Mitsubishi Eclipse. Manual - part 245

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L>

13A-473

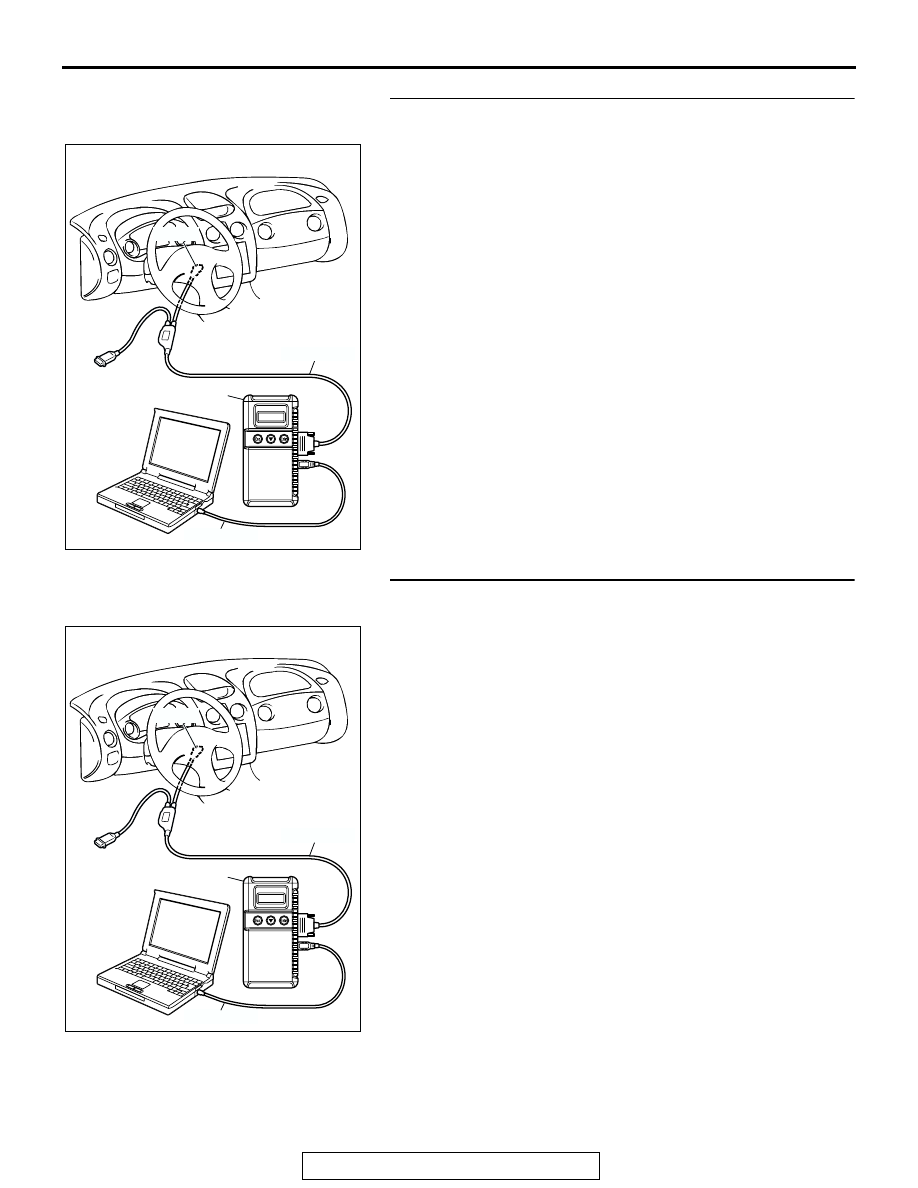

STEP 2. Using scan tool MB991958, check data list item 73:

Fuel Tank Differential Pressure Sensor.

(1) Turn the ignition switch to the "ON" position.

(2) Remove the fuel cap.

(3) Set scan tool MB991958 to the data reading mode for item

73, Fuel Tank Differential Pressure Sensor.

• The fuel tank differential pressures should be −1.5 to 1.5

kPa (

−0.44 to 0.44 in.Hg).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the solenoid operating properly?

YES : Go to Step 3.

NO : Refer to, DTC P0451 - Evaporative Emission Control

System Pressure Sensor Range/Performance

STEP 3. Using scan tool MB991958, check actuator test

item 08: Evaporative Emission Purge Solenoid.

(1) Turn the ignition switch to the "ON" position.

(2) Set scan tool MB991958 to the actuator test mode for item

08, Evaporative emission purge solenoid.

• An operation sound should be heard and vibration

should be felt when the evaporative emission purge

solenoid is operated.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the solenoid operating properly?

YES : Go to Step 4.

NO : Replace the evaporative emission purge solenoid.

Then go to Step 5.

AK300810

AB

MB991911

16-PIN

MB991827

MB991824

AK300810

AB

MB991911

16-PIN

MB991827

MB991824