Mitsubishi Eclipse. Manual - part 111

TIMING BELT

TSB Revision

ENGINE MECHANICAL <2.4L>

11A-39

REMOVAL SERVICE POINT

.

<<A>> TIMING BELT REMOVAL

CAUTION

The crankshaft should always be turned in the forward

direction only.

1. Turn the crankshaft in the forward direction (to the right) to

align the camshaft sprocket timing marks.

CAUTION

If the timing belt is to be re-used, use chalk to mark (on its

flat side) an arrow indicating the clockwise direction.

2. Loosen the tension pulley fixing bolt.

3. Move the tension pulley to the water pump side, and then

remove the timing belt.

INSTALLATION SERVICE POINTS

.

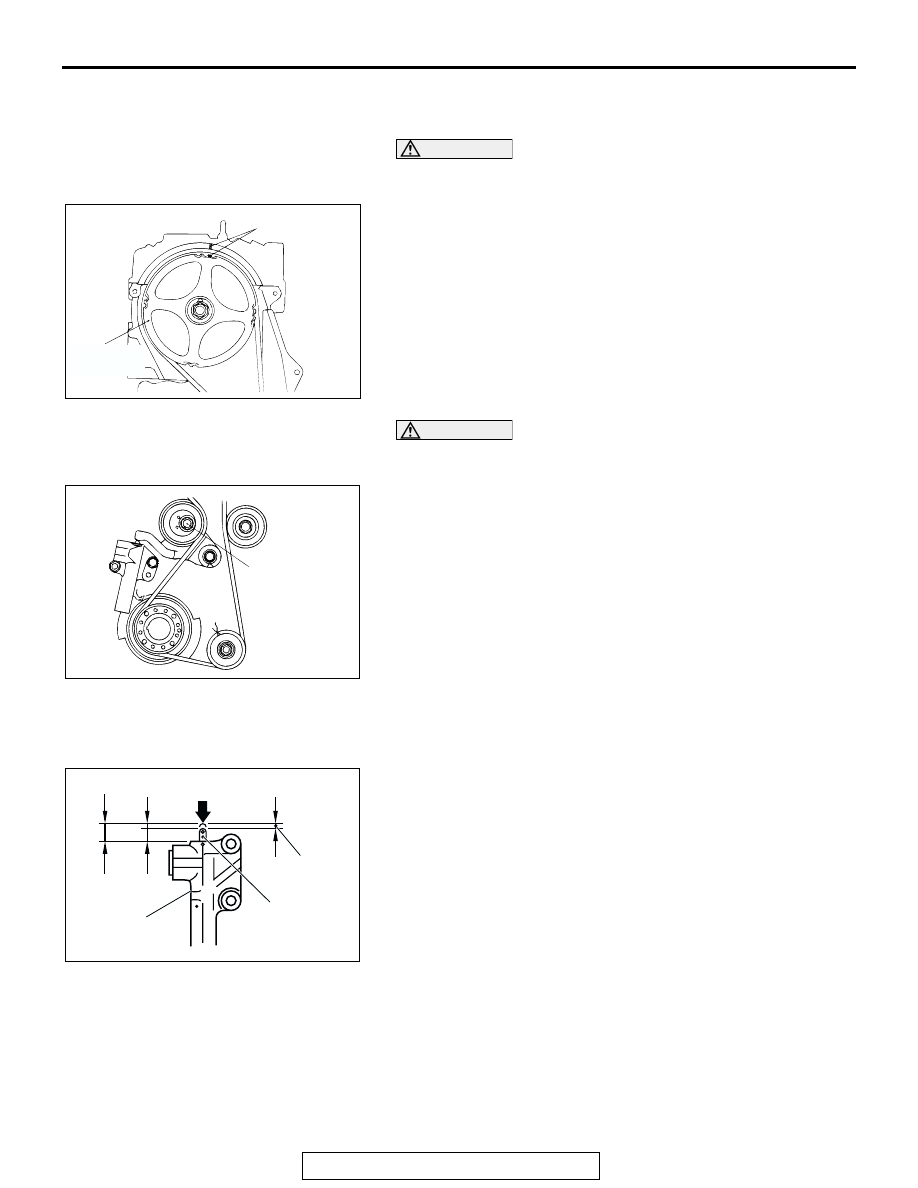

>>A<< AUTO-TENSIONER INSTALLATION

1. Apply 98

− 196 N (22 − 44 pound) force to the pushrod of the

auto-tensioner by pressing it against a metal object (such as

the engine block) and measure the movement of the

pushrod.

Standard value: Within 1 mm (0.04 inch)

A: Length when it is free (not pressed)

B: Length when it is pressed

A

− B: Movement

2. If it is outside the standard value, replace the auto-tensioner.

AC000146AB

TIMING MARKS

CAMSHAFT

SPROCKET

AC000147

FIXING BOLT

AB

ACX00306AC

A

B

AUTO-TENSIONER

AMOUNT

PUSHED IN

PUSHROD

98 – 196 N

(22 – 44 lb)