Mitsubishi Eclipse. Manual - part 115

ON-VEHICLE SERVICE

TSB Revision

ENGINE MECHANICAL <3.0L>

11C-9

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

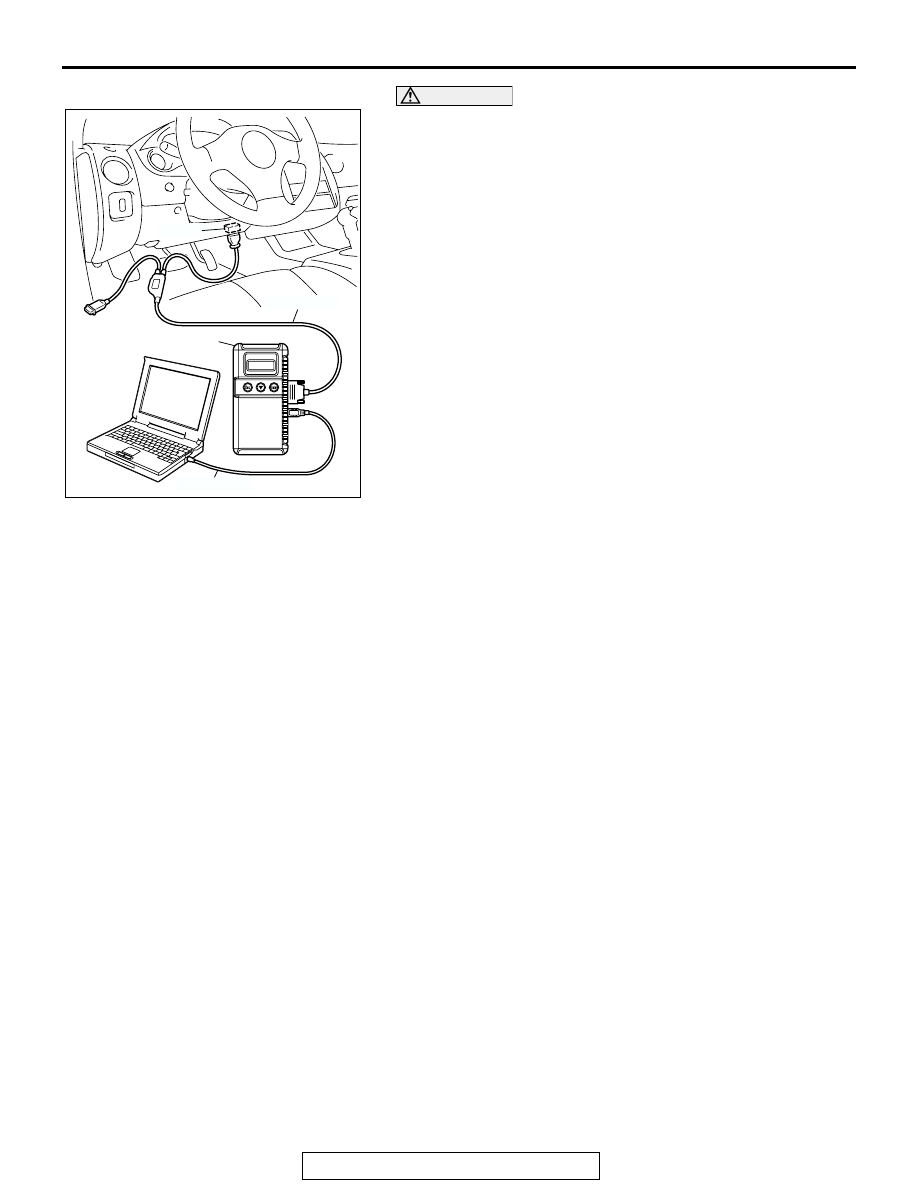

2. Connect scan tool MB991958 to the data link connector.

3. Check that the basic ignition timing is within the standard

value.

Standard value: 5

° BTDC ± 3°

4. Start the engine and increase the engine speed to 2,500

r/min for 2 minutes.

5. Set the CO, HC tester.

6. Check the CO contents and the HC contents at idle.

Standard value:

CO contents: 0.5 % or less

HC contents: 100 ppm or less

7. If the CO and HC contents do not remain inside the standard

value, check the following items:

NOTE: Replace the catalytic converter when the CO and HC

contents do not remain inside the standard value, even

though the result of the inspection is normal for all items.

• Diagnostic output

• Closed-loop control (When the closed-loop control is carried

out normally, the output signal of the heated oxygen sensor

changes between 0

− 400 mV and 600 − 1,000 mV at idle.)

• Fuel pressures

• Injector

• Ignition coil, spark plug cable, spark plug

• EGR system and EGR valve leak

• Evaporative emission system

• Compression pressure

CURB IDLE SPEED CHECK

M1111003500524

Required Special Tool:

MB991958: Scan Tool (MUT-III Sub Assembly)

• MB991824: V.I.C.

• MB991827: USB Cable

• MB991911: Main Harness B

1. Before inspection and adjustment set vehicles in the

following condition.

• Engine coolant temperature: 80 − 95°C (176 − 203°F)

• Lights and all accessories: OFF

• Transaxle: Neutral (P range on vehicles with A/T)

AK301853

AB

MB991911

16-PIN

MB991827

MB991824