Mitsubishi Colt Ralliart. Manual - part 757

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4G1>

13B-353

Standard Wave Pattern

Observation condition

Description of Wave Pattern

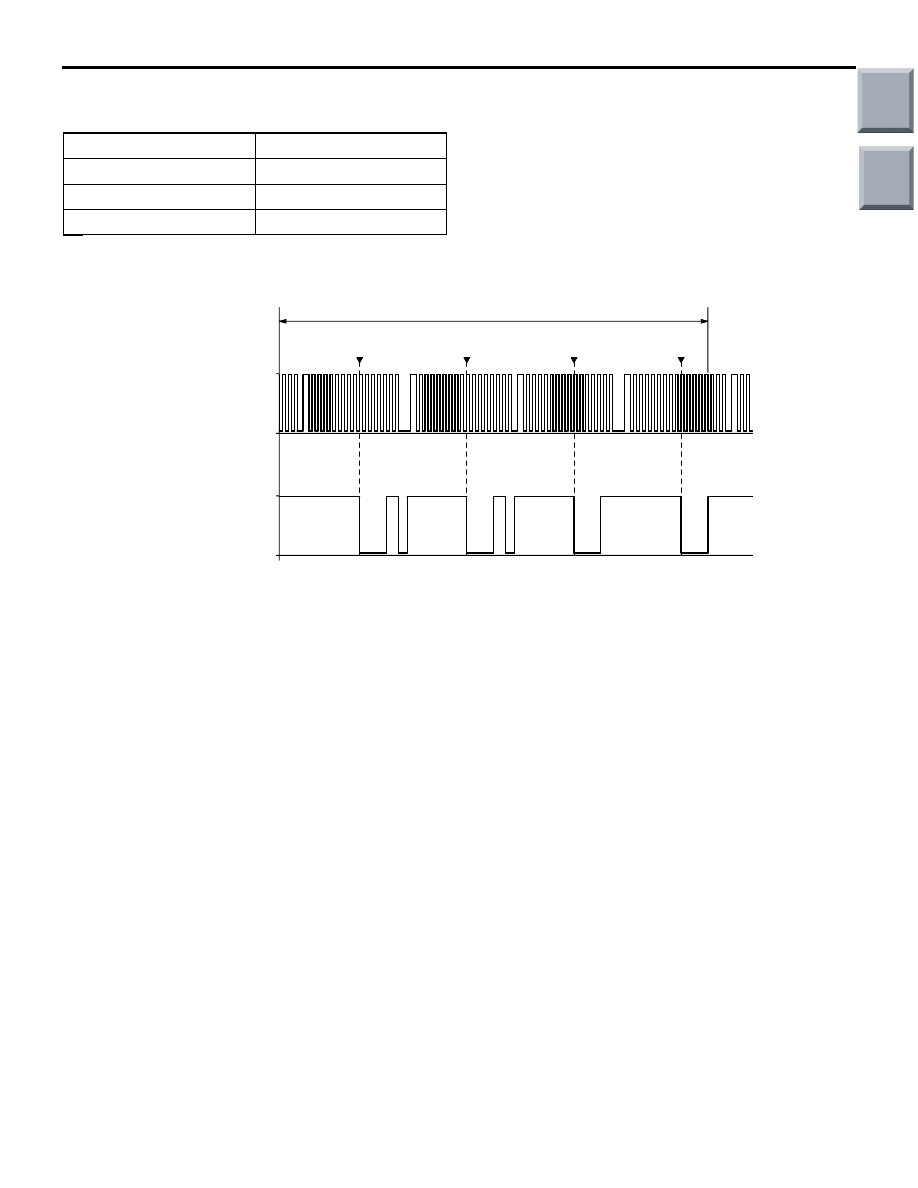

• The camshaft position sensor detects the com-

pression top dead center of each cylinder.

Observing this signal as well as other control sig-

nals simultaneously allows cylinder identification

to be achieved.

• The crank angle sensor detects the crank angle

of each cylinder. 72 crank angle sensor high sig-

nals (including missing tooth) are output at equal

spaces per two revolutions of the engine.

Wave Pattern Observation Points

• Check that the wave pattern becomes shorter

when the engine speed increases.

Function

Special patterns

Pattern height

Low

Pattern selector

Display

Engine

Idle

AK204111AC

(V)

5

0

5

0

No. 1TDC

No. 3TDC

No. 4TDC

No. 2TDC

time

Standard wave pattern

Crank angle

sensor output

wave pattern

Camshaft position

sensor output

wave pattern

2 engine revolutions

(1 camshaft revolution)

TDC: Top dead centre

Main

Index

Group

TOC