Mitsubishi Colt Ralliart. Manual - part 610

OIL PAN AND OIL PUMP

ENGINE OVERHAUL <4G1>

11D-40

REMOVAL SERVICE POINT

<<A>> OIL PAN REMOVAL

AK201793AC

MD998727

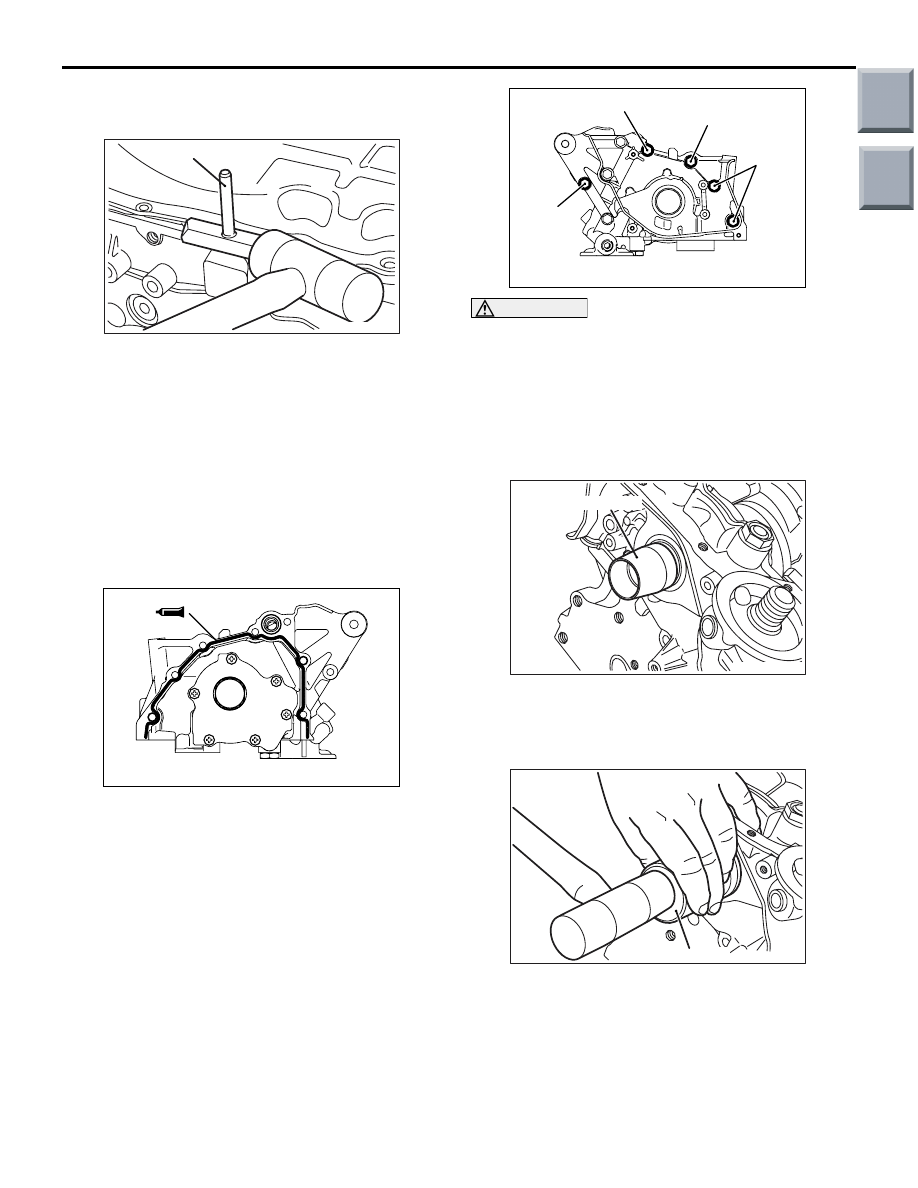

1. Remove the oil pan mounting bolts.

2. Knock the special tool Oil pan remover

(MD998727) between the oil pan and cylinder

block as shown in the illustration.

3. Tapping the side of the special tool, slide the tool

along the oil pan/cylinder block seal and thus

remove the oil pan.

INSTALLATION SERVICE POINTS

>>A<< OIL PUMP CASE INSTALLATION

AK401834AC

1. Completely remove existing form-in-place gasket

from the cylinder block (oil pump case mounting

surface) and oil pump case.

2. Apply a 3

± 1 mm bead of form-in-place gasket to

the oil pump case at the positions shown in the

illustration.

Specified sealant:

Mitsubishi Genuine Part No. 970389 or equiva-

lent

AK401833 AC

M8 × 50

M8 × 30

M8 × 20

M8 × 32

CAUTION

The mounting bolts are different in length. Take

care not to use wrong bolts in wrong places.

3. Install the oil pump case to the cylinder head, and

tighten mounting bolts to a specified torque of 14

± 1 N⋅m.

>>B<< FRONT OIL SEAL INSTALLATION

AK201796AC

MB991962

1. Place the special tool Crankshaft front oil seal

guide (MB991962) on the crankshaft's front end

and apply engine oil to the its outer

circumference.

AK201797AC

MD998306

2. Apply engine oil to the oil seal lip, then push the

oil seal along the guide by hand until it touches

the front case. Tap the oil seal into place using the

special tool Camshaft oil seal installer

(MD998306).

Main

Index

Group

TOC