Mitsubishi Eclipse. Manual - part 225

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L>

13A-393

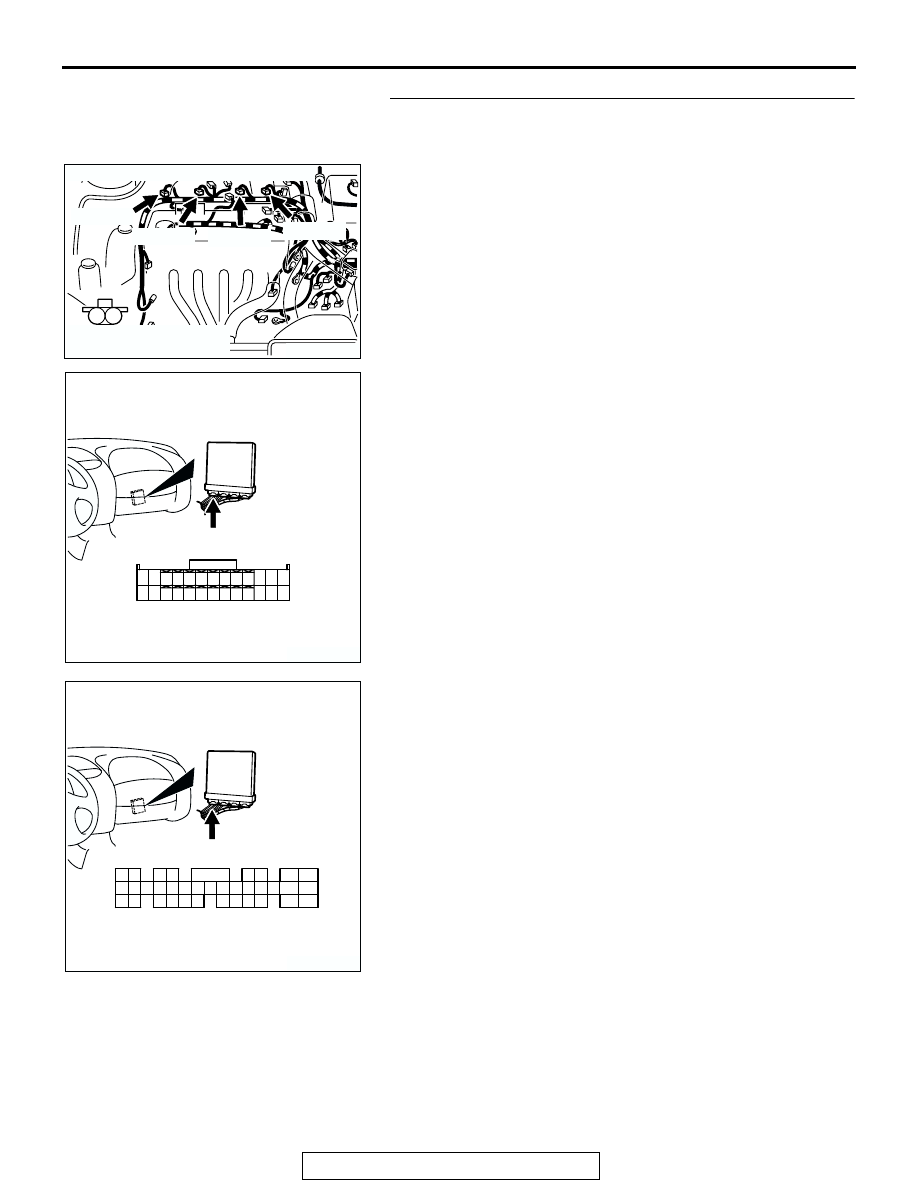

STEP 10. Check for harness damage between injector

connector and ECM connector <M/T> or PCM connector

<A/T>.

a. Check the harness wire between injector connector B-01

(terminal No. 2) and ECM connector C-49 (terminal No. 1)

<M/T> or PCM connector C-50 (terminal No. 1) <A/T> when

checking No. 1 cylinder.

b. Check the harness wire between injector connector B-02

(terminal No. 2) and ECM connector C-49 (terminal No. 14)

<M/T> or PCM connector C-50 (terminal No. 9) <A/T> when

checking No. 2 cylinder.

c. Check the harness wire between injector connector B-05

(terminal No. 2) and ECM connector C-49 (terminal No. 2)

<M/T> or PCM connector C-50 (terminal No. 24) <A/T>

when checking No. 3 cylinder.

d. Check the harness wire between injector connector B-06

(terminal No. 2) and ECM connector C-49 (terminal No. 15)

<M/T> or PCM connector C-50 (terminal No. 2) <A/T> when

checking No. 4 cylinder.

Q: Is the harness wire in good condition?

YES : Go to Step 11.

NO : Repair it. Then go to Step 13.

AK300737

1

2

CONNECTORS: B-01, B-02, B-05, B-06

AB

B-02 (GR)

B-01 (GR)

B-05 (GR)

B-06 (GR)

HARNESS CONNECTOR:

COMPONENT SIDE

AK300413

1

14

4

19

5

22

6

17

8

15

9

18

7

20

16

2

21

23

26

24

25

3

10

11

12

13

CONNECTOR: C-49 <M/T>

C-49 (G)

AB

HARNESS CONNECTOR:

COMPONENT SIDE

AK300414

2

3

4

5

6

7

8

9

11

12

13

14

15

16

17

18

19

20

30

21

22

23

24

25

26

27

28

29

31

32

33

34

35

1

10

C-50 (GR)

CONNECTOR: C-50 <A/T>

AB

HARNESS CONNECTOR:

COMPONENT SIDE