Mitsubishi Colt Ralliart. Manual - part 645

STEERING WHEEL SENSOR

ACTIVE STABILITY CONTROL SYSTEM (ASC)

35C-125

STEERING WHEEL SENSOR

REMOVAL AND INSTALLATION

M1357002800012

CAUTION

• When centring the clock spring, always remove the clock spring from the column switch in

advance. Otherwise, the sensor may be damaged.

• If the centre of the clock spring is not correctly aligned, the steering wheel may not be turned fully

or the cable inside the clock spring may be broken, causing the SRS air bag to be inoperative or

operated incorrectly.

• Before removing the steering wheel/air bag module assembly, refer to GROUP 52B − Service Pre-

cautions

and Air Bag Module Clock Spring

• When the steering wheel sensor is replaced, always carry out calibration to make ASC-ECU learn

the neutral point. (Refer to

Pre-removal operation

• Air bag module assembly and steering wheel assembly

removal (Refer to GROUP 37

− Steering Wheel

Post-installation operation

• Airbag module assembly and steering wheel assembly

installation (Refer to GROUP 37

− Steering Wheel

• Perform steering wheel calibration. (Refer to

.)

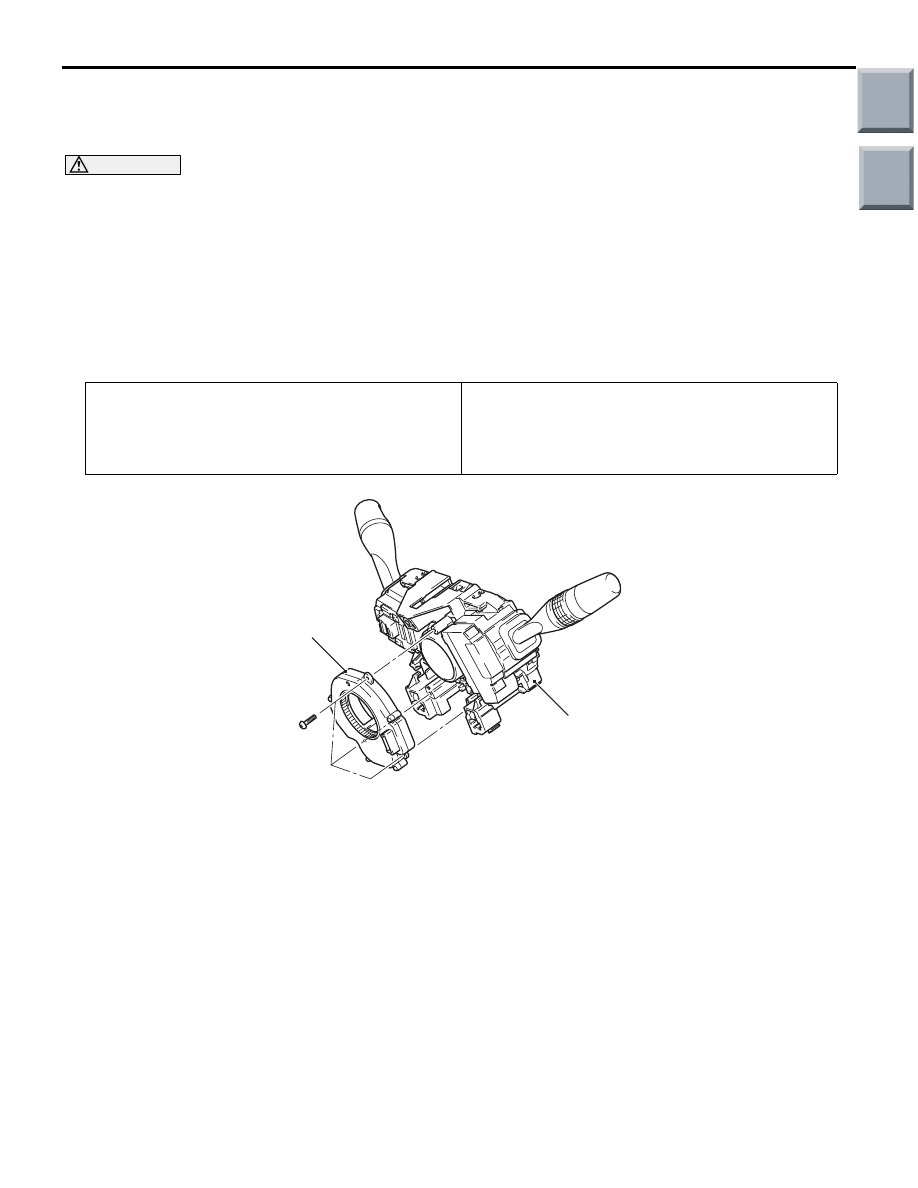

AC511706AB

1

2

Removal steps

•

Position the front wheels in a straight

ahead direction.

1. Clock spring/column switch assembly

(Refer to GROUP 52B

− SRS Control

Unit

2. Steering wheel sensor

Removal steps (Continued)

Main

Index

Group

TOC