more air.

(2) When you blow the check valve from the arrow direction

shown below, it should pass less air.

(3) When you blow the check valve, air should leak from the

check valve body.

Q: Is check valve B in good condition?

YES : Go to Step 14.

NO : Replace the check valve B, and reinstall the filler neck

assembly. (Refer to GROUP 13C, Fuel Tank

.) Then go to Step 27.

AC002039

CHECK VALVE A

AE

AC002076 AB

CHECK VALVE A

AC002039

CHECK VALVE B

AF

AC002078

CHECK VALVE B

AB